Economy & Market

Microgrids can transform cement plant energy sourcing

Published

5 months agoon

By

admin

Dr Avijit Mondal, Deputy General Manager (DGM), NTPC Energy Technology Research Alliance (NETRA), NTPC, explains in detail how power sector innovations are opening new frontiers for energy-intensive industries like cement.

As the cement sector seeks pathways to efficiency and decarbonisation, lessons from the power sector—particularly thermal and renewable energy research—are becoming indispensable. Dr Avijit Mondal, Deputy General Manager, NTPC Energy Technology Research Alliance (NETRA), NTPC, shares how innovations ranging from microgrids and biomass co-firing to CO2-to-methanol pilots and CFD modelling are reshaping cement plant energy sourcing. In this conversation, he outlines a roadmap where power plant technologies and cement operations converge to deliver cleaner, more reliable and cost-efficient production.

How does research in thermal power plants drive energy efficiency for heavy industrial loads such as cement?

Cement is India’s second-largest industrial power consumer, and every kilowatt-hour saved or sourced from cleaner energy directly lowers the cost of clinker production. Research and development in thermal power plants (TPPs) plays a critical role in achieving these gains, delivering benefits through high-efficiency generation, flexible operation, improved power quality and integrated carbon management. Most importantly proper combustion in boilers (thermal power plants) creates good quality fly ash (bottom ash), which is an important raw material for the cement industry.

Advancements such as supercritical and ultra-supercritical steam cycles, improved turbine designs and auxiliary systems with variable frequency drives on feedwater, induced-draft, and forced-draft fans lower heat rates by 1.5 per cent to 3 per cent, reducing both grid emission factors and delivered tariffs-especially during off-peak hours. Ultra-low-load stable operation enables cement plants to shift energy-intensive processes such as finish grinding and mine operations to off-peak night hours, reducing power costs. R&D in coal-quality handling-using on-belt analysers and AI-driven blending-enhances steam generator stability, reducing ramp losses and improving heat rates, which in turn minimises power price volatility for industrial users.

Power quality research, including stat-coms, synchronous condensers and harmonic filters, stabilises voltage and frequency for large drives, reducing motor losses, tripping incidents and rework in cement operations. Flexible load management and industrial demand response strategies co-developed with utilities-such as automated compressor/crusher set-backs and ‘grind-at-night, burn-by-day’ schedules-help align cement energy use with renewable-rich periods. On the thermal side, TPP waste-heat recovery concepts, air preheaters and regenerative exchangers have been adapted for cement kilns, enabling exhaust gas recovery for process heat or captive power.

Parallel work in low-NOx combustion, biomass co-firing and fuel preparation optimises kiln firing efficiency, while digitalisation and predictive analytics, pioneered in TPP operations, enhance process control, maintenance scheduling, and energy loss detection in cement plants. Cogeneration models allow direct supply of steam or heat from nearby TPPs, and joint carbon capture and utilisation research offers pathways to mineralise captured CO2 in cement or use it in curing, further reducing emissions.

The combined effect of these interventions is substantial: incremental heat-rate improvements alone can lower grid CO2 intensity by 20-40 g/kWh, while smart time-of-use alignment can cut plant power costs by 2 per cent to 4 per cent. Together, these innovations lower specific energy consumption, improve process stability, and make cement manufacturing more cost-competitive and sustainable.

What innovations in microgrids or Solar/BESS could benefit cement power sourcing microgrid architecture for cement?

Cement manufacturing is among the most energy-intensive industrial processes, with continuous high loads from kilns, grinding mills, crushers and conveyors. Integrating a hybrid behind-the-meter microgrid offers a powerful solution to improve energy efficiency, reduce power costs, and enhance operational resilience. A typical integrated cement plant can deploy a hybrid system comprising 8-15 MWp of rooftop and ground-mounted solar PV, 8-25 MW of waste heat recovery (WHR) capacity, and a Battery Energy Storage System (BESS) sized for 15-30 minutes of peak plant load. In this configuration, solar PV supplies the daytime base load for processes like grinding and material transport, WHR delivers steady baseload power for kiln and cooler exhaust, and BESS handles ramping and flicker control. The BESS also enables peak shaving during kiln starts or crusher surges, provides frequency and VAR support to safeguard large variable frequency drives (VFDs), smooths renewable fluctuations to stabilise kiln induced-draft (ID) control, and offers black-start capability for captive power systems.

The system is coordinated by an advanced Energy Management System (EMS) with process awareness. This EMS forecasts solar generation and plant load, dynamically reschedules non-critical operations such as mills, packing lines and mine conveyors into solar-rich periods, and isolates the kiln and calciner from disturbances. It can also manage load shifting strategies, such as ‘grind at day, burn at night,’ aligning with renewable-rich grid periods.

Recent innovations in industrial-scale BESS include long-duration storage (4-8 hours) to cover full or partial shifts on solar and WHR, and high-C-rate batteries capable of handling sudden restarts or process surges. Some plants also deploy DC-coupled PV + BESS configurations, which reduce inverter losses and improve round-trip efficiency compared to AC-coupled systems. Capturing curtailed renewables by storing excess solar or wind energy in BESS or using it for low priority loads such as precursing further enhances system value.

Supporting infrastructure includes microgrid-ready switchgear and fast-transfer/static breakers to enable seamless islanding from the grid without tripping large motors. The architecture supports multiple operating modes:

- Grid-Connected Optimised Mode: Minimises grid draw during peak tariff hours.

- Island Mode: Operates on WHR + Solar + BESS during grid outages.

- Peak Shaving Mode: Uses BESS to offset short-term spikes, reducing demand charges.

- Load Shifting Mode: Aligns high-energy processes with solar availability.

Impact: Field implementations show 18 per cent to 28 per cent reductions in grid imports, 3 per cent to 6 per cent lower specific power costs, improved power quality (fewer nuisance trips), and measurable gains in kiln uptime. By combining solar, WHR, storage and intelligent control, microgrids can transform cement plant energy sourcing into a cleaner, more reliable and more cost-effective system.

How does a flue-gas CO2-to-methanol pilot translate to process efficiencies?

A flue-gas CO2-to-methanol pilot can translate into process efficiencies for both power plants and the cement industry in ways that go beyond just making methanol-it can also improve energy utilisation, plant integration and operational flexibility.

Here’s the breakdown in context:

A. Productive Use of a Waste Stream

- Traditional: Flue gas CO2 is a liability-needs to be vented or captured and stored, consuming energy without direct revenue.

- With CO2-to-Methanol: CO2 becomes a feedstock for a value-added product (methanol), effectively monetising a waste stream.

- Efficiency Link: This improves the overall resource efficiency of the plant because the carbon in the fuel/raw material is not wasted but transformed into a marketable chemical.

B. Integration with Heat and Power Flows

- The hydrogen for methanol synthesis (via water electrolysis) requires significant electricity, ideally from renewable or low-cost surplus power.

- In power plants: The process can use low-grade waste heat from turbines or economisers to preheat CO2/H2 streams, reducing compression and reaction energy.

- In cement plants: Kiln and clinker cooler waste heat can play the same role, allowing higher overall thermal efficiency without disrupting clinker production.

C. Smoothing Power Plant Load and Improving Capacity Factor

- Electrolysers for H2 production can act as a flexible load:

- Ramp up when grid demand is low or renewable generation is high.

- Ramp down when power demand is high.

- Benefit for TPPs: Reduces the need for inefficient low-load operation and enables steadier turbine efficiency.

Benefit for cement plants: If tied to an on-site WHR + PV/BESS microgrid, it can soak up excess renewable/WHR power during low cement demand periods.

D. Synergy with Flue Gas Conditioning

- The CO2 capture step for methanol production often includes flue gas cleaning (removing SOx, NOx, particulates).

- This upgrades the quality of flue gas, which can reduce corrosion/fouling in downstream WHR boilers, improving plant availability and heat recovery efficiency.

E. Reduction in Carbon Intensity

- Power sector: Each tonne of CO2 converted to methanol lowers net emissions, improving compliance with carbon pricing or emission norms.

- Cement sector: Reduces CO2 intensity per tonne of clinker by diverting a portion of process emissions into methanol synthesis.

F. Methanol as a Circular Energy Carrier

The methanol produced can be:

- Sold as a chemical feedstock or marine fuel.

- Used internally in dual-fuel boilers/turbines for backup power.

This creates an energy loop-CO2 captured from flue gas ? methanol ? reconverted to energy when needed, improving energy storage and fuel flexibility.

Can biomass co-firing methods from power plants be customised for cement kilns?

Yes-adaptation is practical, with kiln-specific care:

Transferable learnings from utility co-firing

- Feedstock prep: Size reduction, torrefaction/pelletising, moisture control ? stable feeding through calciner/kiln burners.

- Metering and pneumatics: Proven dosing/air-assist systems maintain steady thermal input and flame shape.

- Chlorine/alkali management: Power-plant protocols for fuel qualification apply directly; in cement, they also protect clinker quality and rings.

- Cement-specific customisations

- Burner tuning: Biomass raises volatiles and lowers flame temperature; adjust primary/secondary air, swirl, momentum to avoid over-penetration or CO spikes.

- Ash chemistry: Track K2O/Na2O/Cl and P2O5 to manage coating and alite formation; limit certain agri residues unless pre-leached or blended.

- Where to fire: Higher substitution is often easier in the calciner than main burner; start 10 per cent to 20 per cent TSR in calciner, step up with monitoring.

- Outcomes: 15 per cent to 35 per cent thermal substitution is realistic with prepared biomass; 1 per cent to 4 per cent specific heat consumption (SHC) reduction from improved combustion stability and moisture trimming.

How does CFD modelling optimise combustion for lower fuel use and emissions?

Computational Fluid Dynamics (CFD) has emerged as an indispensable tool for optimising energy efficiency, combustion stability, and emissions control in cement manufacturing. By simulating the three-dimensional flow dynamics and combustion chemistry inside the kiln, calciner, tertiary air ducts, and burners, CFD provides a deep, visual understanding of how gases, fuels and solids interact. These insights enable targeted design improvements and operational fine-tuning, ultimately reducing energy consumption and extending equipment life.

Design and operational applications. CFD modelling allows engineers to evaluate and optimise critical parameters including:

- Burner Quarles and Jet Geometry: Adjusting jet angles, swirl intensity, and momentum ratios for ideal flame characteristics.

- Airflow Distribution: Balancing secondary and tertiary air splits to match process demand.

- Calciner Staging: Sequencing combustion zones to maximise calcination efficiency.

- SNCR/AFR Injection Points: Locating selective non-catalytic reduction systems and alternative fuel inlets for optimal mixing and burnout.

Efficiency and performance levers are identified through CFD

- Burner Optimisation: Tailoring swirl and jet momentum to create a narrower, elongated flame enhances heat transfer to the kiln bed, delivering a 0.5 per cent to 2 per cent reduction in specific heat consumption (SHC).

- Optimised Calciner Staging: Achieving complete calcination at reduced excess air levels cuts NO emissions by 15 per cent to 30 per cent while avoiding the energy penalties of over-firing.

- Hot-Spot Mitigation: Detecting and eliminating localised high-temperature zones prevents ring formation and coating build-ups, extending refractory life and improving uptime-a significant indirect energy saving.

Strategic AFR Placement: Injecting late-volatile alternative fuels in zones with the right oxygen and temperature balance avoids CO spikes and unburnt fuel losses.

The power of CFD lies not only in simulation but also in validation and integration. Best practice involves confirming model predictions through on-site measurements, including kiln hood and calciner thermography, CO/NOx traverses, and clinker microscopy. Once validated, these insights can be locked into operations using Advanced Process Control (APC) systems, ensuring consistent, long-term efficiency gains.

What role will hydrogen technologies play in decarbonising heavy industries?

Near-term actions (0-5 Years)

- Hydrogen Enrichment of Burners (5 per cent to 20 per cent): Enhance flame stability and precision, enabling higher biomass and alternative fuel (AFR) substitution without incurring CO emissions penalties.

- Green Oxygen Integration: Use oxygen generated from electrolysers to reduce excess air requirements and achieve better stoichiometric control, lowering NOx formation.

- Power-to-Heat Applications – Deploy electro-boilers and electric dryers for plant auxiliaries in solar-rich regions, freeing up fossil-fuel-derived heat for the kiln.

- Medium-term actions (5-10 Years)

- Hydrogen-Ready Burners: Install kiln and calciner burners designed for high hydrogen blends, with ammonia used as a hydrogen carrier and cracked near the point of use.

- E-Fuels Co-Firing: Incorporate e-methanol or e-syngas to provide dispatchable, low-carbon thermal energy.

How are ash or waste-heat recovery (WHR) technologies from power plants applicable to cement production?

Ash utilisation

- Fly Ash in Blended Cements (PPC/PSC): Substituting 25 per cent to 35 per cent clinker with fly ash significantly reduces thermal load and CO2 intensity. Performance depends on Loss on Ignition (LOI), fineness, and phase composition; selectively harvested dry-silo ash offers the most consistent quality.

- Bottom Ash / Pond Ash: Usable in certain

products after classification and grinding, though attention is needed to control unburnt carbon and contaminants. - FGD Gypsum: Flue Gas Desulphurisation gypsum from power plants provides a dependable alternative to natural gypsum for setting regulation.

Waste heat and power integration

• Cement WHR Systems: Using AQC/SP boilers with steam turbines or Organic Rankine Cycle (ORC) units typically recovers 20-35 kWh/t clinker. Best practice involves applying utility pinch-analysis learnings, controlling fouling,

and optimising condenser pressure for uptime and efficiency.

• Cross-Industry Synergies: Co-location with power plants enables use of their low-grade heat (or CO2 capture waste heat) for pre-drying alternative fuels or raw mix; conversely, WHR output from cement plants can supply auxiliary loads during grid peak demand.

• Circular Economy Benefits: Combining ash and FGD gypsum utilisation closes the mineral loop, while WHR and low-grade heat recovery close the energy loop-together lowering Specific Heat Consumption (SHC) and Scope 1 and 2 emissions.

A practical 6-step roadmap for cement plants

• Step 1: Energy Mapping and Pinch Analysis: Assess kiln, calciner, mills, and auxiliaries to identify 1 per cent to 3 per cent SHC savings.

• Step 2: CFD and Advanced Process

Control: Optimise burner, calciner, and AFR injection points for improved efficiency and emissions control.

• Step 3: Solar-WHR-BESS Microgrid: Implement process-aware Energy Management Systems to achieve 15 per cent to 20 per cent peak-shaving.

• Step 4: Biomass/AFR Scale-Up: Apply fuel-lab testing protocols to safely reach 20 per cent to 30 per cent Thermal Substitution Rate (TSR) in the calciner first.

• Step 5: CO2-to-X Pilots: Integrate heat

cascade systems and O2 reuse where green power is accessible.

• Step 6: Power-Sector Partnerships: Secure agreements for deep-turndown tariffs, power-quality guarantees, and consistent Class-A fly ash and FGD gypsum supply.

With contribution from Dr Gaurav Richhariya,

Executive R&D (Ash Technology), NTPC Energy Technology and Research Alliance (NETRA), NTPC.

Concrete

Our strategy is to establish reliable local partnerships

Published

10 hours agoon

February 19, 2026By

admin

Jean-Jacques Bois, President, Nanolike, discusses how real-time data is reshaping cement delivery planning and fleet performance.

As cement producers look to extract efficiency gains beyond the plant gate, real-time visibility and data-driven logistics are becoming critical levers of competitiveness. In this interview with Jean-Jacques Bois, President, Nanolike, we discover how the company is helping cement brands optimise delivery planning by digitally connecting RMC silos, improving fleet utilisation and reducing overall logistics costs.

How does SiloConnect enable cement plants to optimise delivery planning and logistics in real time?

In simple terms, SiloConnect is a solution developed to help cement suppliers optimise their logistics by connecting RMC silos in real time, ensuring that the right cement is delivered at the right time and to the right location. The core objective is to provide real-time visibility of silo levels at RMC plants, allowing cement producers to better plan deliveries.

SiloConnect connects all the silos of RMC plants in real time and transmits this data remotely to the logistics teams of cement suppliers. With this information, they can decide when to dispatch trucks, how to prioritise customers, and how to optimise fleet utilisation. The biggest savings we see today are in logistics efficiency. Our customers are able to sell and ship more cement using the same fleet. This is achieved by increasing truck rotation, optimising delivery routes, and ultimately delivering the same volumes at a lower overall logistics cost.

Additionally, SiloConnect is designed as an open platform. It offers multiple connectors that allow data to be transmitted directly to third-party ERP systems. For example, it can integrate seamlessly with SAP or other major ERP platforms, enabling automatic order creation whenever replenishment is required.

How does your non-exclusive sensor design perform in the dusty, high-temperature, and harsh operating conditions typical of cement plants?

Harsh operating conditions such as high temperatures, heavy dust, extreme cold in some regions, and even heavy rainfall are all factored into the product design. These environmental challenges are considered from the very beginning of the development process.

Today, we have thousands of sensors operating reliably across a wide range of geographies, from northern Canada to Latin America, as well as in regions with heavy rainfall and extremely high temperatures, such as southern Europe. This extensive field experience demonstrates that, by design, the SiloConnect solution is highly robust and well-suited for demanding cement plant environments.

Have you initiated any pilot projects in India, and what outcomes do you expect from them?

We are at the very early stages of introducing SiloConnect in India. Recently, we installed our

first sensor at an RMC plant in collaboration with FDC Concrete, marking our initial entry into the Indian market.

In parallel, we are in discussions with a leading cement producer in India to potentially launch a pilot project within the next three months. The goal of these pilots is to demonstrate real-time visibility, logistics optimisation and measurable efficiency gains, paving the way for broader adoption across the industry.

What are your long-term plans and strategic approach for working with Indian cement manufacturers?

For India, our strategy is to establish strong and reliable local partnerships, which will allow us to scale the technology effectively. We believe that on-site service, local presence, and customer support are critical to delivering long-term value to cement producers.

Ideally, our plan is to establish an Indian entity within the next 24 months. This will enable us to serve customers more closely, provide faster support and contribute meaningfully to the digital transformation of logistics and supply chain management in the Indian cement industry.

Economy & Market

Power Build’s Core Gear Series

Published

10 hours agoon

February 19, 2026By

admin

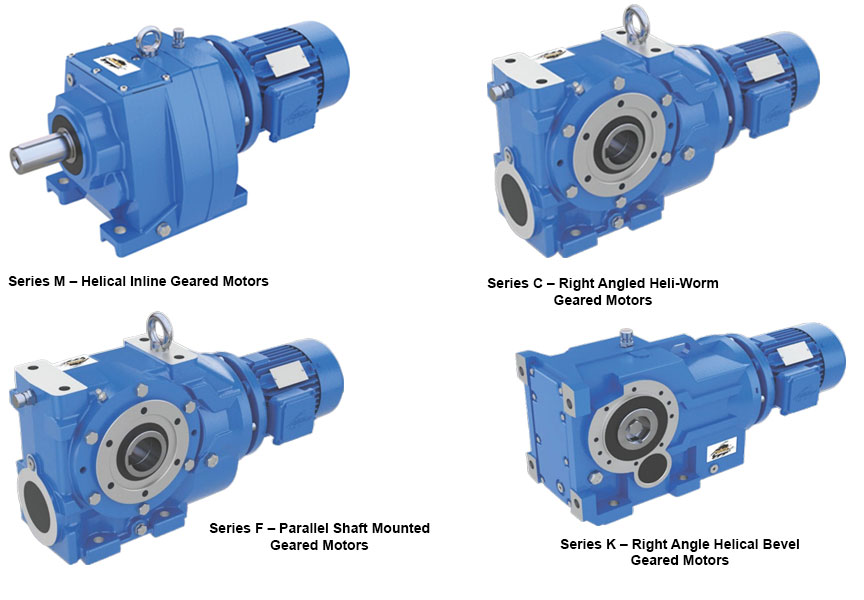

A deep dive into Core Gear Series of products M, C, F and K, by Power Build, and how they represent precision in motion.

At the heart of every high-performance industrial system lies the need for robust, reliable, and efficient power transmission. Power Build answers this need with its flagship geared motor series: M, C, F and K. Each series is meticulously engineered to serve specific operational demands while maintaining the universal promise of durability, efficiency, and performance.

Series M – Helical Inline Geared Motors

Compact and powerful, the Series M delivers exceptional drive solutions for a broad range of applications. With power handling up to 160kW and torque capacity reaching 20,000 Nm, it is the trusted solution for industries requiring quiet operation, high efficiency, and space-saving design. Series M is available with multiple mounting and motor options, making it a versatile choice for manufacturers and OEMs globally.

Series C – Right Angled Heli-Worm Geared Motors

Combining the benefits of helical and worm gearing, the Series C is designed for right-angled power transmission. With gear ratios of up to 16,000:1 and torque capacities of up to 10,000 Nm, this series is optimal for applications demanding precision in compact spaces. Industries looking for a smooth, low-noise operation with maximum torque efficiency rely on Series C for dependable performance.

Series F – Parallel Shaft Mounted Geared Motors

Built for endurance in the most demanding environments, Series F is widely adopted in steel plants, hoists, cranes and heavy-duty conveyors. Offering torque up to 10,000 Nm and high gear ratios up to 20,000:1, this product features an integral torque arm and diverse output configurations to meet industry-specific challenges head-on.

Series K – Right Angle Helical Bevel Geared Motors

For industries seeking high efficiency and torque-heavy performance, Series K is the answer. This right-angled geared motor series delivers torque up to 50,000 Nm, making it a preferred choice in core infrastructure sectors such as cement, power, mining and material handling. Its flexibility in mounting and broad motor options offer engineers the freedom in design and reliability in execution.

Together, these four series reflect Power Build’s commitment to excellence in mechanical power transmission. From compact inline designs to robust right-angle drives, each geared motor is a result of decades of engineering innovation, customer-focused design and field-tested reliability. Whether the requirement is speed control, torque multiplication or space efficiency, Radicon’s Series M, C, F and K stand as trusted powerhouses for global industries.

http://www.powerbuild.in

Call: +919727719344

Concrete

Compliance and growth go hand in h and

Published

10 hours agoon

February 19, 2026By

admin

Pankaj Kejriwal, Whole Time Director and COO, Star Cement, on driving efficiency today and designing sustainability for tomorrow.

In an era where the cement industry is under growing pressure to decarbonise while scaling capacity, Star Cement is charting a pragmatic yet forward-looking path. In this conversation, Pankaj Kejriwal, Whole Time Director and COO, Star Cement, shares how the company is leveraging waste heat recovery, alternative fuels, low-carbon products and clean energy innovations to balance operational efficiency with long-term sustainability.

How has your Lumshnong plant implemented the 24.8 MW Waste Heat Recovery System (WHRS), and what impact has it had on thermal substitution and energy costs?

Earlier, the cost of coal in the Northeast was quite reasonable, but over the past few years, global price increases have also impacted the region. We implemented the WHRS project about five years ago, and it has resulted in significant savings by reducing our overall power costs.

That is why we first installed WHRS in our older kilns, and now it has also been incorporated into our new projects. Going forward, WHRS will be essential for any cement plant. We are also working on utilising the waste gases exiting the WHRS, which are still at around 100 degrees Celsius. To harness this residual heat, we are exploring systems based on the Organic Rankine Cycle, which will allow us to extract additional power from the same process.

With the launch of Star Smart Building Solutions and AAC blocks, how are you positioning yourself in the low-carbon construction materials segment?

We are actively working on low-carbon cement products and are currently evaluating LC3 cement. The introduction of autoclaved aerated concrete (AAC) blocks provided us with an effective entry into the consumer-facing segment of the industry. Since we already share a strong dealer network across products, this segment fits well into our overall strategy.

This move is clearly supporting our transition towards products with lower carbon intensity and aligns with our broader sustainability roadmap.

With a diverse product portfolio, what are the key USPs that enable you to support India’s ongoing infrastructure projects across sectors?

Cement requirements vary depending on application. There is OPC, PPC and PSC cement, and each serves different infrastructure needs. We manufacture blended cements as well, which allows us to supply products according to specific project requirements.

For instance, hydroelectric projects, including those with NHPC, have their own technical norms, which we are able to meet. From individual home builders to road infrastructure, dam projects, and regions with heavy monsoon exposure, where weather-shield cement is required, we are equipped to serve all segments. Our ability to tailor cement solutions across diverse climatic and infrastructure conditions is a key strength.

How are you managing biomass usage, circularity, and waste reduction across

your operations?

The Northeast has been fortunate in terms of biomass availability, particularly bamboo. Earlier, much of this bamboo was supplied to paper plants, but many of those facilities have since shut down. As a result, large quantities of bamboo biomass are now available, which we utilise in our thermal power plants, achieving a Thermal Substitution Rate (TSR) of nearly 60 per cent.

We have also started using bamboo as a fuel in our cement kilns, where the TSR is currently around 10 per cent to 12 per cent and is expected to increase further. From a circularity perspective, we extensively use fly ash, which allows us to reuse a major industrial waste product. Additionally, waste generated from HDPE bags is now being processed through our alternative fuel and raw material (AFR) systems. These initiatives collectively support our circular economy objectives.

As Star Cement expands, what are the key logistical and raw material challenges you face in scaling operations?

Fly ash availability in the Northeast is a constraint, as there are no major thermal power plants in the region. We currently source fly ash from Bihar and West Bengal, which adds significant logistics costs. However, supportive railway policies have helped us manage this challenge effectively.

Beyond the Northeast, we are also expanding into other regions, including the western region, to cater to northern markets. We have secured limestone mines through auctions and are now in the process of identifying and securing other critical raw material resources to support this expansion.

With increasing carbon regulations alongside capacity expansion, how do you balance compliance while sustaining growth?

Compliance and growth go hand in hand for us. On the product side, we are working on LC3 cement and other low-carbon formulations. Within our existing product portfolio, we are optimising operations by increasing the use of green fuels and improving energy efficiency to reduce our carbon footprint.

We are also optimising thermal energy consumption and reducing electrical power usage. Notably, we are the first cement company in the Northeast to deploy EV tippers at scale for limestone transportation from mines to plants. Additionally, we have installed belt conveyors for limestone transfer, which further reduces emissions. All these initiatives together help us achieve regulatory compliance while supporting expansion.

Looking ahead to 2030 and 2050, what are the key innovation and sustainability priorities for Star Cement?

Across the cement industry, carbon capture is emerging as a major focus area, and we are also planning to work actively in this space. In parallel, we see strong potential in green hydrogen and are investing in solar power plants to support this transition.

With the rapid adoption of solar energy, power costs have reduced dramatically – from 10–12 per unit to around2.5 per unit. This reduction will enable the production of green hydrogen at scale. Once available, green hydrogen can be used for electricity generation, to power EV fleets, and even as a fuel in cement kilns.

Burning green hydrogen produces only water and oxygen, eliminating carbon emissions from that part of the process. While process-related CO2 emissions from limestone calcination remain a challenge, carbon capture technologies will help address this. Ultimately, while becoming a carbon-negative industry is challenging, it is a goal we must continue to work towards.

Our strategy is to establish reliable local partnerships

Power Build’s Core Gear Series

Compliance and growth go hand in h and

Turning Downtime into Actionable Intelligence

FORNNAX Appoints Dieter Jerschl as Sales Partner for Central Europe

Our strategy is to establish reliable local partnerships

Power Build’s Core Gear Series

Compliance and growth go hand in h and

Turning Downtime into Actionable Intelligence