Product development

Mining projects worth Rs 41k cr stalled

Published

8 years agoon

By

admin

The mines department had signed 17 MoUs, with a proposed investment worth Rs 45,532 crore, during the Resurgent Rajasthan summit in November 2015. However, till April 2017, only Rs 4,395.27 crore (or 9.65 per cent) investment had materialised. The government had hailed the summit for bringing in much needed private investment. Industry players, however, said that hurdles remain, especially land acquisition, as stringent rules under the Land Acquisition Act 2013 make it a tough proposition. Among the big-ticket investors were Ambuja Cement, Jindal Saw, Reliance Cement, Steel Authority of India Ltd, Rashtriya Ispat Nigam Ltd and Ultratech Cement. Now, many of the proposals have been put on hold or entirely dropped because of delay in land acquisition, as land is either charagah (pasture) or forest land.

Arihant to invest Rs 4k cr on housing projects

Real estate firm Arihant Superstructures will invest about Rs 4,000 crore over the next six years on construction of its 15 ongoing projects in Navi Mumbai and Jodhpur, a top company official said. The Mumbai-based developer has completed around 2.5 million sq ft area across nine projects.

‘We are currently developing 15 projects in Navi Mumbai and Jodhpur comprising 12.9 million sq ft area,’ the company’s Chairman and Managing Director Ashok Chhajer told. The company is developing around 12,000 units in these projects. ‘We focus on affordable housing. Out of our total portfolio, 66 per cent is low-cost homes in a price range of Rs 20-50 lakh,’ he said.

Asked about investment in the ongoing projects, Chhajer said the land cost is already paid while Rs 4,000 crore would be required to complete construction of these 15 projects. The construction cost would be funded through internal accruals, bank loans and advances from customers. Arihant is expecting Rs 6,000 crore revenues from these 15 projects over the next six years. Out of 15 projects, around 10 are in Navi Mumbai and rest in Jodhpur.

Chhajer said the company is concentrating on project execution and delivered about 1,100 flats covering 1 million sq ft area during last fiscal. This year, the company is targeting delivery of 1.5 million sq ft. On sales bookings, he said they have improved and the company sold 580 units worth about Rs 200 crore in the first half of this fiscal. Arihant is also looking to develop more projects in Navi Mumbai and Mumbai metropolitan region. The company achieved a turnover of Rs 186 crore last fiscal and is expecting about 25 per cent growth in 2017-18.

JDA to allot 1,396 affordable houses in Nov

The Jaipur Development Authority (JDA) is all set to allot 1,396 houses for economic weaker section (EWS), lower income group (LIG) and middle income group (MIG) categories in November. The houses have been constructed by private developers under Mukhyamantri Awas Yojna and will be allotted on affordable housing rates fixed by the state government. Maximum number of houses have been developed in zone-14. Rest of the houses are in zones 7, 9, 10, 11 and 12.

‘In the financial year 2017-2018, JDA’s target was to construct 20,000 houses for EWS and LIG sections. The civic body, so far, has issued lease deeds to 12,790 house owners falling under these categories,’ a JDA official said. In two-and-a-half years, JDA has issued 35,300 lease deeds. Out of them, 11,000 EWS and LIG houses were developed in JDA schemes. While the remaining houses were earmarked in private colonies.

The Urban Development and Housing (UDH) department has proposed several amendments in the affordable housing policy to motivate developers to construct houses for EWS and LIG on both private and government land. To achieve the target of constructing 10 lakh houses till 2018 under the Housing For All scheme, the state government will now focus on providing free land for affordable housing projects on PPP mode.

Vedanta plans Rs 10k cr investment in Jharkhand

Vedanta Resources Chief Anil Agarwal has lined up a Rs 10,000 crore investment plan for Jharkhand. This includes an iron ore mining project and an integrated steel plant. Agarwal, who hails from the region, said the project will mark his entry into steel. It will also complete Vedanta’s metals portfolio that includes aluminium, zinc, copper and lead.

‘We will invest nearly Rs 10,000 crore in Jharkhand. The state has immense potential to develop and the Chief Minister, Raghubar Das, is leading the way,’ Agarwal told. Sharing his plans for the state, Agarwal said India, and Jharkhand in particular, is endowed with some of the best quality iron ore reserves. ‘We have to develop these resources with due forest and environment safeguards. This way we create jobs within the country instead of using up precious foreign exchange for imports of natural resources,’ he added.

‘We want to set up a bigger steel plant in Jharkhand but will start with an integrated plant of 1million tonne hot metal capacity at Manoharpur,’ Agarwal said. For this, a memorandum of understanding had been signed with the state government in May 2016. At the initial stages, investment on the projects is likely to be around Rs 2,500 crore, a company official said. Out of 437 acres required for the steel plant, some 110 acres have already been purchased. Also, the government is in the process of allotting 41 acres of land it owns.

Cement prices to rise following petcoke ban

Cement prices in northern states of India are expected to rise on the back of rising costs brought about by a ban on the use of petcoke in the Delhi NCR region from November 1, according to India Ratings and Research. Petcoke is a key raw material that goes into the making of cement.

‘Cement players in the northern region particularly from Rajasthan (where most of the clinker plants are situated) will have to use either domestic coal or imported coal from 1 November 2017. This will result in an increase in power and fuel cost per tonne per bag by Rs 8-10,’ Ind-Ra said in a release. Cement producers are likely to pass the hike in costs to the final consumer, leading to an increase in cement price.

According to Environmental Pollution (prevention and control) Authority’s clarification dated 27 October 2017, such ban will be applicable only in those districts of Uttar Pradesh, Haryana and Rajasthan which fall under NCR; however if the state governments fail to issue a similar notification, then the ban will automatically be applied to the whole state, impacting all cement manufacturers. Industries using pet coke and furnace oil will have to comply by the norms issued by Central Pollution Control Board latest by 31 December 2017.

Cement firm to recycle non-bio waste

In a novel attempt to clear space at Perambalur municipality’s (Tamil Nadu) dump yard, the civic body has started sending a portion of the segregated waste to a private cement firm in Ariyalur for use as fuel in the boilers. Reusable non-biodegradable waste collected from municipality limits would be packed and sent to the factory in order to make space in the dump yard and also prevent the waste from serving as breeding ground for mosquitoes.

According to the municipality officials, about two acres of the dump yard situated within city outskirts has been accommodating 30 tonnes of waste, including 20 tonnes of recyclable waste, generated by the city a day. The municipality, with 21 wards, has roped in a private cement manufacturing plant in Ariyalur to use the waste dumped in the yard for being used as a fuel for the boilers in the industry.

‘Ultratech would move the required waste such as clothes and leather sourced from the municipality’s dumpyard to their facility once a week. By doing so, we can free space in the yard which could be well used for making compost from the organic waste collected,’ R Murali, Commissioner, Perambalur Municipality, said.

A team to monitor ‘slow’ smart city projects

Criticism regarding slow progress of work in Smart Cities Mission projects has prompted the Union government to monitor them. A team of Union government officials will keep a watch on the projects and an official will visit the city soon to check the ground reality.

The Pune Smart City Development Corporation Limited (PSCDCL) and Pune Municipal Corporation (PMC) have been tasked with the responsibility of executing the projects. Altogether 14 projects were launched in the city in 2016 in presence of Prime Minister Narendra Modi. ‘The team will review projects that are being named as smart cities project. They will visit the sites where work under the mission are being carried out or are being proposed to be carried out. Reports will be published at regular intervals,’ said sources. They said that the team was expected to visit the city this month. Along with elected members of opposition parties, activists and citizens too had raised doubts over the projects under smart cities mission. Even leaders of ruling BJP had expressed displeasure over the delay in execution of the work. Two smart cities projects were launched in the city in October. Expressing disappointment over slow pace of work under the smart cities mission, guardian minister Girish Bapat had urged the civic body to expedite the projects. Sources said the pace of projects had slowed down and like metro rail, ring road and development plan projects, they had failed to maintain the momentum.

Aundh, Baner and Balewadi areas have been identified for projects under the Smart City Mission. Some pan-city initiatives have been planned to cover bigger areas. Pune was among the first few cities to have been selected under the mission.

BRO to issue fresh tenders for NS bridge

After wasting nearly eight years, the Border Roads Organisation (BRO) is now mulling to issue fresh tenders for the completion of reconstruction work of Nand Singh bridge (NS bridge) on Srinagar-Muzaffarabad Highway near Uri Town of North Kashmir’s Baramulla district.

A BRO official said with a total project cost of Rs 200.27 lakh, the tender was allotted to Lokpaul Fabrication Construction but non-compliance from the company has forced them to cancel their allotment and issue fresh tenders. ‘The company did not follow the design which was approved by the BRO,’ he said.

The locals of the area said a tussle between the construction company and the BRO has delayed the completion of the Bridge and alleged that Government was acting as a mute spectator even as people continue to face extreme hardships.

‘In last eight-nine years, we have only seen workers welding the iron slabs. It is shame on part of Government that it has failed to provide us a proper connecting link. It pays no heed to our problems,’ he said.

The locals said the bridge was declared unsafe for vehicular movement after it was damaged in year 2005 earthquake. They said after the bridge was damaged, several villages of Uri remained cut off for a while until BRO constructed a makeshift bridge at its place. ‘The makeshift structure got damaged, during the flash floods of 2014 and people are putting their lives at risk by using it,’ Mushtaq Ahmad, a local said, adding the construction company who was given the job to carry out the reconstruction work abandoned the work only after few months.

Mohali airport road foundation to be re-laid by Dec-end

The Greater Mohali Area Development Authority (Gmada) has dug up the airport road at four places to relay the foundation and make it motorable. Gmada Chief Administrator Ravi Bhagat said the repair work will be completed by December end before onset of winters enabling vehicular movement on the road. The work was expedited after Punjab chief minister Amarinder Singh constituted a technical committee headed by Lieutenant General (Retd.) BS Dhaliwal, chief engineer national highway PWD (B&R) AK Singla, chief engineer Gmada Sunil Kansal and principal scientist and head of flexible pavements division, Central Road Research Institute (CRRI) Manoj Kumar Shukla who recommended that the road must be dug up to relay the foundation instead of re-carpeting of it on surface.

Jammu smart city project to start by Dec

The work on Jammu smart city project is likely to start by December. Jammu Municipal Corporation Commissioner Ramesh Kumar said the first installment of Rs 200 crore of Rs 3,600 crore project is scheduled to be released next month by the Centre.

‘The ground work for Smart City project is in final stages and before December the first installment of Rs 200 crore will be released by Government of India,’ he told the Excelsior.

Jammu and Srinagar have been selected in the list of the Smart cities to be developed across the country and is one of the flagship programmes of the Modi Government. The project is aimed to give a better experience in the cities with host of measures and schemes. Ramesh, who had recently taken over the charge, though agrees to it’s challenging nature.

‘The smart City is to be created at the same site within a given and limited space. So managing thickly populated cluster, haphazardously raised and ill planned areas will be a tough task,’ he said. NC MLA and provincial president had criticised the Government for creating Smart city at the same place.

Economy & Market

Power Build’s Core Gear Series

Published

11 hours agoon

February 19, 2026By

admin

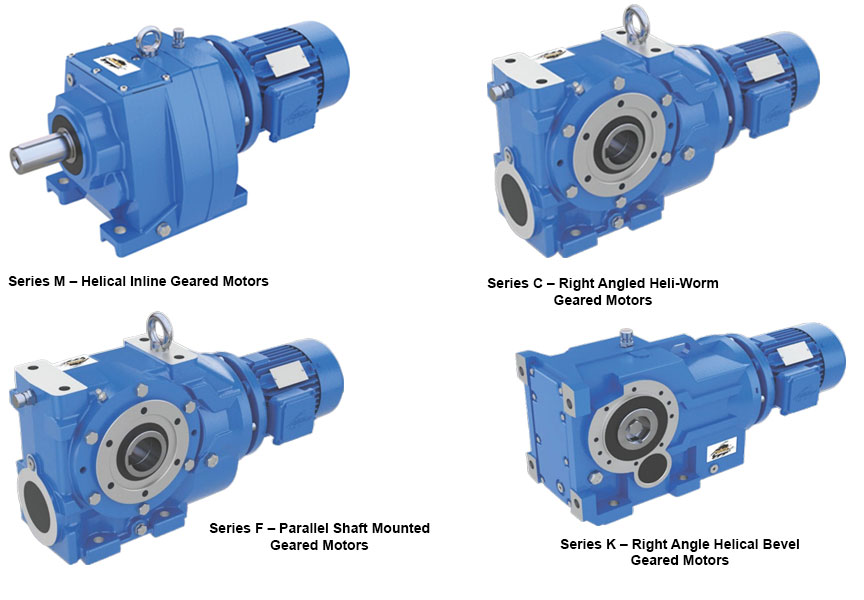

A deep dive into Core Gear Series of products M, C, F and K, by Power Build, and how they represent precision in motion.

At the heart of every high-performance industrial system lies the need for robust, reliable, and efficient power transmission. Power Build answers this need with its flagship geared motor series: M, C, F and K. Each series is meticulously engineered to serve specific operational demands while maintaining the universal promise of durability, efficiency, and performance.

Series M – Helical Inline Geared Motors

Compact and powerful, the Series M delivers exceptional drive solutions for a broad range of applications. With power handling up to 160kW and torque capacity reaching 20,000 Nm, it is the trusted solution for industries requiring quiet operation, high efficiency, and space-saving design. Series M is available with multiple mounting and motor options, making it a versatile choice for manufacturers and OEMs globally.

Series C – Right Angled Heli-Worm Geared Motors

Combining the benefits of helical and worm gearing, the Series C is designed for right-angled power transmission. With gear ratios of up to 16,000:1 and torque capacities of up to 10,000 Nm, this series is optimal for applications demanding precision in compact spaces. Industries looking for a smooth, low-noise operation with maximum torque efficiency rely on Series C for dependable performance.

Series F – Parallel Shaft Mounted Geared Motors

Built for endurance in the most demanding environments, Series F is widely adopted in steel plants, hoists, cranes and heavy-duty conveyors. Offering torque up to 10,000 Nm and high gear ratios up to 20,000:1, this product features an integral torque arm and diverse output configurations to meet industry-specific challenges head-on.

Series K – Right Angle Helical Bevel Geared Motors

For industries seeking high efficiency and torque-heavy performance, Series K is the answer. This right-angled geared motor series delivers torque up to 50,000 Nm, making it a preferred choice in core infrastructure sectors such as cement, power, mining and material handling. Its flexibility in mounting and broad motor options offer engineers the freedom in design and reliability in execution.

Together, these four series reflect Power Build’s commitment to excellence in mechanical power transmission. From compact inline designs to robust right-angle drives, each geared motor is a result of decades of engineering innovation, customer-focused design and field-tested reliability. Whether the requirement is speed control, torque multiplication or space efficiency, Radicon’s Series M, C, F and K stand as trusted powerhouses for global industries.

http://www.powerbuild.in

Call: +919727719344

Economy & Market

Conveyor belts are a vital link in the supply chain

Published

8 months agoon

June 16, 2025By

admin

Kamlesh Jain, Managing Director, Elastocon, discusses how the brand delivers high-performance, customised conveyor belt solutions for demanding industries like cement, mining, and logistics, while embracing innovation, automation, and sustainability.

In today’s rapidly evolving industrial landscape, efficient material handling isn’t just a necessity—it’s a competitive advantage. As industries such as mining, cement, steel and logistics push for higher productivity, automation, and sustainability, the humble conveyor belt has taken on a mission-critical role. In this exclusive interview, Kamlesh Jain, Managing Director, Elastocon, discusses how the company is innovating for tougher terrains, smarter systems and a greener tomorrow.

Brief us about your company – in terms of its offerings, manufacturing facilities, and the key end-user industries it serves.

Elastocon, a flagship brand of the Royal Group, is a trusted name in the conveyor belt manufacturing industry. Under the brand name ELASTOCON, the company produces both open-end and endless belts, offering tailor-made solutions to some of the most demanding sectors such as cement, steel, power, mining, fertiliser, and logistics. Every belt is meticulously engineered—from fabric selection to material composition—to ensure optimal performance in tough working conditions. With advanced manufacturing facilities and strict quality protocols, Elastocon continues to deliver high-performance conveyor solutions designed for durability, safety, and efficiency.

How is the group addressing the needs for efficient material handling?

Efficient material handling is the backbone of any industrial operation. At Elastocon, our engineering philosophy revolves around creating belts that deliver consistent performance, long operational life, and minimal maintenance. We focus on key performance parameters such as tensile strength, abrasion resistance, tear strength, and low elongation at working tension. Our belts are designed to offer superior bonding between plies and covers, which directly impacts their life and reliability. We also support clients

with maintenance manuals and technical advice, helping them improve their system’s productivity and reduce downtime.

How critical are conveyor belts in ensuring seamless material handling?

Conveyor belts are a vital link in the supply chain across industries. In sectors like mining, cement, steel, and logistics, they facilitate the efficient movement of materials and help maintain uninterrupted production flows. At Elastocon, we recognise the crucial role of belts in minimising breakdowns and increasing plant uptime. Our belts are built to endure abrasive, high-temperature, or high-load environments. We also advocate proper system maintenance, including correct belt storage, jointing, roller alignment, and idler checks, to ensure smooth and centered belt movement, reducing operational interruptions.

What are the key market and demand drivers for the conveyor belt industry?

The growth of the conveyor belt industry is closely tied to infrastructure development, increased automation, and the push for higher operational efficiency. As industries strive to reduce labor dependency and improve productivity, there is a growing demand for advanced material handling systems. Customers today seek not just reliability, but also cost-effectiveness and technical superiority in the belts they choose. Enhanced product aesthetics and innovation in design are also becoming significant differentiators. These trends are pushing manufacturers to evolve continuously, and Elastocon is leading the way with customer-centric product development.

How does Elastocon address the diverse and evolving requirements of these sectors?

Our strength lies in offering a broad and technically advanced product portfolio that serves various industries. For general-purpose applications, our M24 and DINX/W grade belts offer excellent abrasion resistance, especially for RMHS and cement plants. For high-temperature operations, we provide HR and SHR T2 grade belts, as well as our flagship PYROCON and PYROKING belts, which can withstand extreme heat—up to 250°C continuous and even 400°C peak—thanks to advanced EPM polymers.

We also cater to sectors with specialised needs. For fire-prone environments like underground mining, we offer fire-resistant belts certified to IS 1891 Part V, ISO 340, and MSHA standards. Our OR-grade belts are designed for oil and chemical resistance, making them ideal for fertiliser and chemical industries. In high-moisture applications like food and agriculture, our MR-grade belts ensure optimal performance. This diverse range enables us to meet customer-specific challenges with precision and efficiency.

What core advantages does Elastocon offer that differentiate it from competitors?

Elastocon stands out due to its deep commitment to quality, innovation, and customer satisfaction. Every belt is customised to the client’s requirements, supported by a strong R&D foundation that keeps us aligned with global standards and trends. Our customer support doesn’t end at product delivery—we provide ongoing technical assistance and after-sales service that help clients maximise the value of their investments. Moreover, our focus on compliance and certifications ensures our belts meet stringent national and international safety and performance standards, giving customers added confidence.

How is Elastocon gearing up to meet its customers’ evolving needs?

We are conscious of the shift towards greener and smarter manufacturing practices. Elastocon is embracing sustainability by incorporating eco-friendly materials and energy-efficient manufacturing techniques. In parallel, we are developing belts that seamlessly integrate with automated systems and smart industrial platforms. Our vision is to make our products not just high-performing but also future-ready—aligned with global sustainability goals and compatible with emerging technologies in industrial automation and predictive maintenance.

What trends do you foresee shaping the future of the conveyor belt industry?

The conveyor belt industry is undergoing a significant transformation. As Industry 4.0 principles gain traction, we expect to see widespread adoption of smart belts equipped with sensors for real-time monitoring, diagnostics, and predictive maintenance. The demand for recyclable materials and sustainable designs will continue to grow. Furthermore, industry-specific customisation will increasingly replace standardisation, and belts will be expected to do more than just transport material—they will be integrated into intelligent production systems. Elastocon is already investing in these future-focused areas to stay ahead of the curve.

Advertising or branding is never about driving sales. It’s about creating brand awareness and recall. It’s about conveying the core values of your brand to your consumers. In this context, why is branding important for cement companies? As far as the customers are concerned cement is simply cement. It is precisely for this reason that branding, marketing and advertising of cement becomes crucial. Since the customer is unable to differentiate between the shades of grey, the onus of creating this awareness is carried by the brands. That explains the heavy marketing budgets, celebrity-centric commercials, emotion-invoking taglines and campaigns enunciating the many benefits of their offerings.

Marketing strategies of cement companies have undergone gradual transformation owing to the change in consumer behaviour. While TV commercials are high on humour and emotions to establish a fast connect with the customer, social media campaigns are focussed more on capturing the consumer’s attention in an over-crowded virtual world. Branding for cement companies has become a holistic growth strategy with quantifiable results. This has made brands opt for a mix package of traditional and new-age tools, such as social media. However, the hero of every marketing communication is the message, which encapsulates the unique selling points of the product. That after all is crux of the matter here.

While cement companies are effectively using marketing tools to reach out to the consumers, they need to strengthen the four Cs of the branding process – Consumer, Cost, Communication and Convenience. Putting up the right message, at the right time and at the right place for the right kind of customer demographic is of utmost importance in the long run. It is precisely for this reason that regional players are likely to have an upper hand as they rely on local language and cultural references to drive home the point. But modern marketing and branding domain is exponentially growing and it would be an interesting exercise to tabulate and analyse its impact on branding for cement.

Our strategy is to establish reliable local partnerships

Power Build’s Core Gear Series

Compliance and growth go hand in h and

Turning Downtime into Actionable Intelligence

FORNNAX Appoints Dieter Jerschl as Sales Partner for Central Europe

Our strategy is to establish reliable local partnerships

Power Build’s Core Gear Series

Compliance and growth go hand in h and

Turning Downtime into Actionable Intelligence