Product Development

Co-processing of alternate fuels

Published

4 years agoon

By

admin

The absence of necessary infrastructure to support co-processing is one of the main reasons of its slow growth in India. There is thus, an urgent need for stakeholders to come together and evolve a national strategy and a time bound programme for building up the infrastructure, writes SP Deolalkar.

The Indian cement industry, Number Two in the world, is modern technology-wise, and efficient in terms of energy consumption. It is consciously taking steps to bring down CO2 emissions. As a part of this effort, India has taken up co-processing of Alternate Fuels (AF) but the overall rate of substitution is very low, just about one per cent. Technologies for using various types of AFs are available and have been successfully used elsewhere with substitution rates as high 30 – 40 per cent in European countries. Absence of necessary infrastructure to support co processing is the main reason of its slow growth in India.

Volume of AFs required

Installed capacity for and actual production of cement in India is 330 and 250 mtpa respectively. About 75 per cent cements produced are blended cements. With a clinker/cement ratio of ~ 0.72, clinker production would be ~ 180 mtpa requiring 38 – 40 mtpa of raw coal. If only ten per cent of it is replaced by AF, requirement of AF would be say 3.5 – 4 mtpa. Thus, there is tremendous scope for development of AFs as a viable industry in itself. Various aspects of co-processing AFs have been brought out in the author’s book ‘Designing Green Cement Plants in Section 4, devoted to AFR.

Need for infrastructure

The simple reason for the need for infrastructure is to create an environment where wastes with potential as fuels (AFs) would be continuously available to cement companies preferably in ready to use form. Incidentally, using coal also requires infrastructure and processing to be able to fire it in kilns and calciners. Historically, cement companies have taken on themselves this responsibility.

In contrast to coal, AFs come from a vast number of sources, are spread over a wide territory and differ greatly in properties and availability. Identified as wastes till now, it is necessary to begin at the beginning when planning to convert them into fuels and using them. Processing required to be done varies greatly from one type of AF to the other.

Co-processing replaces fossil fuel by say, a maximum 40 per cent. A cement plant is therefore required to process two types of fuels- sometimes three – if it is required to use two types of AFs as their continuous availability is not assured as of now. Hence investments in machinery and buildings for processing AFs are considered risky. For these reasons, cement companies would prefer buying the AF that can be delivered on their doorstep in ready to use form. This in turn implies outsourcing of this activity which is a new feature. Creating such supporting facilities means creating infrastructure. An appropriate example of an infrastructure created to meet the needs of the society is ‘AMUL’.

Infrastructure required for AFs

The concept of using wastes on a large scale itself being new, there is not much information on their properties, sources and locations. Infrastructure would therefore comprise of:

- Compilation of data in the form of a directory of wastes and potential AFs among them.

- Testing the more promising among them for determining various aspects of burning them as fuels. Pilot plant tests on the selected AFs.

- Setting up agencies which would do handling and processing of AFs and would supply them on a commercial scale to cement (or any other) industry continuously.

Directory of wastes and their potential

The first step in the build-up of infrastructure would be to collect categorical data on wastes that could be AFs. Such data would classify wastes and other non conventional sources of fuel according to their properties, heat value, sources, locations, availability and volume/ quantity.

Such data supplemented by maps showing locations would be very useful to potential users.

Refer to the map which is similar to maps of Geological Survey of India for mineral wealth of the country.

Often this is the starting point for location of a green field cement plant. Such data should be collected on a national level and should be available for all industries and for uses other than burning also.

Research on wastes as fuels

The next step on a national scale would be to have a fuel research institute that would carry out detailed research on every aspect of combustion of likely AFs such as products of combustion, gases emitted and ashes produced. In making cement, ashes enter clinker produced. Some wastes give away harmful compounds like NOx , dioxins, heavy metals. It is important to know about them before beginning to use them on a large scale. The Central Fuel Research Institute can be one such institute and should play an important role. If not equipped now, it should be strengthened and expanded by opening branches to serve the country as a whole.

Pilot plant tests

The next step in use of AFs would be to carry out pilot plant tests in a set up that simulates actual operating conditions. All aspects of co-processing that would influence regular operation and quality of product and emissions into the environment should be carefully observed and monitored. The tests would bring out aspects like efficiency of combustion, and the extent to which AF could replace fossil fuel. They would be the basis for designing of the system for co-processing in a real plant.

Such pilot plant tests assume great significance as their results would be the basis for approval and permission for co-processing on commercial scale continuously, by government agencies like Bureau of Indian Standards and Pollution Control Boards who would be invited to witness the tests. There are only a limited number of institutions that are equipped to carry out such pilot plant tests like for example NCCBM and CRS of ACC.

Since the requirements of pilot tests would increase with number of users and types of AFs, facilities in these institutes should be made available to other cement companies, say at cost. It should not be necessary to invent the wheel every time. Tests carried out on a given type of AF, if successful should be acceptable for that type as such.

Infrastructure for bringing AFs in ready to use form

This would be regional and product-wise. It has two main constituents:

- Collection and transport of wastes to the processor and transport of processed AF to users like cement companies.

- Processors of wastes who receive, store, blend and process wastes as per the requirements of users.

Transport can be within a state or interstate. Transporters may specialise in transporting specific types of AFs like, sludges, hazardous wastes, MSW, etc. That is because the transporting vehicles would have to be designed to suit wastes and AFs carried. Wastes occur all over the country but certain types of waste are predominant in specific regions. Their volume could also be large enough. In that case there can be more than one Intermediate Service Provider (ISP) or processor for one type of AF. It can be the other way round also; depending on relative locations of, processors and users, supply of processed AF can be within state or interstate. A processor may prefer to deal with one or say up to three types of wastes as different wastes require different facilities for handling, storing and processing for turning them into ready for use AFs.

A very important aspect of service to be rendered as supplier of AFs is the control on quality. It begins at the origin. Only those wastes which conform to the representative character established in research stations would be lifted. At the processor’s premises, it will be necessary to blend wastes as they may be from different sources from time to time or would differ in quality from same source to ensure uniformity of quality.

The processor has therefore to equip himself with necessary testing equipment to satisfy himself and his clients about the quality. He should have equipment that would do pre blending.

If the processor is thus equipped with facilities for testing at all stages of processing, the users do not have to duplicate them in their respective factory premises.

Processors will maintain stocks of wastes for processing and also stocks of processed AFs to be able to maintain continuity of supply of AFs to clients. That such an infrastructure is feasible and is beneficial to all stakeholders has been amply demonstrated by Gujarat Environment Protection Industries (GEPIL) located at Surat. There is an urgent need for many more Processors / ISPs like them if co-processing is to be speeded up.

Advantages of infrastructure

The availability of infrastructure/s as explained above has several advantages. Wastes having potential as AFs would be removed as and when generated. Societies would have cleaner environment. Processors contribute greatly in creating value for wastes by converting them into AFs and AFs would most certainly be cheaper than fossil fuels. The cement industry would thus save fossil fuels and bring down CO2 emissions further.

Conclusion

There is an urgent need for stakeholders to come together and evolve a national strategy and a time- bound programme for building up infrastructure. Generators and users can come together to form sister companies or subsidiaries that could be the processors or ISPs.

Consultants and machinery designers should join to evolve tailor made systems for co-processing different types of AFs. Once the infrastructure is in position, MoEF can stipulate minimum per cent of AF by way of co-processing.

You may like

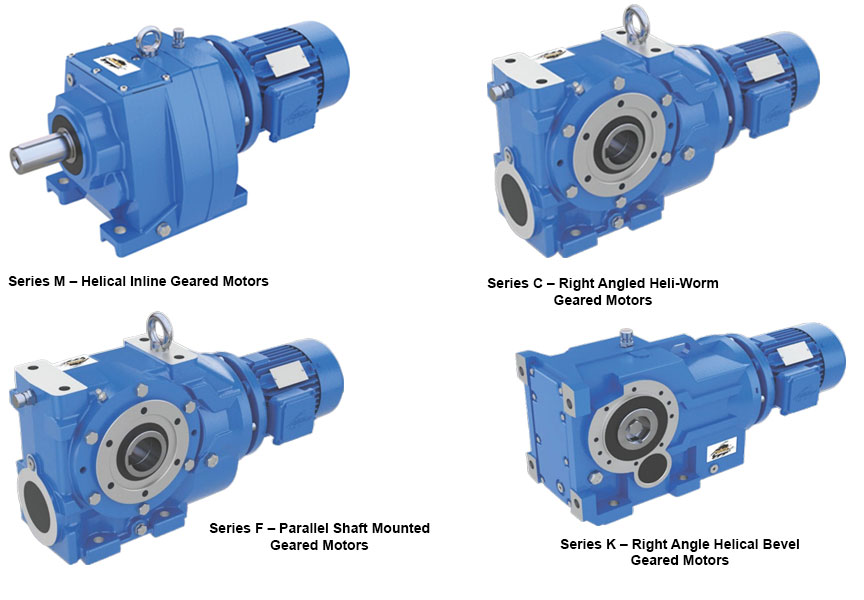

A deep dive into Core Gear Series of products M, C, F and K, by Power Build, and how they represent precision in motion.

At the heart of every high-performance industrial system lies the need for robust, reliable, and efficient power transmission. Power Build answers this need with its flagship geared motor series: M, C, F and K. Each series is meticulously engineered to serve specific operational demands while maintaining the universal promise of durability, efficiency, and performance.

Series M – Helical Inline Geared Motors

Compact and powerful, the Series M delivers exceptional drive solutions for a broad range of applications. With power handling up to 160kW and torque capacity reaching 20,000 Nm, it is the trusted solution for industries requiring quiet operation, high efficiency, and space-saving design. Series M is available with multiple mounting and motor options, making it a versatile choice for manufacturers and OEMs globally.

Series C – Right Angled Heli-Worm Geared Motors

Combining the benefits of helical and worm gearing, the Series C is designed for right-angled power transmission. With gear ratios of up to 16,000:1 and torque capacities of up to 10,000 Nm, this series is optimal for applications demanding precision in compact spaces. Industries looking for a smooth, low-noise operation with maximum torque efficiency rely on Series C for dependable performance.

Series F – Parallel Shaft Mounted Geared Motors

Built for endurance in the most demanding environments, Series F is widely adopted in steel plants, hoists, cranes and heavy-duty conveyors. Offering torque up to 10,000 Nm and high gear ratios up to 20,000:1, this product features an integral torque arm and diverse output configurations to meet industry-specific challenges head-on.

Series K – Right Angle Helical Bevel Geared Motors

For industries seeking high efficiency and torque-heavy performance, Series K is the answer. This right-angled geared motor series delivers torque up to 50,000 Nm, making it a preferred choice in core infrastructure sectors such as cement, power, mining and material handling. Its flexibility in mounting and broad motor options offer engineers the freedom in design and reliability in execution.

Together, these four series reflect Power Build’s commitment to excellence in mechanical power transmission. From compact inline designs to robust right-angle drives, each geared motor is a result of decades of engineering innovation, customer-focused design and field-tested reliability. Whether the requirement is speed control, torque multiplication or space efficiency, Radicon’s Series M, C, F and K stand as trusted powerhouses for global industries.

http://www.powerbuild.in

Call: +919727719344

Economy & Market

Conveyor belts are a vital link in the supply chain

Published

8 months agoon

June 16, 2025By

admin

Kamlesh Jain, Managing Director, Elastocon, discusses how the brand delivers high-performance, customised conveyor belt solutions for demanding industries like cement, mining, and logistics, while embracing innovation, automation, and sustainability.

In today’s rapidly evolving industrial landscape, efficient material handling isn’t just a necessity—it’s a competitive advantage. As industries such as mining, cement, steel and logistics push for higher productivity, automation, and sustainability, the humble conveyor belt has taken on a mission-critical role. In this exclusive interview, Kamlesh Jain, Managing Director, Elastocon, discusses how the company is innovating for tougher terrains, smarter systems and a greener tomorrow.

Brief us about your company – in terms of its offerings, manufacturing facilities, and the key end-user industries it serves.

Elastocon, a flagship brand of the Royal Group, is a trusted name in the conveyor belt manufacturing industry. Under the brand name ELASTOCON, the company produces both open-end and endless belts, offering tailor-made solutions to some of the most demanding sectors such as cement, steel, power, mining, fertiliser, and logistics. Every belt is meticulously engineered—from fabric selection to material composition—to ensure optimal performance in tough working conditions. With advanced manufacturing facilities and strict quality protocols, Elastocon continues to deliver high-performance conveyor solutions designed for durability, safety, and efficiency.

How is the group addressing the needs for efficient material handling?

Efficient material handling is the backbone of any industrial operation. At Elastocon, our engineering philosophy revolves around creating belts that deliver consistent performance, long operational life, and minimal maintenance. We focus on key performance parameters such as tensile strength, abrasion resistance, tear strength, and low elongation at working tension. Our belts are designed to offer superior bonding between plies and covers, which directly impacts their life and reliability. We also support clients

with maintenance manuals and technical advice, helping them improve their system’s productivity and reduce downtime.

How critical are conveyor belts in ensuring seamless material handling?

Conveyor belts are a vital link in the supply chain across industries. In sectors like mining, cement, steel, and logistics, they facilitate the efficient movement of materials and help maintain uninterrupted production flows. At Elastocon, we recognise the crucial role of belts in minimising breakdowns and increasing plant uptime. Our belts are built to endure abrasive, high-temperature, or high-load environments. We also advocate proper system maintenance, including correct belt storage, jointing, roller alignment, and idler checks, to ensure smooth and centered belt movement, reducing operational interruptions.

What are the key market and demand drivers for the conveyor belt industry?

The growth of the conveyor belt industry is closely tied to infrastructure development, increased automation, and the push for higher operational efficiency. As industries strive to reduce labor dependency and improve productivity, there is a growing demand for advanced material handling systems. Customers today seek not just reliability, but also cost-effectiveness and technical superiority in the belts they choose. Enhanced product aesthetics and innovation in design are also becoming significant differentiators. These trends are pushing manufacturers to evolve continuously, and Elastocon is leading the way with customer-centric product development.

How does Elastocon address the diverse and evolving requirements of these sectors?

Our strength lies in offering a broad and technically advanced product portfolio that serves various industries. For general-purpose applications, our M24 and DINX/W grade belts offer excellent abrasion resistance, especially for RMHS and cement plants. For high-temperature operations, we provide HR and SHR T2 grade belts, as well as our flagship PYROCON and PYROKING belts, which can withstand extreme heat—up to 250°C continuous and even 400°C peak—thanks to advanced EPM polymers.

We also cater to sectors with specialised needs. For fire-prone environments like underground mining, we offer fire-resistant belts certified to IS 1891 Part V, ISO 340, and MSHA standards. Our OR-grade belts are designed for oil and chemical resistance, making them ideal for fertiliser and chemical industries. In high-moisture applications like food and agriculture, our MR-grade belts ensure optimal performance. This diverse range enables us to meet customer-specific challenges with precision and efficiency.

What core advantages does Elastocon offer that differentiate it from competitors?

Elastocon stands out due to its deep commitment to quality, innovation, and customer satisfaction. Every belt is customised to the client’s requirements, supported by a strong R&D foundation that keeps us aligned with global standards and trends. Our customer support doesn’t end at product delivery—we provide ongoing technical assistance and after-sales service that help clients maximise the value of their investments. Moreover, our focus on compliance and certifications ensures our belts meet stringent national and international safety and performance standards, giving customers added confidence.

How is Elastocon gearing up to meet its customers’ evolving needs?

We are conscious of the shift towards greener and smarter manufacturing practices. Elastocon is embracing sustainability by incorporating eco-friendly materials and energy-efficient manufacturing techniques. In parallel, we are developing belts that seamlessly integrate with automated systems and smart industrial platforms. Our vision is to make our products not just high-performing but also future-ready—aligned with global sustainability goals and compatible with emerging technologies in industrial automation and predictive maintenance.

What trends do you foresee shaping the future of the conveyor belt industry?

The conveyor belt industry is undergoing a significant transformation. As Industry 4.0 principles gain traction, we expect to see widespread adoption of smart belts equipped with sensors for real-time monitoring, diagnostics, and predictive maintenance. The demand for recyclable materials and sustainable designs will continue to grow. Furthermore, industry-specific customisation will increasingly replace standardisation, and belts will be expected to do more than just transport material—they will be integrated into intelligent production systems. Elastocon is already investing in these future-focused areas to stay ahead of the curve.

Advertising or branding is never about driving sales. It’s about creating brand awareness and recall. It’s about conveying the core values of your brand to your consumers. In this context, why is branding important for cement companies? As far as the customers are concerned cement is simply cement. It is precisely for this reason that branding, marketing and advertising of cement becomes crucial. Since the customer is unable to differentiate between the shades of grey, the onus of creating this awareness is carried by the brands. That explains the heavy marketing budgets, celebrity-centric commercials, emotion-invoking taglines and campaigns enunciating the many benefits of their offerings.

Marketing strategies of cement companies have undergone gradual transformation owing to the change in consumer behaviour. While TV commercials are high on humour and emotions to establish a fast connect with the customer, social media campaigns are focussed more on capturing the consumer’s attention in an over-crowded virtual world. Branding for cement companies has become a holistic growth strategy with quantifiable results. This has made brands opt for a mix package of traditional and new-age tools, such as social media. However, the hero of every marketing communication is the message, which encapsulates the unique selling points of the product. That after all is crux of the matter here.

While cement companies are effectively using marketing tools to reach out to the consumers, they need to strengthen the four Cs of the branding process – Consumer, Cost, Communication and Convenience. Putting up the right message, at the right time and at the right place for the right kind of customer demographic is of utmost importance in the long run. It is precisely for this reason that regional players are likely to have an upper hand as they rely on local language and cultural references to drive home the point. But modern marketing and branding domain is exponentially growing and it would be an interesting exercise to tabulate and analyse its impact on branding for cement.

Refractory demands in our kiln have changed

Digital supply chain visibility is critical

Redefining Efficiency with Digitalisation

Cement Additives for Improved Grinding Efficiency

Digital Pathways for Sustainable Manufacturing

Refractory demands in our kiln have changed

Digital supply chain visibility is critical

Redefining Efficiency with Digitalisation

Cement Additives for Improved Grinding Efficiency

Digital Pathways for Sustainable Manufacturing

Trending News

-

Concrete4 weeks ago

Concrete4 weeks agoAris Secures Rs 630 Million Concrete Supply Order

-

Concrete4 weeks ago

Concrete4 weeks agoNITI Aayog Unveils Decarbonisation Roadmaps

-

Economy & Market3 weeks ago

Economy & Market3 weeks agoBudget 2026–27 infra thrust and CCUS outlay to lift cement sector outlook

-

Concrete4 weeks ago

Concrete4 weeks agoJK Cement Commissions 3 MTPA Buxar Plant, Crosses 31 MTPA