Concrete

The Great Indian Disruption

Published

3 years agoon

By

admin

From witnessing the entry of the Adani Group directly at No 2 position to dealing with margin compression, hike in commodity and fuel prices and decline in net profits, the Indian cement industry is living the aftermath of a big disruption.

It all started in the year 2020. As the Covid-19 pandemic hit the world, the cement industry felt its devastating effects, too. That was the beginning of the disruption. Two years later, the Indian cement industry experienced a paradigm shift with the entry of the Adani Group and the exit of Holcim. The current scenario involves the economic changes that are likely to have a long-term impact on the industry. Let us look at the great Indian disruption of the cement industry.

The Recap

According to reports, the Adani Group had been planning to enter the cement industry for some time and it had also formed a subsidiary called Adani Cement Industries Ltd in June 2021. The company was apparently planning to build an integrated plant in Kutch, Gujarat, and grinding units in Dahej, Gujarat, and Raigad, Maharashtra. It also won limestone blocks in Andhra Pradesh, Gujarat, and Rajasthan by bidding process.

The sudden entry by Adani through aggressive bidding changed the industry gesture. As soon as Holcim announced its exit from the Indian market, a brutal bidding war took place to acquire its assets, and at the end of it, the assets were acquired by the Adani Group. This is India’s largest M&A transaction in the infrastructure and materials sector.

Billionaire Gautam Adani’s entry into the cement industry with the acquisition of Holcim-listed cement assets in India, namely ACC and Ambuja Cement, for an amount of just less than $10 billion may lead to unification in the industry as large players may try to gain smaller marginal players. In a speech at an event to mark the completion of the acquisition, the Adani Group Founder and Chairman said the ports-to-energy has in a single stroke become the second largest manufacturer in the country only behind UltraTech cement. A few days after the acquisition of ACC and Ambuja Cement, Adani announced his plans to double the existing cement manufacturing capacity of 70 million tonnes per year within the next five years, putting it close to market leader UltraTech Cement, and becoming the most profitable manufacturer in India till 2030, which will definitely benefit the cement industry.

With the cement sector historically growing at 1.1 per cent to 2 per cent higher than the GDP Adani expects the cement sector to grow to 8 per cent to 10 per cent. Gautam Adani’s acquisition of cement giants Ambuja and ACC from Holcim has set off a rally in both stocks adding a sufficient amount to investors’ wealth. As per analysts, ACC and Ambuja Cement will benefit from Adani’s acquisition by acquiring 63.1 per cent of Ambuja Cement along with related assets. With the government’s push to build infrastructure in India cement demand is likely to stay strong with ACC and Ambuja to benefit in the long run, the analysts added. According to Adani, Ambuja Cement and ACC operations are energy intensive, and when combined with Adani’s renewable power generation capabilities these operations

can gain a great benefit that is a must for the Indian industry.

The entry of Adani, which renovated the boards of ACC and Ambuja Cement to reflect the largest takeover in India’s infrastructure sector, would infuse Rs 20,000 crore in Ambuja Cement through preferential allotment of shares, which will further strengthen Ambuja’s balance sheet and fulfill the capital requirements for economic development, further additions and investments in technology. This investment reveals Adani’s commitment to the cement sector and an attempt to completely transform the cement sector. With Ambuja and ACC in its fold, the Adani group will now have nine listed companies in the stock market.

Adani’s foray into the cement industry is the tip of the iceberg. The larger picture involves the exponentially growing infrastructure sector in the country. Here’s how Adani’s presence has made a difference to other players and market dynamics, and is likely to continue:

- Solidifying and unifying the company’s operations in real estate and infrastructure

- Backward integration of its assets in other heavy industries such as coal and power

- With the combined capacities of Ambuja and ACC, Adani commands the second highest cement manufacturing capacity of 70 million tonnes

- Mandatory open offers in both the companies led to their respective share prices spiking up

- Clearly Adani will aim for the No. 1 position, and that will have the company scouting for mergers and acquisitions.

- Adding to its existing capacity is another important way in which the company will try to increase cement production.

The Real Twist

The real estate market faced the repercussions of the pandemic at a maximum. Today, as the necessary corrections have been done, we are looking at changing trends, which are having a direct impact on the demand for cement.

Shraddha Kedia-Agarwal, Director, Transcon Developers, said, “In the post-Covid world, there is a shift in demand for sea-facing homes with large open spaces like balconies, terraces, courtyards, gardens, and parks in the vicinity. Work-from-home and the hybrid work culture have changed the pattern for most home buyers in the post-Covid era. Owning a home is no more a matter of investment preference, but a necessity, given the boost that a luxury residence has come to lodge in the wider perspective of the work-life choices. The latest trends of customer preferences have shifted from premium real estate to a more sophisticated approach, buyers who want to get a lifestyle that can flawlessly include the work-from-home notion, while not giving up on the lavishness and comforts of luxury living. These trends are expected to continue in 2023 as well.”

She also pointed out that with RERA ensuring transparency and laws allowing 100 per cent FDI in construction, Indian real estate is witnessing sharp investment infusions from NRIs. The new class of ultra-rich people is on a buying spree of luxury homes in global cities like Mumbai, Bangalore, etc. The Indian markets are proving their grit and potential, it is now time for investors to decide if they want to benefit from India’s future potential.

“With the rise in cement cost and other building material costs, the same will eventually be carried forward to the buyer. This is a basic entrepreneurial rule. New launches will be expensive. In their initial stages, they may be at a 10 to 20 per cent lower cost, but I am foreseeing a rise in real estate price of about 18 to 20 per cent in the near future,” says Ketan Patel, Director, Akshar Group.

Pointing out the change in consumer behaviour, he said that when the price of projects increase, there is a setback of 10 to 15 per cent in the overall sales funnel. “What we have observed over the years is that the number of enquiries go down when there is an increase in price. However, the customer who is looking to buy a house or property or upgrade does come through and convert as a customer.”

The Big Picture

The objective of the Adani Group behind this takeover is to move beyond its central business of power plants, ports, and coal mine operations and expand into new fields such as airports, data centres, and digital services. Entering the cement industry is, no doubt, a part of that plan.

With so many companies moving their manufacturing operations to India, the country’s status as a preferred manufacturing destination has become firm, and with Adani’s entry, both of these will together lead to a multiplier effect on jobs and income, higher productivity, cost-effectiveness, and higher consumption. With the entry of Adani into cement considering additional capacities in western and eastern regions in the last three-quarters Adani aims that he should be able to grow at a rate faster than the industry and outperform other competitors.

In October 2021, Prime Minister Narendra Modi launched the PM Gati Shakti- National Master Plan (NMP) for multiple modes of connectivity. Gati Shakti will drive synergy to create an outstanding, seamless transport network in India. The Gati Shakti Scheme will give a much-needed advantage to infrastructure development and handling across India which will bring economic growth and will boost the cement industry. The plans to expand highways and create new cargo terminals under the PM Gati Shakti – National Master Plan will not only boost the competitiveness of the Indian industry by lowering the cost of transportation but also lead to better connectivity between production centers and consumption markets, both domestic and global. With this Master Plan, Adani Group will benefit from the economies of scale for its infrastructure business. This will raise the demand for cement in the future.

Holcim, in a statement, had said, “The corresponding offer share prices of Rs 385 for Ambuja Cement and Rs 2,300 for ACC Cement express into cash proceeds of CHF 6.4 billion for Holcim.” As per analysts, the deal is positive from a long-term perspective as it will help them in bringing down costs, and trim debts, which will lead to better margins and high returns. The deal also highlights the growing supremacy of Indian companies to complete the last transactions with foreign players and help Adani Group increase its global impression and would also help in the backward alliance as the company is constructing airports and other infrastructure projects. This will also help the sector to turn the weaker demands that have hurt the sector so far towards the sector.

The takeover of the Holcim Group’s stake in Ambuja Cement and ACC Ltd is an opportunity to attain decarbonisation of the cement sector for India to attain targets of reducing the carbon intensity of the Indian economy to below 45 per cent by 2030 and almost nil by 2070.

The Adani Group is willing to judge all opportunities present there and will consider one that is strategically correct and available at a reasonable valuation. While with the takeover of the Holcim stake in ACC Ltd. and Ambuja Cement is an opportunity for Adani to position breakthrough technologies and raise its standards in the cement sector globally. But it is sure that Adani’s entry will affect the competition and soon Adani will fit in the hard-to-abate cement in their green dream.

The Cost Impact

The cement industry has so far not been able to improve cement prices to the required extent to pass on an increase in input energy costs.

Jatin Shah, Chief Technical Officer and Managing Director, TDD, Colliers India, “Cement price as per last report has risen by about 9 per cent in October 2022 compared to March 2022. Other components like steel, aluminium, copper, etc, which are significant contributors also remain volatile. The construction cost has gone up due to various factors like labour cost and cost of transport coupled with material price volatility. This remains a concern for the developer, contractors and will continue to impact the industry.”

He advises developers to keep an eye on the fluctuating prices. He says, “Volatile market leads to hedging of prices. We recommend the developers to remain watchful for bulk procurement and approach projects with Just in time approach, tweak contracts to bring in more materials linked to basic prices and take contractors into confidence.”

In an earlier statement from Colliers India, Ramesh Nair, Chief Executive Officer, India and Managing Director, Market Development, Asia, Colliers, commented, “Costs of key construction materials are likely to remain volatile for next few months due to uncertainties created by geo-political issues, persistent lockdowns in China and a probable global recession. Prices of key construction materials will hinge on multiple factors including global economic situation, inflation rates and supply constraints. Therefore, developers are likely to push new launches till the input prices further decline, as any further surge in the cost of construction materials would impact the timely delivery of ongoing projects and disrupt their cash flows resulting in increase in housing prices.”

Speaking about the immediate effect of the rising costs, Vinit Tiwari, Chief Sales Officer, Nuvoco Vistas Corp Ltd, says, “ Consolidation has resulted in an organised market, and processes will be streamlined as a result. We anticipate that competition will become more intense in the future as more companies enter the market with expanded capacity, but at Nuvoco, we are focusing on our key competencies: quality, innovation, and value for money. We are advancing our core competency of offering premium products while maintaining our core values. As part of our efforts, we are strengthening our supply chain and digitising the purchasing process.”

The Price Factor

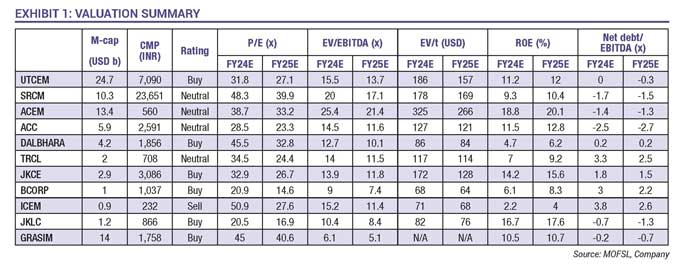

- A report by Motilal Oswal titled ‘Cement: Demand Recovery Seen but Price Volatility Continues’, the following points have been elucidated about the recovering demand for cement.

- Cement demand has recovered in the last few weeks largely driven by government infrastructure projects, while trade demand has remained muted. We expect 7 per cent demand growth YoY in 3QFY23, aided by the low base of last year. Our discussions with industry participants indicate that YTD volume growth in the non-trade segment (15 per cent YoY growth) is better than the trade segment (3-4 per cent YoY growth).

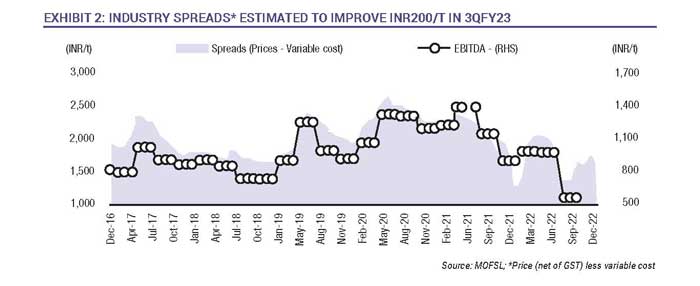

- Post 2QFY23, while the Eastern region has witnessed a consistent price improvement, the Northern and Central regions have yet to see a sustained price improvement. The pan-India average price seems to be up 2-3 per cent QoQ in 3QFY23.

- Volatility continues in coal/petcoke prices, with petcoke prices falling in Nov/Dec ’22 and coal prices increasing in the last few weeks. We expect an average energy cost reduction of Rs 50-70/t in 3QFY23 and INR100/t in 4QFY23.

- Average spreads (cement price net of GST- variable costs) for the industry is expected to improve by Rs 200/t QoQ (v/s INR300/t estimated earlier), given the rollback of price hikes announced in Nov ’22.

Demand recovers from mid-Nov ’22, east and south outperforming

- After demand weakness due to the festive season in Oct ’22, cement demand recovered from mid-Nov ’22, and we believe that volumes grew 18-20 per cent YoY in Nov ’22, aided by the absence of festive seasons and the low base of last year due to sand mining issues in the East region. We estimate combined volume growth of 6-7 per cent YoY in Oct-Nov ’22.

- We believe that cement demand is driven by improvement from the non-trade segment, largely driven by government infrastructure projects. IHB demand has yet to recover. We expect cement demand to register a growth of 5-6 per cent YoY in Dec ’22 and 7 per cent YoY in 3QFY23.

- Demand in the East and South regions seem to be strong, as per our discussions with industry participants. The demand trend is likely to remain positive, given the start of the peak construction period and pre-election government spending toward infrastructure development. We estimate overall demand growth of ~10 per cent YoY in FY23.

- The report further highlighted the pricing changes with details on the pan-India average price, which was up ~1 per cent MoM and ~7 per cent YoY in Nov ’22.

- Average cement prices increased Rs 5-15/bag MoM in the North, East, and Maharashtra markets, while they declined Rs 5/bag MoM in South India in Nov ’22. Cement prices remained flat in central India and Gujarat.

- The highest increase was seen in East India (up ~5 per cent MoM), followed by North and Maharashtra (up ~1 per cent MoM). Cement price in South India declined 2 per cent MoM (except in Kerala, up ~1 per cent). Although cement manufacturers announced price hikes of INR10/bag in Dec ’22, our channel checks indicate that cement prices have dropped by Rs 5-10/bag in the South region from 19th Dec.

- The pan-India average price seems to be up ~3 per cent QoQ in 3QFY23 QTD, with the highest increase seen in East (~9 per cent), followed by South and West (~4 per cent each). The average price is flat QoQ in the North, and there should be a marginal decline in central India (down 0.6 per cent QoQ).

Conclusion

“One of the primary concerns is that cement prices have not increased at a rate consistent with the increase in production and distribution costs. As we see it, this is an opportunity for the sector to analyse cost components by line item, from production to distribution. We are currently working on reducing our costs in order to remain competitive,” states Tiwari.

There is definitely an opportunity here. As a new year has dawned, signs of a strong demand revival are already visible for the cement sector. There are corrections in the offing with regards to lower realisations and higher operating costs. Year 2023 is looking promising for cement companies, starting with a rise in demand and price correction, which has already started in East and South India. As the government backs infrastructure projects and

real estate demand picks up pace, the year ahead looks buoyant for India’s cement sector and its disruptors.

Concrete

Our strategy is to establish reliable local partnerships

Published

7 hours agoon

February 19, 2026By

admin

Jean-Jacques Bois, President, Nanolike, discusses how real-time data is reshaping cement delivery planning and fleet performance.

As cement producers look to extract efficiency gains beyond the plant gate, real-time visibility and data-driven logistics are becoming critical levers of competitiveness. In this interview with Jean-Jacques Bois, President, Nanolike, we discover how the company is helping cement brands optimise delivery planning by digitally connecting RMC silos, improving fleet utilisation and reducing overall logistics costs.

How does SiloConnect enable cement plants to optimise delivery planning and logistics in real time?

In simple terms, SiloConnect is a solution developed to help cement suppliers optimise their logistics by connecting RMC silos in real time, ensuring that the right cement is delivered at the right time and to the right location. The core objective is to provide real-time visibility of silo levels at RMC plants, allowing cement producers to better plan deliveries.

SiloConnect connects all the silos of RMC plants in real time and transmits this data remotely to the logistics teams of cement suppliers. With this information, they can decide when to dispatch trucks, how to prioritise customers, and how to optimise fleet utilisation. The biggest savings we see today are in logistics efficiency. Our customers are able to sell and ship more cement using the same fleet. This is achieved by increasing truck rotation, optimising delivery routes, and ultimately delivering the same volumes at a lower overall logistics cost.

Additionally, SiloConnect is designed as an open platform. It offers multiple connectors that allow data to be transmitted directly to third-party ERP systems. For example, it can integrate seamlessly with SAP or other major ERP platforms, enabling automatic order creation whenever replenishment is required.

How does your non-exclusive sensor design perform in the dusty, high-temperature, and harsh operating conditions typical of cement plants?

Harsh operating conditions such as high temperatures, heavy dust, extreme cold in some regions, and even heavy rainfall are all factored into the product design. These environmental challenges are considered from the very beginning of the development process.

Today, we have thousands of sensors operating reliably across a wide range of geographies, from northern Canada to Latin America, as well as in regions with heavy rainfall and extremely high temperatures, such as southern Europe. This extensive field experience demonstrates that, by design, the SiloConnect solution is highly robust and well-suited for demanding cement plant environments.

Have you initiated any pilot projects in India, and what outcomes do you expect from them?

We are at the very early stages of introducing SiloConnect in India. Recently, we installed our

first sensor at an RMC plant in collaboration with FDC Concrete, marking our initial entry into the Indian market.

In parallel, we are in discussions with a leading cement producer in India to potentially launch a pilot project within the next three months. The goal of these pilots is to demonstrate real-time visibility, logistics optimisation and measurable efficiency gains, paving the way for broader adoption across the industry.

What are your long-term plans and strategic approach for working with Indian cement manufacturers?

For India, our strategy is to establish strong and reliable local partnerships, which will allow us to scale the technology effectively. We believe that on-site service, local presence, and customer support are critical to delivering long-term value to cement producers.

Ideally, our plan is to establish an Indian entity within the next 24 months. This will enable us to serve customers more closely, provide faster support and contribute meaningfully to the digital transformation of logistics and supply chain management in the Indian cement industry.

Pankaj Kejriwal, Whole Time Director and COO, Star Cement, on driving efficiency today and designing sustainability for tomorrow.

In an era where the cement industry is under growing pressure to decarbonise while scaling capacity, Star Cement is charting a pragmatic yet forward-looking path. In this conversation, Pankaj Kejriwal, Whole Time Director and COO, Star Cement, shares how the company is leveraging waste heat recovery, alternative fuels, low-carbon products and clean energy innovations to balance operational efficiency with long-term sustainability.

How has your Lumshnong plant implemented the 24.8 MW Waste Heat Recovery System (WHRS), and what impact has it had on thermal substitution and energy costs?

Earlier, the cost of coal in the Northeast was quite reasonable, but over the past few years, global price increases have also impacted the region. We implemented the WHRS project about five years ago, and it has resulted in significant savings by reducing our overall power costs.

That is why we first installed WHRS in our older kilns, and now it has also been incorporated into our new projects. Going forward, WHRS will be essential for any cement plant. We are also working on utilising the waste gases exiting the WHRS, which are still at around 100 degrees Celsius. To harness this residual heat, we are exploring systems based on the Organic Rankine Cycle, which will allow us to extract additional power from the same process.

With the launch of Star Smart Building Solutions and AAC blocks, how are you positioning yourself in the low-carbon construction materials segment?

We are actively working on low-carbon cement products and are currently evaluating LC3 cement. The introduction of autoclaved aerated concrete (AAC) blocks provided us with an effective entry into the consumer-facing segment of the industry. Since we already share a strong dealer network across products, this segment fits well into our overall strategy.

This move is clearly supporting our transition towards products with lower carbon intensity and aligns with our broader sustainability roadmap.

With a diverse product portfolio, what are the key USPs that enable you to support India’s ongoing infrastructure projects across sectors?

Cement requirements vary depending on application. There is OPC, PPC and PSC cement, and each serves different infrastructure needs. We manufacture blended cements as well, which allows us to supply products according to specific project requirements.

For instance, hydroelectric projects, including those with NHPC, have their own technical norms, which we are able to meet. From individual home builders to road infrastructure, dam projects, and regions with heavy monsoon exposure, where weather-shield cement is required, we are equipped to serve all segments. Our ability to tailor cement solutions across diverse climatic and infrastructure conditions is a key strength.

How are you managing biomass usage, circularity, and waste reduction across

your operations?

The Northeast has been fortunate in terms of biomass availability, particularly bamboo. Earlier, much of this bamboo was supplied to paper plants, but many of those facilities have since shut down. As a result, large quantities of bamboo biomass are now available, which we utilise in our thermal power plants, achieving a Thermal Substitution Rate (TSR) of nearly 60 per cent.

We have also started using bamboo as a fuel in our cement kilns, where the TSR is currently around 10 per cent to 12 per cent and is expected to increase further. From a circularity perspective, we extensively use fly ash, which allows us to reuse a major industrial waste product. Additionally, waste generated from HDPE bags is now being processed through our alternative fuel and raw material (AFR) systems. These initiatives collectively support our circular economy objectives.

As Star Cement expands, what are the key logistical and raw material challenges you face in scaling operations?

Fly ash availability in the Northeast is a constraint, as there are no major thermal power plants in the region. We currently source fly ash from Bihar and West Bengal, which adds significant logistics costs. However, supportive railway policies have helped us manage this challenge effectively.

Beyond the Northeast, we are also expanding into other regions, including the western region, to cater to northern markets. We have secured limestone mines through auctions and are now in the process of identifying and securing other critical raw material resources to support this expansion.

With increasing carbon regulations alongside capacity expansion, how do you balance compliance while sustaining growth?

Compliance and growth go hand in hand for us. On the product side, we are working on LC3 cement and other low-carbon formulations. Within our existing product portfolio, we are optimising operations by increasing the use of green fuels and improving energy efficiency to reduce our carbon footprint.

We are also optimising thermal energy consumption and reducing electrical power usage. Notably, we are the first cement company in the Northeast to deploy EV tippers at scale for limestone transportation from mines to plants. Additionally, we have installed belt conveyors for limestone transfer, which further reduces emissions. All these initiatives together help us achieve regulatory compliance while supporting expansion.

Looking ahead to 2030 and 2050, what are the key innovation and sustainability priorities for Star Cement?

Across the cement industry, carbon capture is emerging as a major focus area, and we are also planning to work actively in this space. In parallel, we see strong potential in green hydrogen and are investing in solar power plants to support this transition.

With the rapid adoption of solar energy, power costs have reduced dramatically – from 10–12 per unit to around2.5 per unit. This reduction will enable the production of green hydrogen at scale. Once available, green hydrogen can be used for electricity generation, to power EV fleets, and even as a fuel in cement kilns.

Burning green hydrogen produces only water and oxygen, eliminating carbon emissions from that part of the process. While process-related CO2 emissions from limestone calcination remain a challenge, carbon capture technologies will help address this. Ultimately, while becoming a carbon-negative industry is challenging, it is a goal we must continue to work towards.

Concrete

Turning Downtime into Actionable Intelligence

Published

8 hours agoon

February 19, 2026By

admin

Stoppage Insights instantly identifies root causes and maps their full operational impact.

In cement, mining and minerals processing operations, every unplanned stoppage equals lost production and reduced profitability. Yet identifying what caused a stoppage remains frustratingly complex. A single motor failure can trigger cascading interlocks and alarm floods, burying the root cause under layers of secondary events. Operators and maintenance teams waste valuable time tracing event chains when they should be solving problems. Until now.

Our latest innovation to our ECS Process Control Solution(1) eliminates this complexity. Stoppage Insights, available with the combined updates to our ECS/ControlCenter™ (ECS) software and ACESYS programming library, transforms stoppage events into clear, actionable intelligence. The system automatically identifies the root cause of every stoppage – whether triggered by alarms, interlocks, or operator actions – and maps all affected equipment. Operators can click any stopped motor’s faceplate to view what caused the shutdown instantly. The Stoppage UI provides a complete record of all stoppages with drill-down capabilities, replacing manual investigation with immediate answers.

Understanding root cause in Stoppage Insights

In Stoppage Insights, ‘root cause’ refers to the first alarm, interlock, or operator action detected by the control system. While this may not reveal the underlying mechanical, electrical or process failure that a maintenance team may later discover, it provides an actionable starting point for rapid troubleshooting and response. And this is where Stoppage Insights steps ahead of traditional first-out alarm systems (ISA 18.2). In this older type of system, the first alarm is identified in a group. This is useful, but limited, as it doesn’t show the complete cascade of events, distinguish between operator-initiated and alarm-triggered stoppages, or map downstream impacts. In contrast, Stoppage Insights provides complete transparency:

- Comprehensive capture: Records both regular operator stops and alarm-triggered shutdowns.

- Complete impact visibility: Maps all affected equipment automatically.

- Contextual clarity: Eliminates manual tracing through alarm floods, saving critical response time.

David Campain, Global Product Manager for Process Control Systems, says, “Stoppage Insights takes fault analysis to the next level. Operators and maintenance engineers no longer need to trace complex event chains. They see the root cause clearly and can respond quickly.”

Driving results

1.Driving results for operations teams

Stoppage Insights maximises clarity to minimise downtime, enabling operators to:

• Rapidly identify root causes to shorten recovery time.

• View initiating events and all affected units in one intuitive interface.

• Access complete records of both planned and unplanned stoppages

- Driving results for maintenance and reliability teams

Stoppage Insights helps prioritise work based on evidence, not guesswork:

• Access structured stoppage data for reliability programmes.

• Replace manual logging with automated, exportable records for CMMS, ERP or MES.(2)

• Identify recurring issues and target preventive maintenance effectively.

A future-proof and cybersecure foundation

Our Stoppage Insights feature is built on the latest (version 9) update to our ACESYS advanced programming library. This industry-leading solution lies at the heart of the ECS process control system. Its structured approach enables fast engineering and consistent control logic across hardware platforms from Siemens, Schneider, Rockwell, and others.

In addition to powering Stoppage Insights, ACESYS v9 positions the ECS system for open, interoperable architectures and future-proof automation. The same structured data used by Stoppage Insights supports AI-driven process control, providing the foundation for machine learning models and advanced analytics.

The latest releases also respond to the growing risk of cyberattacks on industrial operational technology (OT) infrastructure, delivering robust cybersecurity. The latest ECS software update (version 9.2) is certified to IEC 62443-4-1 international cybersecurity standards, protecting your process operations and reducing system vulnerability.

What’s available now and what’s coming next?

The ECS/ControlCenter 9.2 and ACESYS 9 updates, featuring Stoppage Insights, are available now for:

- Greenfield projects.

- ECS system upgrades.

- Brownfield replacement of competitor systems.

Stoppage Insights will also soon integrate with our ECS/UptimeGo downtime analysis software. Stoppage records, including root cause identification and affected equipment, will flow seamlessly into UptimeGo for advanced analytics, trending and long-term reliability reporting. This integration creates a complete ecosystem for managing and improving plant uptime.

(1) The ECS Process Control Solution for cement, mining and minerals processing combines proven control strategies with modern automation architecture to optimise plant performance, reduce downtime and support operational excellence.

(2) CMMS refers to computerised maintenance management systems; ERP, to enterprise resource planning; and MES to manufacturing execution systems.

Our strategy is to establish reliable local partnerships

Power Build’s Core Gear Series

Compliance and growth go hand in h and

Turning Downtime into Actionable Intelligence

FORNNAX Appoints Dieter Jerschl as Sales Partner for Central Europe

Our strategy is to establish reliable local partnerships

Power Build’s Core Gear Series

Compliance and growth go hand in h and

Turning Downtime into Actionable Intelligence