Concrete

Total Fuel Management with Biodiesel

Published

2 years agoon

By

admin

Gaurav Mathur, CEO, Global Technical Services, Mumbai, explores the avenue of greener fuel alternatives such as Biodiesel to reduce greenhouse gas emissions.

Saving the environment is our primary concern today and there is a need to reduce the consumption of petroleum products which lead to Global Warming. The combustion of petroleum diesel leads to emissions hence the usage of greener alternatives like Biodiesel will help reduce the greenhouse gases.

Biodiesel, a replacement for diesel fuel, is for use in diesel engines. It is manufactured from plant oils, animal fats or recycled cooking oil. The manufacturing process converts oils and fats into fatty acid methyl esters called FAME or Biodiesel.

Biodiesel benefits

- Renewable: The ratio of energy in fuel to the units of non- renewable energy used to produce it is about 5.5 :1 (Source: University of Idaho).

- Higher cetane number: For biodiesels, the cetane number is generally between 46 to 60 higher than that of diesel fuel which is 40-45

- Except NOx all other emissions are lower.

- Non-toxic

- Environmentally friendly: Use of Biodiesel instead of diesel reduces greenhouse emissions over 80 per cent.

- Fuel lubricity: Provides lubricity to the fuel injection system reducing friction and wear.

Total Fuel Management Services

Total Fuel Management services are for companies that need increased accuracy, accountability, security or productivity from their assets. It is normal for TFM implementers to achieve fluid reconciliation rates in excess of 99.5 per cent. It consists of hardware, controllers, and software, which are implemented as a integrated package. TFM is ideal for mines and industries including vehicle fleets/haulage, construction, ports, and non-hydrocarbon applications such as chemical supply and liquid food production.

The TFM services provided include:

• Storage, handling and dispensing

• Filtration for incoming diesel fuel receipts to remove sludge ad dirt

• Sourcing of Biodiesel (B100): optional

• Conditioning of B100 and blended fuel

• Testing of B100 and blended fuel for

quality assurance

• Storage facility and management for B100

• Equipment for blending, conditioning, dispensing and accounting

• Fuel performance booster: additives, antioxidants and biocides for storage stability

adoption of Biodiesel

The Biodiesel adoption in the country is more in the industrial or organised sector. It has been largely used by pharma and FMCG companies where diesel was used as a burner fuel. However, it is still a very small percentage of the HSD used. The usage is mostly B 20, however some of them, especially in the transport sector have tried B100 with some reports of filter clogging etc. However these may be attributed to the quality of B100 used as this varies with different manufacturers. The adoption may be less than 0.25 per cent of the total fuel consumed.

global usage of biodiesel

We are at a very early stage of Biodiesel adoption, compared to Europe and USA, where they

have more organised organisations and well

defined specifications to guide the users with support from OEMs.

In December 2020, greener alternatives like biodiesel itself produced a record production of 610 million litres in USA becoming the largest producer of biofuel in the world. India targets to produce 200 million litres of biodiesel (2021).

Global biofuel forecast

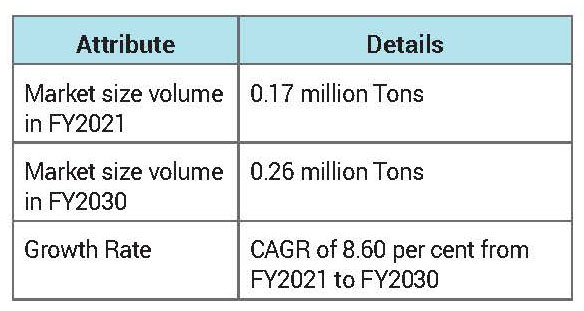

Mining, construction, transport, railways and auxiliary power generations would be industries that shall be major biodiesel end-users in India and would offer vast potential to the biofuel markets in years to come.

In mining, cement and metal mining would take the lead due to increasing sensitivity

on sustainability.

Attribute Details

Market size volume in FY2021 0.17 million Tons

Market size volume in FY2030 0.26 million Tons

Growth Rate CAGR of 8.60 per cent from FY2021 to FY2030

Construction and mining equipment sector

Sustainability should be the prime reason for implementing the usage of biodiesel, we all in the Industrial world are obliged to be sensitive to the environment and bring down the pollution levels. This is largely supported by usage of biodiesel. In absence of a clear mandate from environmental agencies, the adaptation of Biodiesel Is primarily taken as an initiative to reduce fuel cost. There should be another way, there should be incentives to the users by the agencies to adopt cleaner and green fuels such as Biodiesel. OMC’s are blending B100 with HSD , to a very small degree, yet it’s a long way to reach where we can be sustainable.

Although the intention of adaptability is good, the acceptability is in question due to fear arising out of Biodiesel quality and limited knowledge among the industry.

Supply of genuine Biodiesel is very difficult, with very few organised promoters of Biodiesel, the challenge is the supply of consistent quality

and quantity that is required by the heavy off highway machinery.

Growth prospects of biodiesel fuelled machines

The outlook is very positive for usage in terms of environmental benefits however environmental agencies strict legislation is the requirement. If the economic benefits on fuel costs is the only reason for moving to green fuels, then the adaptation shall be slow as presently one cannot define cost saving due to price variation of B100.

The key is consistency in quality and quantity, hence no single manufacturer can be identified as a sole vendor of fuel. What is needed is an

OMC or a fuel management company to take care of consistency of quality and quantity. The

future of B100 is very positive with increasing corporates and multinationals wanting to be sustainable, and OEM’s partnering in manufacturing and supporting Clean Green Fuel. The adoption of B100 in the retail market will take time due to regulatory issues.

Global Technical Services

Global Technical Services has been responsible for introducing Total Lubrication Management by implementing best lubrication practices to save millions of losses arising on account of premature failures. Core industries such as cement, mining and metals processing have hugely benefited by implementing TLM Adaptation to Clean Green Fuels is the need of the hour, already a lot of damage has been done by mankind and mother earth is already damaged to a large extent.

GTS is offering value added services to core industry where by three pillars of combustion are addressed and taken care of :

● Cleaner fuel results in better combustion. Thus, cleaning fuel and removal of all physical impurities from the diesel.

● Blending of Biodiesel with quality HSD for greener combustion.

● Quantity accounting, recording equipment wise fuel consumption, by installing WRAVI (Wireless RFID Automatic Vehicle Identification System).

The Indian cement industry, among the world’s largest, plays a pivotal role in national infrastructure and economic growth. Driven by robust demand, it continues to expand. ICR delves into the mergers and acquisitions currently underway with major cement players, in a bid to lead capacity expansion.

The Indian cement industry is one of the largest in the world, playing a crucial role in the nation’s infrastructure and economic development. Over the past few years, production has steadily increased, driven by robust demand from both urban and rural areas. Major infrastructure projects, housing developments, and government initiatives like ‘Housing for All’ and ‘Smart Cities’ have significantly boosted cement consumption.

The industry is characterised by a diverse range of players, from large multinational corporations to small local manufacturers, all contributing to a highly competitive market. Consumption trends indicate a strong preference for blended cements due to their environmental benefits and cost-effectiveness.

As the economy continues to grow, the demand for cement is expected to rise, supported by ongoing infrastructure development and urbanisation. This upward trajectory positions the Indian cement industry as a key driver of growth in the construction sector, with a focus on sustainable and innovative practices to meet future challenges.

According to the Infomerics Ratings report dated March 2023, the size of the global cement market reached US$ 363.4 billion in 2022, and it is expected to grow at a CAGR of 5.4 per cent during 2023 – 2028 to reach US$ 498.23 billion by 2028. The cement industry was expected to add 21.2 million tonnes per annum (mtpa) of manufacturing capacity in the year 2022-23. During the period, projects worth US$ 71.8 billion were expected to get commissioned. This would have been the fourth successive year, wherein the industry added more than 20 mtpa of manufacturing capacity. Between 2019-20 and 2021-22, the industry added a total of 81.1 mtpa of manufacturing capacity. The capacity utilisation of cement industries decreased from 66.2 per cent in 2018-19 to 60.3 per cent in 2021-22. There was contraction in demand and production during the pandemic.

India’s commitment to development

Infrastructure development in India is a major driver of cement demand. The government’s focus on initiatives like ‘Bharatmala’ and ‘Sagarmala’ for road and port development, along with rapid expansion in railways and airports, has significantly boosted the cement industry. Policies such as the ‘Pradhan Mantri Awas Yojana’ aim to provide affordable housing, further increasing cement consumption.

Urbanisation is accelerating in India, leading to a surge in real estate development. With a growing middle class and rising urban populations, demand for residential and commercial spaces is expanding rapidly. This urban growth is a key factor driving cement consumption, as cities expand and modernise their infrastructure to accommodate new residents and businesses.

According to Invest India, the government has committed an allocation of 3.3 per cent of GDP to the infrastructure sector in the fiscal year 2024, with particular focus on the transport and logistics segments. Roads and Highways account for the highest share, followed by Railways and Urban Public Transport. The government has set ambitious targets for the transport sector, including development of a 2 lakh-km national highway network by 2025 and expanding airports to 220. Additionally, plans include operationalising 23 waterways by 2030 and developing 35 Multi-Modal Logistics Parks (MMLPs). The total budgetary outlay for infrastructure-related ministries increased from around Rs.3.7 lakh cr in FY23 to Rs.5 lakh cr in FY24, offering investment prospects for the private sector across various transport sub-segments.

India’s cement industry also has strong export potential, with several manufacturers targeting international markets in Asia, Africa and the Middle East. The competitive pricing and quality of Indian cement make it attractive globally, contributing to increased export volumes. As global construction activities pick up, particularly in developing regions, Indian cement manufacturers are well-positioned to meet international demand, further supporting industry growth.

Anticipated growth spurt

Indian cement manufacturers are actively expanding their production capacities to meet growing domestic and international demand. Major players like UltraTech Cement, Adani Group and Shree Cement have announced significant investment plans to increase their manufacturing capabilities. This expansion is driven by factors such as robust infrastructure development, government initiatives, and rising urbanisation.

These companies are strategically enhancing capacity through both greenfield and brownfield projects, focusing on regions with high demand and logistical advantages. Innovations in technology and sustainability are also key priorities, as manufacturers aim to reduce environmental impact while increasing efficiency. This wave of capacity expansion positions the Indian cement industry to cater to future demand surges, maintaining its competitive edge in both domestic and global markets.

According to the Department for Promotion of Industry and Internal Trade (DPIIT), the Indian cement industry had an installed cement capacity of 600 million tonnes and production of 391 million tonnes of cement in 2022-23. The Crisil Market Intelligence report mentions that to cash in on rising demand from infrastructure and housing sectors, the cement industry is on course to add capacity by 150-160 million tonnes from FY25 to FY28. It also states that the industry has added capacity by 119 million tonnes (MT) per annum to reach a total of 595 MT.

The Indian cement industry is witnessing two major acquisitions in the current times. UltraTech, India’s largest cement player owned by the Aditya Birla Group, has announced that its board has approved picking up a 23 per cent non-controlling stake in India Cements in a deal valued at around Rs.1,885 crore.

While the conglomerate Adani Group has grown its capacity from almost nothing to a total of 75 mtpa in three years, positioning itself as the second-largest player in the industry. The latest growth move is the buyout of Hyderabad-based Penna Cement Industries for Rs.10,420 crore. Currently, Penna Cement has a total capacity of 10 mtpa and another 4 mtpa is under construction. Once the deal is closed, the total capacity of the Adani Group’s cement business will expand to 85 mtpa. The group aims to achieve a production capacity of 140 mtpa by 2028, while market leader UltraTech Cement has set its sights on reaching a capacity of 200 mtpa.

“This landmark acquisition is a significant step forward in Ambuja Cements’ accelerating growth journey,” said Ajay Kapur, CEO and Whole Time Director, Ambuja Cements. “By acquiring PCIL, Ambuja is poised to expand its market presence in south India and reinforce its position as a pan-India leader in the cement industry. PCIL’s strategic location and sufficient limestone reserves provide an opportunity to increase cement capacity through debottlenecking and additional investment. Importantly, the bulk cement terminals (BCTs) will prove to be a gamechanger by giving access to the eastern and southern parts of peninsular India, apart from an entry to Sri Lanka, through the sea route. Our aim is to make PCIL highly competitive on cost and productivity and improve its operating performance.”

Other cement organisations in India also have major manufacturing capacity expansion plans. Shree Cement in February 2024 announced plans for capacity development in Uttar Pradesh (UP) which outlines the development of two cement factories: one in Etah and another in Prayagraj. Both projects are expected to cost approximately `2,000 crore and increase UP’s capacity to produce cement by almost 7 mtpa over the course of the following 24 months. One of Shree Cement’s current projects is a 3.5 mtpa facility in Etah, which is expected to start up in the upcoming year. Prayagraj is planning another 3.5 mtpa facility at the same time. Nearly 17 acres of land in Etah have already been purchased by Shree Cement, and building is under construction.

“New investments made in cement production facilities automatically come with the latest technological advancements that can enhance efficiency, minimise environmental impacts, and improve the quality of cement. This leads to construction practices that are more durable and sustainable. JSW, for instance, has initiated research on the integration of supplementary cementitious materials (SCMs) like fly ash, slag, calcined clay and more. These materials not only improve the durability and strength of cement but also contribute towards reduction of carbon footprint of the cement industry. In order to meet energy demands sustainably, we must look at better industry practices such as usage of waste heat recovery systems, high-efficiency coolers and preheaters, and transition towards clean energy sources like solar or wind power,” states Jigyasa Kishore, Vice President – Enterprise Sales and Solutions, Moglix.

JK Cement in June 2024 announced the commissioning of a new grinding unit at its Prayagraj plant in Uttar Pradesh. The Prayagraj plant is a 2 mtpa clinker grinding unit project, which will increase the overall capacity of the organisation from the present 22 to 24 mtpa. This strategic move allows the company to efficiently cater to the burgeoning demand for cement across east Uttar Pradesh.

Dr Raghavpat Singhania, Managing Director, JK Cement, said, “We are thrilled to launch the new grinding unit at Prayagraj, which marks a significant milestone in our expansion strategy. As India accelerates its infrastructure development to sustain robust economic growth, we are continually scaling our capacities to cater to escalating demands from the infrastructure, housing and construction sectors. Our commitment to quality, innovation, and contributing to socio-economic development remains unwavering. We anticipate that these endeavours will not only foster our growth but also actively contribute to the overall development of the region and the nation.”

Dalmia Bharat’s cement manufacturing capacity as of May 2024 stood at 45.6 million tonnes. In the coming year, they plan to add 2.4 million tonnes in Assam and 0.5 million tonnes in Bihar. They are also in the process of acquiring cement assets from Jaiprakash Associates, which will add 9.4 million tonnes to their capacity and mark their entry into the Central region. They are currently focusing on completing ongoing projects and integrating assets like Jaypee Cement. Recently, they invested

`240 crore to expand their plant in Ariyalur, Tamil Nadu, and will add another million tonnes in Kadapa.

Commenting on the company’s expansion plans, Puneet Dalmia, Managing Director and CEO, Dalmia Bharat, said, “We continue to focus on strategic capital expenditure, maximising on the region and growth prospects and further enhancing our market position in the South. Driven by robust infrastructure development, housing and investments, we anticipate cement demand to rise. This increased capacity will facilitate the growing demand in the Southern region.”

Manufacturers are targeting specific regions that offer strategic advantages, such as proximity to raw materials, growing markets, and improved infrastructure connectivity. This regional focus helps in tapping into localised demand and reducing logistical complexities.

Kiran Patil, Managing Director, Wonder Cement, says, “We aim to increase our capacity within the next five years by establishing new plants in strategic locations across the region. These plans align well with the government’s industrial and infrastructure policies, such as the National Infrastructure Pipeline (NIP) and the push for affordable housing. These initiatives are driving demand for construction materials, and we are committed to supporting

these efforts by ensuring a steady supply of high-quality cement.”

“At Wonder Cement, we are committed to significantly expanding our production capacity to meet the growing demands of the Indian market and to contribute to the nation’s infrastructure development. Our expansion strategy is carefully aligned with the government’s industrial and infrastructure policies to ensure that our growth supports national priorities,” he adds.

The capacity expansions are set to increase the competitiveness of the Indian cement industry, with enhanced supply chains and improved market reach. This growth not only meets domestic needs but also strengthens the potential for exports, as Indian cement becomes more competitive in terms of quality and pricing on the global stage.

Overall, the expansion of manufacturing capacity by Indian cement organisations is a critical response to the dynamic market conditions, ensuring that the industry is well-prepared to support India’s developmental aspirations and maintain its competitive positioning internationally.

Rise in cement exports

India’s cement industry gained momentum with the government’s big infrastructure push for development projects. Amid global uncertainties caused by the recessionary situation in the US and EU economies, the global demand for cement has been subdued, and accordingly the cement export from India significantly decreased in half of a decade.

As per Directorate General of Commercial Intelligence and Statistics (DGCI&S), India exports Portland cement, aluminous cement, slag cement, super sulphate cement and hydraulics cements to other countries. India exports most of its concrete cement to Bangladesh, Sri Lanka and the UAE. Currently, India comes after Spain, Germany, Italy and China in the list of global cement exporters.

According to a report by SeAir Exim Solutions, India’s cement exports declined from 33,73,000 metric tonnes in 2015-16 to 11,66,000 metric tonnes in 2021-22. Cement shipments have significantly decreased in recent years. Overall, India’s cement export future depends on balancing domestic demand, global economic conditions and the industry’s ability to seize growth prospects.

The current Indian cement export scenario (2023-24) is as follows:

Cement Export Data Details

Total cement export from India 211K

Global Rank 1

Cement exporters in India 6498

Number of Indian buyers 16,150

The Infomerics Ratings report states that the cement import by India also significantly declined from 17,69,000 tonnes in 2017-18 to 7,52,000 tonnes in 2019-20 due to the pandemic. With the recovery in domestic demand, imports by India gained traction from 7,52,000 tonnes in 2019-20 to 8,16,000 tonnes in 2021-22. In 2021-22, India imported cement largely from UAE (395.1 thousand tonnes), Bangladesh (130.7 thousand tonnes), Bhutan (196.4 thousand tonnes) and Oman (41.2 thousand tonnes).

Risks and challenges

Expanding cement manufacturing capacities in India presents several risks and challenges:

- Regulatory and environmental compliance: Navigating stringent environmental regulations can be complex and costly. Manufacturers must ensure compliance with pollution control norms, which can delay projects and increase operational costs.

- Raw material availability: Securing consistent and cost-effective supplies of limestone and other raw materials is crucial. Fluctuations in availability or price can impact production and profitability.

- Logistical challenges: Efficient transportation and distribution of cement are critical. Infrastructure bottlenecks and high logistics costs can affect supply chain efficiency and market reach.

- Market saturation and competition: Rapid capacity expansion can lead to oversupply in the market, pressuring prices and margins. Intense competition among manufacturers further complicates market dynamics.

- Economic and policy uncertainty: Fluctuations in economic conditions and changes in government policies related to construction and infrastructure can affect demand, influencing investment returns and strategic planning.

Addressing these challenges requires careful planning, strategic investment, and a focus on sustainability to ensure long-term growth and competitiveness in the industry.

Conclusion

The Indian cement industry stands at a pivotal point, driven by robust infrastructure development, urbanisation, and strategic government initiatives. As manufacturers expand their capacities through significant investments in both greenfield and brownfield projects, they are positioning themselves to meet growing domestic and international demand. However, this growth trajectory is not without challenges, including regulatory hurdles, raw material availability, logistical issues and market competition.

To navigate these complexities, companies are focusing on sustainability, innovation, and strategic regional investments, ensuring they remain competitive and responsive to dynamic market conditions. As the industry continues to evolve, its ability to adapt and capitalise on emerging opportunities will be crucial in maintaining its role as a key driver of India’s economic development and infrastructure growth. With a commitment to quality and environmental responsibility, the Indian cement industry is well-equipped to support the nation’s aspirations and achieve long-term success on the global stage.

Gears, drives, and motors are essential for efficient cement production, and advancements in materials, design and technology enhance their performance. ICR discusses regular maintenance and smart manufacturing practices, including AI and IoT integration, which ensure optimal operation, reduced downtime and extended lifespan.

In the cement industry, gears, drives and motors play crucial roles in ensuring the efficient operation of machinery and equipment essential for cement production. These components are integral to various processes, including the extraction, crushing, grinding, and transportation of raw materials, as well as the production and packaging of the final cement product.

Gears are mechanical components that transmit torque and rotation from one part of a machine to another. In cement plants, gears are used in a variety of applications, such as in rotary kilns, ball mills, and crushers. They help in reducing the speed and increasing the torque to achieve the desired output for specific machinery. The types of gears commonly used include helical, bevel, and spur gears, each chosen for its specific advantages in terms of strength, efficiency, and suitability for particular tasks.

According to a market research report by IMARC, the global gear manufacturing market size reached US$ 80.0 billion in 2023. Looking forward, IMARC Group expects the market to reach US$ 131.4 billion by 2032, exhibiting a growth rate (CAGR) of 5.5 per cent during 2024-2032.

Drives refer to the mechanisms that provide the necessary power to operate various machines. In the cement industry, drive systems can be mechanical, hydraulic, or electrical. Mechanical drives, such as belt and gear drives, are often used for their simplicity and reliability. Hydraulic drives offer precise control and are used in applications where variable speed and torque are required. Electrical drives, which include variable frequency drives (VFDs), are increasingly popular for their energy efficiency and ability to provide precise speed control. Drives ensure that machinery operates at the optimal speed and torque, enhancing productivity and reducing wear and tear.

Motors are the heart of the drive systems, converting electrical energy into mechanical motion. In cement plants, motors power various machines, such as conveyors, crushers, mills, and fans. The selection of motors—whether AC, DC, synchronous, or asynchronous—depends on the specific requirements of the application, including the need for variable speed control, starting torque, and energy efficiency. Motors must be robust and reliable to withstand the harsh operating conditions typical in cement production environments.

The integration of gears, drives, and motors in the cement industry is essential for maintaining continuous and efficient operations. These components work together to ensure that machinery runs smoothly, minimising downtime and maximising output. Moreover, advancements in technology have led to the development of more efficient and durable gears, drives, and motors, contributing to the overall sustainability and cost-effectiveness of cement manufacturing processes. Their proper selection, maintenance and operation are critical to the productivity and longevity of cement plants.

Advancements and technology

Recent advancements in gear, drive, and motor technology have significantly enhanced the efficiency, reliability, and functionality of these critical components in the cement industry. These technological developments are largely driven by the principles of Industry 4.0 and smart manufacturing, which emphasise automation, data exchange, and the integration of cyber-physical systems. Advancements coupled with the transformative impact of Industry 4.0 and smart manufacturing, have revolutionised the cement industry. These innovations have led to more efficient, reliable and sustainable operations, positioning the industry for continued growth and competitiveness in the digital age.

“Advancements in gear technology have significantly enhanced the efficiency and performance of cement manufacturing processes at Wonder Cement. Modern gears, crafted from high-strength alloys and featuring advanced surface treatments, offer superior durability and wear resistance. This results in reduced friction and energy loss, allowing for more efficient power transmission. Precision engineering and innovative designs enable gears to handle higher loads with greater reliability, minimising downtime and maintenance costs. By integrating these state-of-the-art gear systems, Wonder Cement achieves optimal operational performance, ensuring that our production lines run smoothly and efficiently,” says Piyush Joshi, Associate Vice President – Systems and Technical Cell, Wonder Cement.

“The improved efficiency not only lowers energy consumption but also contributes to a more sustainable manufacturing process, aligning with our commitment to environmental stewardship and operational excellence. The incorporation of advanced technologies, including artificial intelligence (AI) and machine learning (ML), represents a significant innovation in the cement industry. At Wonder Cement, these state-of-the-art tools have been instrumental in optimising operations, reducing energy consumption and enhancing overall productivity,” he adds.

Gears have seen improvements in materials and design. The use of advanced materials, such as high-performance alloys and composite materials, has resulted in gears that are stronger, lighter and more resistant to wear and corrosion. Precision manufacturing techniques, including computer-aided design (CAD) and computer-aided manufacturing (CAM), have enabled the production of gears with tighter tolerances and better surface finishes, reducing friction and improving efficiency. Additionally, innovative lubrication solutions and surface treatments have extended the lifespan of gears, reducing maintenance needs and downtime.

Drives have benefited from the integration of digital technologies. Variable Frequency Drives (VFDs) and intelligent drive systems now offer enhanced control and flexibility, allowing for precise speed and torque adjustments to match the operational demands of cement production processes. These advanced drives are equipped with sensors and connectivity features that enable real-time monitoring and diagnostics, facilitating predictive maintenance and reducing the risk of unexpected failures. The adoption of energy-efficient drives has also contributed to significant energy savings and reduced carbon emissions.

Motors have evolved with advancements in design, materials, and control technologies. High-efficiency motors, such as permanent magnet synchronous motors (PMSMs) and brushless DC motors (BLDCs), offer superior performance and energy efficiency compared to traditional induction motors. Innovations in motor control, including the use of sophisticated algorithms and power electronics, have improved the precision and responsiveness of motor operations. Furthermore, smart motors equipped with IoT (Internet of Things) capabilities can communicate with central control systems, providing valuable data for optimising performance and maintenance schedules.

Industry 4.0 and smart manufacturing have profoundly impacted gears, drives, and motors by introducing connectivity, automation, and data analytics into the manufacturing environment. Smart sensors and IoT devices embedded in these components enable continuous monitoring of their operational status, allowing for real-time data collection and analysis. This data-driven approach facilitates predictive maintenance, where potential issues are identified and addressed before they lead to equipment failure, thereby enhancing reliability and reducing downtime.

The integration of artificial intelligence (AI) and machine learning (ML) algorithms further enhances the capabilities of smart manufacturing systems. These technologies can analyse vast amounts of data to identify patterns and optimise processes, leading to improved efficiency and productivity. For instance, AI-driven optimisation can adjust motor speeds and gear ratios in real-time to match varying loads and operational conditions, ensuring optimal performance and energy usage.

Common issues and troubleshooting

Maintaining gears, drives, and motors is essential for efficient cement plant operations, reducing downtime and extending equipment lifespan. Regular maintenance practices prevent failures and ensure reliability.

Gears require regular inspection and lubrication to avoid wear and tear. Common issues include surface wear, misalignment, and overheating. Proper alignment during installation and regular checks can prevent these problems. Using high-quality materials and maintaining a clean environment mitigates pitting and corrosion.

Drives need regular maintenance to ensure efficient operation. Mechanical drives can suffer from belt and chain wear, which requires inspection and replacement. Hydraulic drives may have leaks; tightening fittings and replacing seals can prevent this. Electrical drives can face motor burnout or VFD failure, prevented by proper wiring and avoiding overloads. Addressing excessive vibration and noise through balancing and alignment checks is also crucial.

Motors are vital to drive systems and require diligent maintenance. Bearing failures, overheating, and electrical faults are common issues. Regular lubrication, adequate cooling, and electrical inspections can prevent these problems. Vibration and noise often indicate misalignment or bearing issues, which can be detected and addressed through vibration analysis.

Troubleshooting techniques involve systematic inspection and analysis. Visual inspections, vibration analysis, thermography, lubrication analysis, and electrical testing are effective methods. Implementing a proactive maintenance strategy with regular inspections, timely lubrication, and condition monitoring enhances the reliability and longevity of gears, drives, and motors in the cement industry.

Kiran Patil, Managing Director, Wonder Cement, speaks about the company’s focus on technological advancements, sustainability and community development to support its growth while mitigating regulatory and economic challenges.

What are your company’s plans for expanding cement production capacity? How are they aligned with the government’s industrial and infrastructure policies?

In the short term, we are focusing on optimising our existing facilities and ensuring that we achieve maximum efficiency in production. Our short-term plan focuses on increasing our current production capacity by 25 per cent over the next two years to meet the rising demand for cement in infrastructure projects. This will involve brown/green field expansion, upgrading technology, enhancing operational efficiencies, and debottlenecking existing plants to achieve better throughput.

We are pleased to announce the establishment of a fifth production line at our Nimbahera facility in Chittorgarh, Rajasthan. This expansion, set to be operational by mid-2025, is in response to the growing demand in the region. The new line will augment our production capacity by an additional 2.75 MTPA.

In the long term, we aim to increase our capacity within the next five years by establishing new plants in strategic locations across the region. These plans align well with the government’s industrial and infrastructure policies, such as the National Infrastructure Pipeline (NIP) and the push for affordable housing. These initiatives are driving demand for construction materials, and we are committed to supporting these efforts by ensuring a steady supply of high-quality cement.

At Wonder Cement, we are committed to significantly expanding our production capacity to meet the growing demands of the Indian market and to contribute to the nation’s infrastructure development. Our expansion strategy is carefully aligned with the government’s industrial and infrastructure policies to ensure that our growth supports national priorities.

How have the current policies, such as the focus on infrastructure development and the ‘Make in India’ initiative, influenced your expansion plans?

The government’s emphasis on infrastructure development and the ‘Make in India’ initiative have significantly influenced our expansion plans. Policies like the NIP, which aims to enhance the quality of infrastructure across the country, have created a robust demand for construction materials. The ‘Make in India’ initiative has provided us with a favourable environment for manufacturing, encouraging us to invest more in local production. While these policies have been beneficial, the challenge lies in navigating the regulatory complexities and obtaining timely approvals for new projects. However, the government’s proactive approach in simplifying procedures and promoting ease of doing business has been encouraging.

What is your assessment of the current regulatory policies? Are there any initiatives that could help your expansion plans?

The current regulatory environment for the cement industry is generally supportive, but there is room for improvement. Simplifying and speeding up the process for environmental clearances and land acquisition would significantly facilitate our expansion plans. Additionally, policies aimed at reducing logistical costs through better infrastructure, such as improved rail and road networks, would help us optimise our supply chain and distribution. The government’s focus on digitisation and transparency in regulatory processes is a positive step that we believe will further ease the challenges associated with expansion.

How is your company securing funding for these projects, and what role do government incentives play in this process?

We are planning an investment of approximately Rs 5,000 crore over the next five to seven years to support our expansion initiatives. This includes the establishment of new plants, upgrading existing facilities, and incorporating advanced technologies. We are securing funding through a combination of internal accruals and external financing. Government incentives, such as subsidies for setting up plants in certain regions and tax benefits under the ‘Make in India’ initiative, play a crucial role in making these investments viable. These incentives help us manage costs and enhance the overall feasibility of our projects.

How is your company addressing sustainability in your expansion plans?

At Wonder Cement, environmental sustainability is a core principle guiding our expansion plans. As we increase our production capacity, we are committed to implementing measures that minimise environmental impact and promote sustainable practices. Here are the steps we are taking to ensure our new production line aligns with these values:

- Energy efficiency: We are incorporating state-of-the-art technology to enhance energy efficiency in our operations. This includes using advanced machinery that consumes less energy and optimising our processes to reduce energy wastage. We are focusing on green power for plant operation. Recently we signed an agreement for solar power supply for our newly established grinding unit at Aligarh, U.P.

- Emission control: We are investing in cutting-edge emission control systems to significantly reduce greenhouse gas emissions. Our new facility will be equipped with high-efficiency bag filters, electrostatic precipitators, and continuous emission monitoring systems to ensure compliance with stringent environmental standards.

- Alternative fuels and raw materials: We are increasing the use of alternative fuels and raw materials in our production process. This not only reduces our dependency on non-renewable resources but also helps in lowering our carbon footprint.

- Water conservation: Water is a precious resource, and we are committed to its conservation. Our new line will incorporate advanced water recycling systems and rainwater harvesting mechanisms to ensure sustainable water use.

- Waste management: We are implementing comprehensive waste management strategies to minimise waste generation and promote recycling. This includes utilising industrial waste, such as fly ash and slag, in our cement production to reduce landfill waste.

- Green belt development: We are enhancing our green belt around the Nimbahera facility by planting more trees and maintaining natural vegetation. This helps in improving air quality and creating a sustainable environment.

- Community engagement: We are engaging with local communities to promote environmental awareness and sustainability practices.

Through various CSR initiatives, we aim to educate and involve the community in our environmental efforts.

By integrating these initiatives into our expansion plans, we ensure that our increased production capacity is achieved in an environmentally responsible manner, contributing to the long-term sustainability of our operations and the well-being of the community.

How is your company leveraging technology to enhance efficiency and capacity in your cement plants?

At Wonder Cement, we leverage cutting-edge technology to enhance our plants’ efficiency and capacity through a multifaceted approach focusing on automation, digitalisation, and sustainability. Our Advanced Process Control (APC) systems optimise production with real-time data and predictive analytics, improving efficiency and reducing energy consumption. IoT-enabled devices facilitate real-time monitoring and predictive maintenance, minimising downtime and costs. Centralised control rooms utilise sophisticated software for effective oversight and quick decision-making.

We incorporate robotics for precise, efficient material handling and explore AI and machine learning to predict equipment failures and optimise maintenance. Our adoption of Waste Heat Recovery Systems (WHRS) harnesses waste heat, reducing external energy reliance and lowering our carbon footprint. Sustainability drives our technological innovations, including investments in carbon capture and alternative fuels.

In new and expanded facilities, we plan to integrate smart manufacturing technologies, blockchain for supply chain transparency, and digital twins for real-time performance optimisation. These innovations position Wonder Cement at the forefront of the industry, ensuring high-quality products while upholding our commitment to sustainability and operational excellence.

What are the major challenges and risks associated with expansion?

The major challenges include regulatory delays, fluctuations in raw material prices, and uncertainties in the economic and political landscape. To mitigate these risks, we are focusing on diversifying our supply chain to reduce dependency on a single source of raw materials and mode of transport. We are also engaging with government authorities to ensure timely clearances and support. Additionally, we are adopting a phased approach to expansion to allow flexibility and adaptability in response to changing market conditions. Risk management frameworks and contingency planning are integral parts of our strategy to navigate these challenges.

How do your expansion plans consider the impact on local communities?

Our expansion plans are designed with a strong focus on social and economic development of local communities. We prioritise hiring from local talent pools and provide extensive training programs to enhance their skills. Our Corporate Social Responsibility (CSR) initiatives include healthcare, education and infrastructure development in the regions surrounding our plants. We are also investing in community welfare programs such as building schools, and healthcare centres and ensuring access to clean drinking water. By engaging with local communities and addressing their needs, we aim to foster a positive and sustainable relationship.

Overall, this showcases our commitment to growth, sustainability, and community development while aligning with national policies and leveraging advanced technologies. Wonder Cement’s expansion plans are designed to not only meet the increasing demand for cement in India but also to support and complement the government’s vision for industrial growth and infrastructure development. We are excited about the future and are dedicated to playing a pivotal role in the nation’s progress.

– Kanika Mathur

Indian cement industry applauds budget FY25 for focusing on decarbonisation

Towards an expanding horizon

Advancing Industrial Efficiency

We are excited about the future

Strong branding can create customer loyalty

Indian cement industry applauds budget FY25 for focusing on decarbonisation

Towards an expanding horizon

Advancing Industrial Efficiency

We are excited about the future