Product development

Dalmia Bharat strengthens its refractories portfolio

Published

9 years agoon

By

admin

The refractories business of Dalmia Bharat Group has entered into an agreement with Seven Refractories to develop and supply a wide range of monolithic refractories for the Indian market.

With over 60 years of experience in Refractories, Dalmia Bharat group is a preferred partner for refractory bricks and solutions for the Indian industry, while Seven Refractories is a leading and fast growing European player in monolithic refractories. The co-operation agreement is intended to lead to a joint venture between Dalmia and Seven Refractories.

?We are committed to bringing the most advanced solutions to our customers across the iron, steel and cement industries. This partnership will combine the strengths of both companies to provide customised solutions with the latest monolithic refractory technology combined

with quicker deliveries and localised services,?said Sameer Nagpal, CEO-Refractories, Dalmia Bharat Group.

?We are excited to spread our presence in the fast-growing Indian market by partnering with a company that has earned the trust of customers through its knowledge and decades-old experience?, said Erik Zobec, Group President, Seven Refractories. ?In previous projects in India, we have built up excellent references and gained a thorough understanding of the specific requirements of the market,? he added.

The refractories business of Dalmia Bharat Group comprises two specialty companies ?OCL Refractories and Dalmia Refractories Limited. Established in 1954 as a unit of OCL India, OCL Refractories is a leading refractory supplier to domestic and international steel plants. Set up in 1959, Dalmia Refractories (previously Shri Nataraj Ceramics and Chemical Industries Ltd) is a pioneer in high alumina refractory bricks for the Indian cement industry. The group?s refractory business has four manufacturing plants in India, one in China, a Technology Center and sales representatives at strategic locations around the world. The business provides a wide range of refractory products and services to both ferrous and non-ferrous plants, including iron & steel, cement, glass, copper and hydrocarbons.

Headquartered in Diva-?a (Slovenia), Seven Refractories offers one of the largest and most advanced portfolios of monolithic refractory materials, complemented by project management and exhaustive modern installation knowledge. With a newly expanded plant in Slovenia, a greenfield plant starting at year end in Kazakhstan and seven international subsidiaries and numerous agencies, Seven Refractories serves over 300 top customers in 40 different countries.

CCI slaps Rs 6,715 crore fine on 11 cement cos

The Competition Commission has imposed more than Rs 6,700 crore penalty on 11 cement companies, including ACC and Binani, for alleged cartelisation.

Apart from penalising the Cement Manufacturers Association (CMA), the fair trade regulator has directed all the entities to?cease and desist?from indulging in any activity relating to agreement, understanding or arrangement on prices, production and supply of cement in the market.

In a release, Competition Commission of India (CCI) said that the Rs 6,715-crore penalty has been imposed on 11 cement companies and the CMA.

The latest order has been passed by the watchdog following directions issued by the Competition Appellate Tribunal, which had remanded the matter involving the cement companies to CCI for passing a fresh order. The tribunal had also set aside fine on the 10 cement firms imposed earlier.

A fine of Rs 1,147.59 crore has been imposed on ACC, while penalties on Jaiprakash Associates Ltd and Ultratech are Rs 1,323.60 crore and Rs 1,175.49 crore, respectively.

The fines on other companies are Rs 274.02 crore (Century), Rs 187.48 crore (India Cements), Rs 128.54 crore (J K Cements), Rs 490.01 crore (Lafarge), Rs 258.63 crore (Ramco), ACL (Rs 1,163.91 crore) and Binani (Rs 167.32 crore), according to the release.

Shree Cement orders 10 mills from Gebr. Pfeiffer

Shree Cement has ordered 10 mills from Gebr. Pfeiffer. This deal continues the cement producer?s expansion strategy across India through integrated cement and grinding plants.

Gebr. Pfeiffer will supply MVR 6000 R-6 raw mills with capacities of about 550t/hr and an installed drive power of 6,700 kW each for the cement plants. These installations will come equipped with MPS 2800 BK type coal mills, each featuring a 720kW drive and an integrated SLS BK classifier. MVR 6000 C-6 cement mills are planned to grind clinker and extenders at these cement plants or at grinding plants. These types of mills are already in successful operation at various sites belonging to Shree Cement. The cement producer currently runs 24 Pfeiffer mills.

Planned grinding plants will use the MVR 6000 C-6 mill to alternatively produce 300t/hr of Ordinary Portland Cement at a product fineness of 3100cm?/g acc. to Blaine or 300t/hr of Portland Pozzolana Cement containing as much as 35 per cent of fly ash at a product fineness of 3,500cm?/g acc. to Blaine or 180t/hr of ground granulated blast-furnace slag at a product fineness of 4500cm?/g acc. to Blaine. Each of the mills will come equipped with a 6,700 kW drive.

Gebr. Pfeiffer SE will supply the core components of the mill and the gear units from Europe. Its Indian subsidiary, headquartered in Noida, Gebr. Pfeiffer (India), will provide the components such as the housings of the mills and classifiers, the steel foundation parts as well as the internal parts of the classifiers. In addition, the Indian subsidiary will design the plant layout and advise the customer on the equipment it will procure on its own.

Birla Corporation to set up clinker plant in Maharashtra

Birla Corporation will set up a 3 million tonnes per annum (MTPA) clinker plant in Maharashtra to help it expand its presence in the western India market. The firm wants to build on the recent acquisition of the Rs 4,800 crore cement business of Anil Ambani-led Reliance Infrastructure (RInfra), through which it will also get the mining lease of Mukutban limestone mines situated in the Yavatmal district of Maharashtra.

Besides, the firm expects that the acquisition will help it become a pan-India player in the ?foreseeable future?. Cement accounted for 91.34 per cent of its total sales in 2015-16. The company?s turnover stood at Rs 3,768.42 crore in the period. ?The mining lease at Mukutban would enable the company to set up a clinkerisation unit of 3 MT in the foreseeable future,? Birla Corp said in a regulatory filing. Maharashtra has limestone reserves of around 1,371.43 million tonnes with extensive deposits located in Yavatmal, Chandrapur and Gadchiroli districts. Mukutban mines are known for their cement-grade deposits of limestone.

Birla Corp said: ?The company can gain a sizeable presence in the profitable western (India) market by expansion of the Mukutban operations.?

The economies of scale and the synergies from the deal will help the firm invest in manufacturing, brand and marketing among others, it added.

On the acquisition, Birla Crop in its annual report for 2015-16 said the mineral concession with Reliance Cement Company Pvt Ltd (RCCPL) will help the firm become a pan-India player in the cement space.

?The company?s expansion potential will also be enhanced with mineral concession in the states of Madhya Pradesh, Maharashtra, Rajasthan, Karnataka, Andhra Pradesh and Himachal Pradesh, enabling the company to emerge as a pan-Indian player in the foreseeable future,?it said.

It further said: ?The company will also benefit from RCCPL?s strategically located raw material sources, captive coal mine, optimum manpower, efficient operating parameters and technical capability for producing top-end quality product.? In the report, Birla Corp had said that its profitability in 2015-16 fiscal was impacted due to outsourcing of limestone at higher prices, which is a key ingredient in making cement.

?Substantial quantity of limestone was raised by mechanical means. However, it was still short of the total requirement, which has to be outsourced at substantially high rates,?it added.

Grinding coal in Colombia with LOESCHE

Having purchased the LOESCHE state-of-the art vertical roller mill for the grinding of cement, Cementos San Marcos decided one more time in favor of LOESCHE to supply another VRM for the grinding of coal. The LOESCHE Mill Type LM 35.2+2 is the sole vertical roller mill in this plant for cement grinding.

Cementos San Marcos is one of the latest additions to Colombia?s cement production base, located 20 km north of Cali. The cement plant allows the company a closer connection to regional building sites and most of its output is used for infrastructure projects as Colombia builds toll roads and links the capital Bogot? to the north. Sustainable cement production is central to the plant?s design with energy efficiency and the use of alternative fuels.

The cement plant was designed as a two-phase project to initiate a conservative market entry with the aim to more than double capacity to meet market needs within a short period of time.

The recent experience with the LOESCHE Clinker Mill gave the client the confidence to go again with LOESCHE on a coal mill for realisation of phase 2 of this project. The challenge of this project was to fit the new and larger mill in the existing plant and reuse the existing coal millGC?s foundation of a smaller capacity Raymond mill which will be replaced. The classifier and the plant ducting equipment will be part of the contract.

You may like

-

Dalmia Bharat Foundation backs CSR initiative

-

Dalmia Bharat joins fight against coronavirus with ?25 crore contribution to PM-CARES Fund

-

Industrialist Vishnu Hari Dalmia passes away

-

Adani Group to establish a cement factory in Jharkhand’s Godda

-

10-point plan for ‘Green Industrial Revolution

-

Dalmia Bharat appoints Jorge Irusta

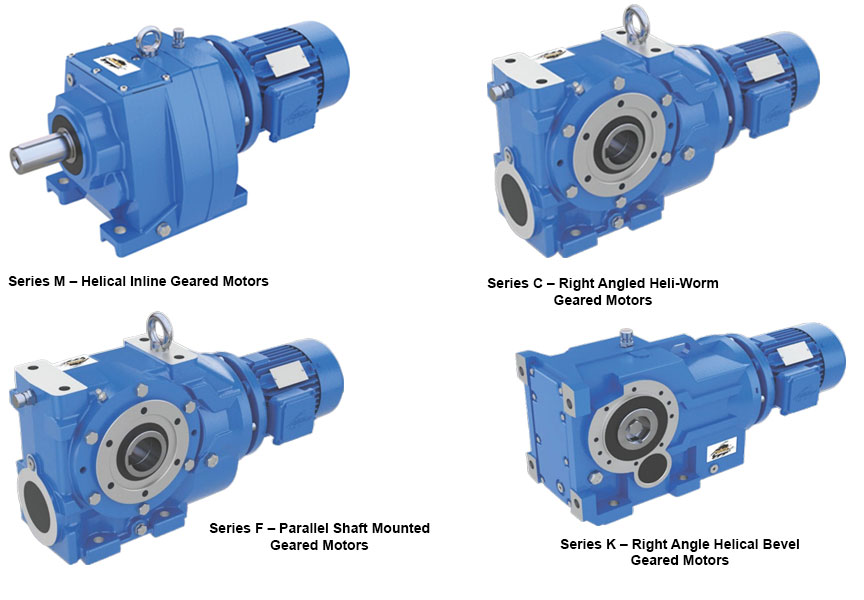

A deep dive into Core Gear Series of products M, C, F and K, by Power Build, and how they represent precision in motion.

At the heart of every high-performance industrial system lies the need for robust, reliable, and efficient power transmission. Power Build answers this need with its flagship geared motor series: M, C, F and K. Each series is meticulously engineered to serve specific operational demands while maintaining the universal promise of durability, efficiency, and performance.

Series M – Helical Inline Geared Motors

Compact and powerful, the Series M delivers exceptional drive solutions for a broad range of applications. With power handling up to 160kW and torque capacity reaching 20,000 Nm, it is the trusted solution for industries requiring quiet operation, high efficiency, and space-saving design. Series M is available with multiple mounting and motor options, making it a versatile choice for manufacturers and OEMs globally.

Series C – Right Angled Heli-Worm Geared Motors

Combining the benefits of helical and worm gearing, the Series C is designed for right-angled power transmission. With gear ratios of up to 16,000:1 and torque capacities of up to 10,000 Nm, this series is optimal for applications demanding precision in compact spaces. Industries looking for a smooth, low-noise operation with maximum torque efficiency rely on Series C for dependable performance.

Series F – Parallel Shaft Mounted Geared Motors

Built for endurance in the most demanding environments, Series F is widely adopted in steel plants, hoists, cranes and heavy-duty conveyors. Offering torque up to 10,000 Nm and high gear ratios up to 20,000:1, this product features an integral torque arm and diverse output configurations to meet industry-specific challenges head-on.

Series K – Right Angle Helical Bevel Geared Motors

For industries seeking high efficiency and torque-heavy performance, Series K is the answer. This right-angled geared motor series delivers torque up to 50,000 Nm, making it a preferred choice in core infrastructure sectors such as cement, power, mining and material handling. Its flexibility in mounting and broad motor options offer engineers the freedom in design and reliability in execution.

Together, these four series reflect Power Build’s commitment to excellence in mechanical power transmission. From compact inline designs to robust right-angle drives, each geared motor is a result of decades of engineering innovation, customer-focused design and field-tested reliability. Whether the requirement is speed control, torque multiplication or space efficiency, Radicon’s Series M, C, F and K stand as trusted powerhouses for global industries.

http://www.powerbuild.in

Call: +919727719344

Economy & Market

Conveyor belts are a vital link in the supply chain

Published

8 months agoon

June 16, 2025By

admin

Kamlesh Jain, Managing Director, Elastocon, discusses how the brand delivers high-performance, customised conveyor belt solutions for demanding industries like cement, mining, and logistics, while embracing innovation, automation, and sustainability.

In today’s rapidly evolving industrial landscape, efficient material handling isn’t just a necessity—it’s a competitive advantage. As industries such as mining, cement, steel and logistics push for higher productivity, automation, and sustainability, the humble conveyor belt has taken on a mission-critical role. In this exclusive interview, Kamlesh Jain, Managing Director, Elastocon, discusses how the company is innovating for tougher terrains, smarter systems and a greener tomorrow.

Brief us about your company – in terms of its offerings, manufacturing facilities, and the key end-user industries it serves.

Elastocon, a flagship brand of the Royal Group, is a trusted name in the conveyor belt manufacturing industry. Under the brand name ELASTOCON, the company produces both open-end and endless belts, offering tailor-made solutions to some of the most demanding sectors such as cement, steel, power, mining, fertiliser, and logistics. Every belt is meticulously engineered—from fabric selection to material composition—to ensure optimal performance in tough working conditions. With advanced manufacturing facilities and strict quality protocols, Elastocon continues to deliver high-performance conveyor solutions designed for durability, safety, and efficiency.

How is the group addressing the needs for efficient material handling?

Efficient material handling is the backbone of any industrial operation. At Elastocon, our engineering philosophy revolves around creating belts that deliver consistent performance, long operational life, and minimal maintenance. We focus on key performance parameters such as tensile strength, abrasion resistance, tear strength, and low elongation at working tension. Our belts are designed to offer superior bonding between plies and covers, which directly impacts their life and reliability. We also support clients

with maintenance manuals and technical advice, helping them improve their system’s productivity and reduce downtime.

How critical are conveyor belts in ensuring seamless material handling?

Conveyor belts are a vital link in the supply chain across industries. In sectors like mining, cement, steel, and logistics, they facilitate the efficient movement of materials and help maintain uninterrupted production flows. At Elastocon, we recognise the crucial role of belts in minimising breakdowns and increasing plant uptime. Our belts are built to endure abrasive, high-temperature, or high-load environments. We also advocate proper system maintenance, including correct belt storage, jointing, roller alignment, and idler checks, to ensure smooth and centered belt movement, reducing operational interruptions.

What are the key market and demand drivers for the conveyor belt industry?

The growth of the conveyor belt industry is closely tied to infrastructure development, increased automation, and the push for higher operational efficiency. As industries strive to reduce labor dependency and improve productivity, there is a growing demand for advanced material handling systems. Customers today seek not just reliability, but also cost-effectiveness and technical superiority in the belts they choose. Enhanced product aesthetics and innovation in design are also becoming significant differentiators. These trends are pushing manufacturers to evolve continuously, and Elastocon is leading the way with customer-centric product development.

How does Elastocon address the diverse and evolving requirements of these sectors?

Our strength lies in offering a broad and technically advanced product portfolio that serves various industries. For general-purpose applications, our M24 and DINX/W grade belts offer excellent abrasion resistance, especially for RMHS and cement plants. For high-temperature operations, we provide HR and SHR T2 grade belts, as well as our flagship PYROCON and PYROKING belts, which can withstand extreme heat—up to 250°C continuous and even 400°C peak—thanks to advanced EPM polymers.

We also cater to sectors with specialised needs. For fire-prone environments like underground mining, we offer fire-resistant belts certified to IS 1891 Part V, ISO 340, and MSHA standards. Our OR-grade belts are designed for oil and chemical resistance, making them ideal for fertiliser and chemical industries. In high-moisture applications like food and agriculture, our MR-grade belts ensure optimal performance. This diverse range enables us to meet customer-specific challenges with precision and efficiency.

What core advantages does Elastocon offer that differentiate it from competitors?

Elastocon stands out due to its deep commitment to quality, innovation, and customer satisfaction. Every belt is customised to the client’s requirements, supported by a strong R&D foundation that keeps us aligned with global standards and trends. Our customer support doesn’t end at product delivery—we provide ongoing technical assistance and after-sales service that help clients maximise the value of their investments. Moreover, our focus on compliance and certifications ensures our belts meet stringent national and international safety and performance standards, giving customers added confidence.

How is Elastocon gearing up to meet its customers’ evolving needs?

We are conscious of the shift towards greener and smarter manufacturing practices. Elastocon is embracing sustainability by incorporating eco-friendly materials and energy-efficient manufacturing techniques. In parallel, we are developing belts that seamlessly integrate with automated systems and smart industrial platforms. Our vision is to make our products not just high-performing but also future-ready—aligned with global sustainability goals and compatible with emerging technologies in industrial automation and predictive maintenance.

What trends do you foresee shaping the future of the conveyor belt industry?

The conveyor belt industry is undergoing a significant transformation. As Industry 4.0 principles gain traction, we expect to see widespread adoption of smart belts equipped with sensors for real-time monitoring, diagnostics, and predictive maintenance. The demand for recyclable materials and sustainable designs will continue to grow. Furthermore, industry-specific customisation will increasingly replace standardisation, and belts will be expected to do more than just transport material—they will be integrated into intelligent production systems. Elastocon is already investing in these future-focused areas to stay ahead of the curve.

Advertising or branding is never about driving sales. It’s about creating brand awareness and recall. It’s about conveying the core values of your brand to your consumers. In this context, why is branding important for cement companies? As far as the customers are concerned cement is simply cement. It is precisely for this reason that branding, marketing and advertising of cement becomes crucial. Since the customer is unable to differentiate between the shades of grey, the onus of creating this awareness is carried by the brands. That explains the heavy marketing budgets, celebrity-centric commercials, emotion-invoking taglines and campaigns enunciating the many benefits of their offerings.

Marketing strategies of cement companies have undergone gradual transformation owing to the change in consumer behaviour. While TV commercials are high on humour and emotions to establish a fast connect with the customer, social media campaigns are focussed more on capturing the consumer’s attention in an over-crowded virtual world. Branding for cement companies has become a holistic growth strategy with quantifiable results. This has made brands opt for a mix package of traditional and new-age tools, such as social media. However, the hero of every marketing communication is the message, which encapsulates the unique selling points of the product. That after all is crux of the matter here.

While cement companies are effectively using marketing tools to reach out to the consumers, they need to strengthen the four Cs of the branding process – Consumer, Cost, Communication and Convenience. Putting up the right message, at the right time and at the right place for the right kind of customer demographic is of utmost importance in the long run. It is precisely for this reason that regional players are likely to have an upper hand as they rely on local language and cultural references to drive home the point. But modern marketing and branding domain is exponentially growing and it would be an interesting exercise to tabulate and analyse its impact on branding for cement.

Our strategy is to establish reliable local partnerships

Power Build’s Core Gear Series

Compliance and growth go hand in h and

Turning Downtime into Actionable Intelligence

FORNNAX Appoints Dieter Jerschl as Sales Partner for Central Europe

Our strategy is to establish reliable local partnerships

Power Build’s Core Gear Series

Compliance and growth go hand in h and

Turning Downtime into Actionable Intelligence