Product development

The basic principle followed worldwide is that the polluter pays for the waste generation

Published

11 years agoon

By

admin

Axel Pieters, Head, Geocycle India

Ulhas Parlikar, Deputy Head, External Affairs, R&D, Geocycle

Geocycle India has made investments for implementing co-processing solution for the wastes and expects a reasonable return on investment for the same. However, in the Indian set up, the legislation is politically influenced. It is blocking the co-processing of waste by favouring dumping and land filling, thus becomes difficult for the cement industry to compete. In a freewheeling chat with ICR, Axel Pieters, Head, Geocycle India, and Ulhas Parlikar, Deputy Head, External Affairs, R&D, Geocycle India, elaborate on the waste management practices in India. Excerpts from the interview…

Do you think the polluter pays principle can be implemented in India, especially when it comes to waste generation?

Pieters: The basic principle followed worldwide is that the polluter pays for the waste generation. If the same thing is implemented in India, the problem can be resolved in respect of implementing solutions for the waste management. If a family of five persons, that generates about 1 tonne of wastes per year and if a user fee of Rs 500 is charged for the family per year, government can generate reasonable funds for implementing the required solutions rather than continuing with the present practice of dumping. For example, Hyderabad city alone generates 4,000 tonne of waste every day. If one decides to tax this waste, one can generate about Rs 73 crore of revenue per year which can be used to finance a treatment scheme.

In Germany, no landfill is allowed any more. In Norway and Belgium, there are huge taxes on landfill. In Eastern Europe, they are taking up first level of taxation for landfill. In most of the cities in developed countries, the waste is required to be segregated at source and stored in approved bags. Every house will have two or three containers to handle waste bags. Depending on the quantum of waste collected from the house, the family gets charged for the same. There is a fair amount of transparency in the transaction as everything is done electronically. There is equal participation in the whole process by the citizens and therefore it works.

How the waste generating industry is geared up to accept co-processing as a preferred solution? What is your contribution here?

Parlikar: Dealing with waste can be challenging and requires specialised capabilities. Geocycle ensures regulatory compliance, highest health and safety standards as well as traceability, and offers complete destruction of waste material. Our innovative and tailored solutions provide an answer to the industry?s waste challenges. The mature industry players, multinational companies or large scale industries such as automobiles, pharma, FMCG, paints, metal industry, refineries etc, are more responsive to sustainable development concept and support technologies – such as co-processing – that are aligned with it and help minimise their risk exposure and gives them peace of mind. But response from medium scale and small scale industries needs to be improved. They need to be encouraged towards sustainable technologies such as co-processing with appropriate facilitating policy level interventions.

How about options like waste to energy, burning waste in incinerator or composting?

Parlikar: Certainly, waste to energy, incineration and composting are other technologies that should be utilised for management of different kinds of wastes. Composting is the best technology for the management of bio-degradable wastes. For the non-recyclable combustible wastes, the proven technologies are co-processing, waste to energy and incineration. The capital cost and the operating cost required for implementing waste management through waste to energy or incineration technology is substantially high compared to that through co-processing technology. Hence, co-processing option is a more preferred technology world over.

Pieters: Based on the experience that I have been working for an incineration facility (with electricity generation) for about seven years in Rotterdam, I can confirm that cost wise, incineration technology is very expensive. The operating cost for an economic model of incinerator for processing one tonne of waste would be around $80-100. The other aspect is that one needs to utilise additional energy to run the incinerators. Based on the existing maturity level in the management of wastes, I believe that incinerators will co-exist along with composting and land filling operations for a reasonable time in India while implementing the co-processing solutions. Appropriate solution for India will therefore be an optimal mix of these technologies.

How do you rate the success in the propagation of AFR co-processing?

Parlikar: Geocycle India is responsible for propagation of co-processing business activity in ACC and Ambuja plants. The level of co-processing of wastes being implemented in the cement plants depends upon the location of the plant and the available waste market around it. In some locations, our plants are able to perform substantially better than others and in some locations; plants from other companies are able to demonstrate better co-processing performance.

What has been the response from the new government to waste management in general?

Parlikar: The new government is apparently very serious towards implementing systems and practices for managing wastes in environmentally sound and ecologically sustaining manner. This is apparent from the amendments being proposed in all the rules related to waste management. These new amendments are envisaging large scale reforms that are aligned towards sustainable growth. The prominent propositions in the policy framework include segregation at source, polluter pays, priority towards recycling and recovery, stringent emission norms, reduction in landfill volumes etc. All the changes in rules proposed by the new government and published on website are positive indications towards responsible and environmentally superior management of wastes.

GEOCYCLE INDIA

Geocycle was launched in 2007 as the dedicated identity for waste management solutions. It was created with an objective to uniting all activities related to the provision of waste management solutions under the single clearly positioned brand. At Geocycle, the unusable waste is converted into a safe, usable resource. Geocycle contributes to a regenerative, circular economy that closes resource cycles and minimises the wastage of scarce resources. Geocycle is a provider of waste management solutions that solves waste challenges for customers. Geocycle believes in a future with zero waste which is feasible when wastes are co-processed in cement kilns. It has dedicated experts who work persistently towards this goal. Geocycle takes the extra step to solve waste challenges faced by the industry and the society. It implements state-of-the-art technologies, tailored processes and in-depth expertise to provide sustainable, safe and reliable answers to the waste problems.

Geocycle?s promise is clear: Work relentlessly to bring society a step closer to a zero-waste future.

You may like

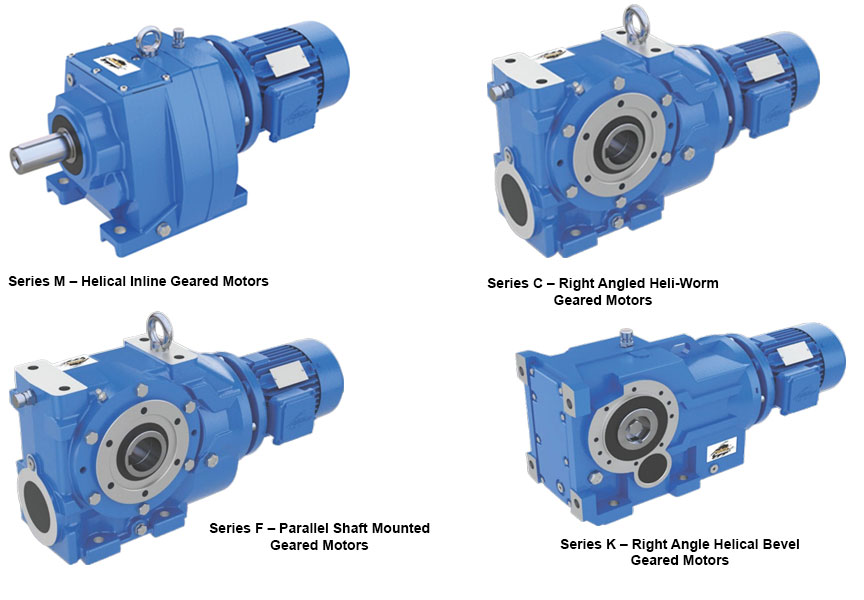

A deep dive into Core Gear Series of products M, C, F and K, by Power Build, and how they represent precision in motion.

At the heart of every high-performance industrial system lies the need for robust, reliable, and efficient power transmission. Power Build answers this need with its flagship geared motor series: M, C, F and K. Each series is meticulously engineered to serve specific operational demands while maintaining the universal promise of durability, efficiency, and performance.

Series M – Helical Inline Geared Motors

Compact and powerful, the Series M delivers exceptional drive solutions for a broad range of applications. With power handling up to 160kW and torque capacity reaching 20,000 Nm, it is the trusted solution for industries requiring quiet operation, high efficiency, and space-saving design. Series M is available with multiple mounting and motor options, making it a versatile choice for manufacturers and OEMs globally.

Series C – Right Angled Heli-Worm Geared Motors

Combining the benefits of helical and worm gearing, the Series C is designed for right-angled power transmission. With gear ratios of up to 16,000:1 and torque capacities of up to 10,000 Nm, this series is optimal for applications demanding precision in compact spaces. Industries looking for a smooth, low-noise operation with maximum torque efficiency rely on Series C for dependable performance.

Series F – Parallel Shaft Mounted Geared Motors

Built for endurance in the most demanding environments, Series F is widely adopted in steel plants, hoists, cranes and heavy-duty conveyors. Offering torque up to 10,000 Nm and high gear ratios up to 20,000:1, this product features an integral torque arm and diverse output configurations to meet industry-specific challenges head-on.

Series K – Right Angle Helical Bevel Geared Motors

For industries seeking high efficiency and torque-heavy performance, Series K is the answer. This right-angled geared motor series delivers torque up to 50,000 Nm, making it a preferred choice in core infrastructure sectors such as cement, power, mining and material handling. Its flexibility in mounting and broad motor options offer engineers the freedom in design and reliability in execution.

Together, these four series reflect Power Build’s commitment to excellence in mechanical power transmission. From compact inline designs to robust right-angle drives, each geared motor is a result of decades of engineering innovation, customer-focused design and field-tested reliability. Whether the requirement is speed control, torque multiplication or space efficiency, Radicon’s Series M, C, F and K stand as trusted powerhouses for global industries.

http://www.powerbuild.in

Call: +919727719344

Economy & Market

Conveyor belts are a vital link in the supply chain

Published

8 months agoon

June 16, 2025By

admin

Kamlesh Jain, Managing Director, Elastocon, discusses how the brand delivers high-performance, customised conveyor belt solutions for demanding industries like cement, mining, and logistics, while embracing innovation, automation, and sustainability.

In today’s rapidly evolving industrial landscape, efficient material handling isn’t just a necessity—it’s a competitive advantage. As industries such as mining, cement, steel and logistics push for higher productivity, automation, and sustainability, the humble conveyor belt has taken on a mission-critical role. In this exclusive interview, Kamlesh Jain, Managing Director, Elastocon, discusses how the company is innovating for tougher terrains, smarter systems and a greener tomorrow.

Brief us about your company – in terms of its offerings, manufacturing facilities, and the key end-user industries it serves.

Elastocon, a flagship brand of the Royal Group, is a trusted name in the conveyor belt manufacturing industry. Under the brand name ELASTOCON, the company produces both open-end and endless belts, offering tailor-made solutions to some of the most demanding sectors such as cement, steel, power, mining, fertiliser, and logistics. Every belt is meticulously engineered—from fabric selection to material composition—to ensure optimal performance in tough working conditions. With advanced manufacturing facilities and strict quality protocols, Elastocon continues to deliver high-performance conveyor solutions designed for durability, safety, and efficiency.

How is the group addressing the needs for efficient material handling?

Efficient material handling is the backbone of any industrial operation. At Elastocon, our engineering philosophy revolves around creating belts that deliver consistent performance, long operational life, and minimal maintenance. We focus on key performance parameters such as tensile strength, abrasion resistance, tear strength, and low elongation at working tension. Our belts are designed to offer superior bonding between plies and covers, which directly impacts their life and reliability. We also support clients

with maintenance manuals and technical advice, helping them improve their system’s productivity and reduce downtime.

How critical are conveyor belts in ensuring seamless material handling?

Conveyor belts are a vital link in the supply chain across industries. In sectors like mining, cement, steel, and logistics, they facilitate the efficient movement of materials and help maintain uninterrupted production flows. At Elastocon, we recognise the crucial role of belts in minimising breakdowns and increasing plant uptime. Our belts are built to endure abrasive, high-temperature, or high-load environments. We also advocate proper system maintenance, including correct belt storage, jointing, roller alignment, and idler checks, to ensure smooth and centered belt movement, reducing operational interruptions.

What are the key market and demand drivers for the conveyor belt industry?

The growth of the conveyor belt industry is closely tied to infrastructure development, increased automation, and the push for higher operational efficiency. As industries strive to reduce labor dependency and improve productivity, there is a growing demand for advanced material handling systems. Customers today seek not just reliability, but also cost-effectiveness and technical superiority in the belts they choose. Enhanced product aesthetics and innovation in design are also becoming significant differentiators. These trends are pushing manufacturers to evolve continuously, and Elastocon is leading the way with customer-centric product development.

How does Elastocon address the diverse and evolving requirements of these sectors?

Our strength lies in offering a broad and technically advanced product portfolio that serves various industries. For general-purpose applications, our M24 and DINX/W grade belts offer excellent abrasion resistance, especially for RMHS and cement plants. For high-temperature operations, we provide HR and SHR T2 grade belts, as well as our flagship PYROCON and PYROKING belts, which can withstand extreme heat—up to 250°C continuous and even 400°C peak—thanks to advanced EPM polymers.

We also cater to sectors with specialised needs. For fire-prone environments like underground mining, we offer fire-resistant belts certified to IS 1891 Part V, ISO 340, and MSHA standards. Our OR-grade belts are designed for oil and chemical resistance, making them ideal for fertiliser and chemical industries. In high-moisture applications like food and agriculture, our MR-grade belts ensure optimal performance. This diverse range enables us to meet customer-specific challenges with precision and efficiency.

What core advantages does Elastocon offer that differentiate it from competitors?

Elastocon stands out due to its deep commitment to quality, innovation, and customer satisfaction. Every belt is customised to the client’s requirements, supported by a strong R&D foundation that keeps us aligned with global standards and trends. Our customer support doesn’t end at product delivery—we provide ongoing technical assistance and after-sales service that help clients maximise the value of their investments. Moreover, our focus on compliance and certifications ensures our belts meet stringent national and international safety and performance standards, giving customers added confidence.

How is Elastocon gearing up to meet its customers’ evolving needs?

We are conscious of the shift towards greener and smarter manufacturing practices. Elastocon is embracing sustainability by incorporating eco-friendly materials and energy-efficient manufacturing techniques. In parallel, we are developing belts that seamlessly integrate with automated systems and smart industrial platforms. Our vision is to make our products not just high-performing but also future-ready—aligned with global sustainability goals and compatible with emerging technologies in industrial automation and predictive maintenance.

What trends do you foresee shaping the future of the conveyor belt industry?

The conveyor belt industry is undergoing a significant transformation. As Industry 4.0 principles gain traction, we expect to see widespread adoption of smart belts equipped with sensors for real-time monitoring, diagnostics, and predictive maintenance. The demand for recyclable materials and sustainable designs will continue to grow. Furthermore, industry-specific customisation will increasingly replace standardisation, and belts will be expected to do more than just transport material—they will be integrated into intelligent production systems. Elastocon is already investing in these future-focused areas to stay ahead of the curve.

Advertising or branding is never about driving sales. It’s about creating brand awareness and recall. It’s about conveying the core values of your brand to your consumers. In this context, why is branding important for cement companies? As far as the customers are concerned cement is simply cement. It is precisely for this reason that branding, marketing and advertising of cement becomes crucial. Since the customer is unable to differentiate between the shades of grey, the onus of creating this awareness is carried by the brands. That explains the heavy marketing budgets, celebrity-centric commercials, emotion-invoking taglines and campaigns enunciating the many benefits of their offerings.

Marketing strategies of cement companies have undergone gradual transformation owing to the change in consumer behaviour. While TV commercials are high on humour and emotions to establish a fast connect with the customer, social media campaigns are focussed more on capturing the consumer’s attention in an over-crowded virtual world. Branding for cement companies has become a holistic growth strategy with quantifiable results. This has made brands opt for a mix package of traditional and new-age tools, such as social media. However, the hero of every marketing communication is the message, which encapsulates the unique selling points of the product. That after all is crux of the matter here.

While cement companies are effectively using marketing tools to reach out to the consumers, they need to strengthen the four Cs of the branding process – Consumer, Cost, Communication and Convenience. Putting up the right message, at the right time and at the right place for the right kind of customer demographic is of utmost importance in the long run. It is precisely for this reason that regional players are likely to have an upper hand as they rely on local language and cultural references to drive home the point. But modern marketing and branding domain is exponentially growing and it would be an interesting exercise to tabulate and analyse its impact on branding for cement.

Our strategy is to establish reliable local partnerships

Power Build’s Core Gear Series

Compliance and growth go hand in h and

Turning Downtime into Actionable Intelligence

FORNNAX Appoints Dieter Jerschl as Sales Partner for Central Europe

Our strategy is to establish reliable local partnerships

Power Build’s Core Gear Series

Compliance and growth go hand in h and

Turning Downtime into Actionable Intelligence