Product Development

At Wonder Cement, the employees initiate CSR activities

Published

11 years agoon

By

admin

Vivek Patni Whole time Director, Wonder Cement

Wonder Cement is part of the RK Marble group which has the distinction of being one of the leading names in the marble industry. The company lays strong emphasis on the responsibility the corporate sector has towards society and has identified the role the company has to play in this area. It is committed to serving the communities in the vicinity of its operation with the aim of improved community welfare in tandem with company progress. Vivek Patni interacted with ICR and shared his vision to do good for the society. CSR is integrated in the DNA of values at Wonder Cement, and is not just a directive to be followed by the company. Excerpts from the interview.

What is your understanding of CSR and why is it necessary?

R K Group and Wonder Cement has always been at the fore-front in the discharge of CSR. To us CSR is not just a fraction of a campaign period. We understand the root cause of the issue we undertake and ensure to do best possible within our abilities. For instance, within the medical field, infrastructure was a barrier for providing facilities, so we have built medical infrastructures at various districts and organised medical camps at required places. CSR becomes extremely essential for today?s Indian corporates as the nation is at a stage where development of all will be more beneficial rather than an individualistic approach.

We at Wonder Cement believe in development of all and giving back to the society as much as it is given to us.

Tell us about the involvement of your staff, HR team, etc., in the CSR initiative. Our employees correlate with the visions and understandings of the company, and they give their heart-filled contributions to the initiatives the company undertakes. At Wonder Cement, the employees initiate CSR activities, while the management supports them wholeheartedly.

Tell us about your CSR activities in detail.

Diwali Activity:

Wonder Cement has recently celebrated Diwali with 45 under privileged kids cared for by an NGO at Jaipur. Diwali celebrations with sparkling lights, a puppet show, a hearty meal, loads of gifts and a family to enjoy with, got bright smiles on the face of kids, which were priceless. Wonder Cement team organised this in an association with Ashray Care Home. Arun Sharma, Vice President, Marketing, Wonder Cement distributed the gifts amongst the the kids.

Education

R K Group has always been fore-front in the discharge of CSR. This is evident in the sphere of education where the company has invested liberally towards building of schools, and colleges, with special emphasis on girls? education. It has offered scholarships to needy and poor students, benefiting nearly 1800 of them. It has already constructed 16 schools, hostels and colleges and the number is still growing.

Scholarships and Educational Institutions

R K Group has contributed immensely in the field of education under its corporate social responsibility. They have demonstrated an unstinted support to the cause of building infrastructure facilities for the spread of education. It has built a large number of school buildings and distributed scholarship. As on date, 1800 students have been benefitted through these scholarships. Also financial assistance for professional education for Engineering, MBA, MBBS, C.A/CS etc. is being provided to various students from time to time.

School Adoption

RK Groups subsidiary Wonder Cement Ltd. in partnership with Sarva Shiksha Abhiyan has adopted 20 government schools in October 2012. This partnership has augmented essential facilities like separate toilet for girls and boys, drinking water, pathways, furniture, minor repairing etc., in schools. Tangible changes have happened in these schools. Education Kit

1024 students were provided with complete set of stationery, notebooks packed in a bag during academic session 2013-14 by RK Groups subsidiary Wonder Cement students in need are provided with sweaters and dresses.

Health Care

R K Marbles has always been in the forefront in providing suitable health care to the public. Constant efforts are made to reach out to people in need and serve them wholeheartedly. More than 40,000 people have been served till now.

Medical Camps

RK Group organises various medical camps like eye camp, Viklang Sahayta Camp, ENT camp. These camps are conducted yearly as well as monthly. Till now more than 40,000 people have been served through these camps and number is growing every month.

Medical Infrastructure

Infrastructure facilities have been created by the company at various places. Contribution were made to district Health Society to construct G.N.M. Training Institute at Chittorgarh.

District Health Society, Chittorgarh to procure 50 bed sets for patients at SanwariyaJi Government General Hospital. Development of Shri Ratanlal Kanwarlal Patni Emergency Hospital in Kishangarh.

Health and Family Welfare

Family Planning Program Beneficiaries of National Family Planning Program are provided incentive through partnership with District Health Society, Chittorgarh by RK Groups subsidiary Wonder Cement. More than 90 per cent women took sterilisation as family planning option. 1319 patients of Nimbahera block in 2012-13 were given woolen blanket besides cash incentive from government.

Community Infrastructure Development

Development of Infrastructure is focused by RK Group in nearby communities. We have constructed class room, school boundary wall, concrete, bitumen and gravel roads, community center, and renovation of Anganwaries and Community Health Centre. In Chittorgarh, some facilities like renovation of Police Conference Hall, Swimming pool, Tennis court at staff club were done by RK Group.

RK Group subsidiary, RK Marble constructed the most modern ?R.K. Community Centre? with all facilities at Kishangarh for public utility and now plans to construct a Shri Ratanlal Kanwarlal Patni Athithi Awas in the Campus of R.K. Community Centre to provide more facilities to the public of Kishangarh and surrounding area.

Community Centre

Wonder Cement has constructed center for village of Rasulpura and existing hall was renovated. Earlier villagers used to face problem in organising common festivals, marriage programs. Now this community center has become very much useful for villagers. Construction of community center at Phalwa village is also being considered.

Drinking Water Arrangements

Water pipe lines, repairing of submersible pump and installation of new submersible pump was supported by RK Groups subsidiary Wonder Cement to provide drinking water at their reach.

Road Construction

RK Group has constructed 820 mtr bitumen and cement concrete road in Village. Gravel roads of 6000 mtr in nearby villages were constructed to improve the road condition in five villages.

Village Infrastructure development

Wonder Cement partnered with government?s Jan Sahbhagita schemes to improve facilities at crematorium sites in eight villages. Drinking water tanks ?Pyau? for animal were renovated with proper drainage system to improve hygiene of villagers. Financial support for construction or renovation of temples were provided. Financial support to Gram Panchayat is also provided to conduct development activities as per their plans.

Women Empowerment

The company provided sewing training to women in the village. This center is shifted from village to village after completion of each batch. Women get quality training from trainer who is expert in the art of tailoring. Most women are stitching salwar suit, mobile cover, bag, foot mate, paper holder, table cover, tiffin cover, etc. So far Wonder Cement has trained 179 women through eight batches of four villages.

Women and Child Development Program

Four Anganwari Centres of nearby villages were renovated and child friendly environment was created. Playing and Learning materials were provided. Walls were painted as per curriculum of pre-school learning. Self help groups of women were created to connect them with income generating activities.

Swacha Gaon Nirogi Gaon Programme

This sanitation programme aims to stop open defecation in villages. RK Group subsidiary Wonder Cement signed a tripartite agreement with Zila Parishad, Chittorgarh and two NGOs experienced in sanitation field to support construction of 1000 individual household toilets. With the help of the third party NGO?s sanitation facilities will be installed in seven villages of nearby plant area (Rasulpura, Peerkhera, Phalwa, Bhattkotri, Borakheri, Sangria and BadoliMadhosingh).

So far 327 toilets were constructed. Pre casted cement slab are used for constructing super structure of toilet and soakage pits are constructed using bricks in honey combing method. Awareness programme for better hygiene practices are regularly conducted to make these villages free from the ill practice of open defecation.

What are your priorities while framing a CSR plan?

Wonder Cement plans to accomplish its CSR targets focused on education, healthcare, infrastructure, community development, etc. We undertake activities that give self motivation to our employees for giving back to the society. We wish to do more in the lines of the new government regulations and motivate more and more common people to contribute their bit to the rest of the society.

Apart from doing good to the society, CSR helps the contributing organisation too in several ways. Please list some of the benefits that you have realised.

While we undertake these activities the management and the employees get together and work on one page, bond is indeed strengthened! It is through these activities that we get to interface with people who somewhere contribute to our company?s growth and success.

Quick Facts

Tree plantation done in 123 hectares (43 by RK Marble+ 80 by Wonder Cement) around the operational areas.

About 40,000 people served with health care services provided by the company.

More than 1800 students were given financial assistance for basic and higher education.

1000 households get good sanitation facilities.

You may like

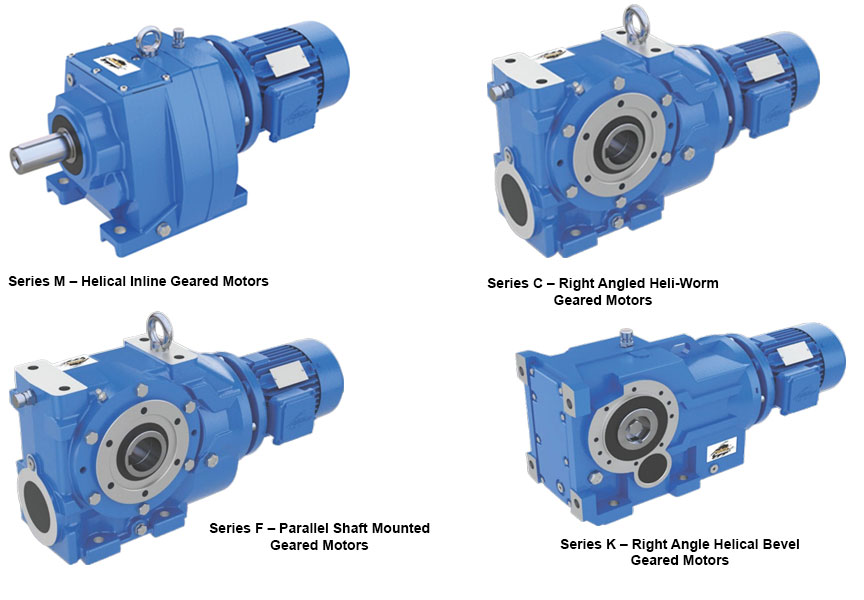

A deep dive into Core Gear Series of products M, C, F and K, by Power Build, and how they represent precision in motion.

At the heart of every high-performance industrial system lies the need for robust, reliable, and efficient power transmission. Power Build answers this need with its flagship geared motor series: M, C, F and K. Each series is meticulously engineered to serve specific operational demands while maintaining the universal promise of durability, efficiency, and performance.

Series M – Helical Inline Geared Motors

Compact and powerful, the Series M delivers exceptional drive solutions for a broad range of applications. With power handling up to 160kW and torque capacity reaching 20,000 Nm, it is the trusted solution for industries requiring quiet operation, high efficiency, and space-saving design. Series M is available with multiple mounting and motor options, making it a versatile choice for manufacturers and OEMs globally.

Series C – Right Angled Heli-Worm Geared Motors

Combining the benefits of helical and worm gearing, the Series C is designed for right-angled power transmission. With gear ratios of up to 16,000:1 and torque capacities of up to 10,000 Nm, this series is optimal for applications demanding precision in compact spaces. Industries looking for a smooth, low-noise operation with maximum torque efficiency rely on Series C for dependable performance.

Series F – Parallel Shaft Mounted Geared Motors

Built for endurance in the most demanding environments, Series F is widely adopted in steel plants, hoists, cranes and heavy-duty conveyors. Offering torque up to 10,000 Nm and high gear ratios up to 20,000:1, this product features an integral torque arm and diverse output configurations to meet industry-specific challenges head-on.

Series K – Right Angle Helical Bevel Geared Motors

For industries seeking high efficiency and torque-heavy performance, Series K is the answer. This right-angled geared motor series delivers torque up to 50,000 Nm, making it a preferred choice in core infrastructure sectors such as cement, power, mining and material handling. Its flexibility in mounting and broad motor options offer engineers the freedom in design and reliability in execution.

Together, these four series reflect Power Build’s commitment to excellence in mechanical power transmission. From compact inline designs to robust right-angle drives, each geared motor is a result of decades of engineering innovation, customer-focused design and field-tested reliability. Whether the requirement is speed control, torque multiplication or space efficiency, Radicon’s Series M, C, F and K stand as trusted powerhouses for global industries.

http://www.powerbuild.in

Call: +919727719344

Economy & Market

Conveyor belts are a vital link in the supply chain

Published

8 months agoon

June 16, 2025By

admin

Kamlesh Jain, Managing Director, Elastocon, discusses how the brand delivers high-performance, customised conveyor belt solutions for demanding industries like cement, mining, and logistics, while embracing innovation, automation, and sustainability.

In today’s rapidly evolving industrial landscape, efficient material handling isn’t just a necessity—it’s a competitive advantage. As industries such as mining, cement, steel and logistics push for higher productivity, automation, and sustainability, the humble conveyor belt has taken on a mission-critical role. In this exclusive interview, Kamlesh Jain, Managing Director, Elastocon, discusses how the company is innovating for tougher terrains, smarter systems and a greener tomorrow.

Brief us about your company – in terms of its offerings, manufacturing facilities, and the key end-user industries it serves.

Elastocon, a flagship brand of the Royal Group, is a trusted name in the conveyor belt manufacturing industry. Under the brand name ELASTOCON, the company produces both open-end and endless belts, offering tailor-made solutions to some of the most demanding sectors such as cement, steel, power, mining, fertiliser, and logistics. Every belt is meticulously engineered—from fabric selection to material composition—to ensure optimal performance in tough working conditions. With advanced manufacturing facilities and strict quality protocols, Elastocon continues to deliver high-performance conveyor solutions designed for durability, safety, and efficiency.

How is the group addressing the needs for efficient material handling?

Efficient material handling is the backbone of any industrial operation. At Elastocon, our engineering philosophy revolves around creating belts that deliver consistent performance, long operational life, and minimal maintenance. We focus on key performance parameters such as tensile strength, abrasion resistance, tear strength, and low elongation at working tension. Our belts are designed to offer superior bonding between plies and covers, which directly impacts their life and reliability. We also support clients

with maintenance manuals and technical advice, helping them improve their system’s productivity and reduce downtime.

How critical are conveyor belts in ensuring seamless material handling?

Conveyor belts are a vital link in the supply chain across industries. In sectors like mining, cement, steel, and logistics, they facilitate the efficient movement of materials and help maintain uninterrupted production flows. At Elastocon, we recognise the crucial role of belts in minimising breakdowns and increasing plant uptime. Our belts are built to endure abrasive, high-temperature, or high-load environments. We also advocate proper system maintenance, including correct belt storage, jointing, roller alignment, and idler checks, to ensure smooth and centered belt movement, reducing operational interruptions.

What are the key market and demand drivers for the conveyor belt industry?

The growth of the conveyor belt industry is closely tied to infrastructure development, increased automation, and the push for higher operational efficiency. As industries strive to reduce labor dependency and improve productivity, there is a growing demand for advanced material handling systems. Customers today seek not just reliability, but also cost-effectiveness and technical superiority in the belts they choose. Enhanced product aesthetics and innovation in design are also becoming significant differentiators. These trends are pushing manufacturers to evolve continuously, and Elastocon is leading the way with customer-centric product development.

How does Elastocon address the diverse and evolving requirements of these sectors?

Our strength lies in offering a broad and technically advanced product portfolio that serves various industries. For general-purpose applications, our M24 and DINX/W grade belts offer excellent abrasion resistance, especially for RMHS and cement plants. For high-temperature operations, we provide HR and SHR T2 grade belts, as well as our flagship PYROCON and PYROKING belts, which can withstand extreme heat—up to 250°C continuous and even 400°C peak—thanks to advanced EPM polymers.

We also cater to sectors with specialised needs. For fire-prone environments like underground mining, we offer fire-resistant belts certified to IS 1891 Part V, ISO 340, and MSHA standards. Our OR-grade belts are designed for oil and chemical resistance, making them ideal for fertiliser and chemical industries. In high-moisture applications like food and agriculture, our MR-grade belts ensure optimal performance. This diverse range enables us to meet customer-specific challenges with precision and efficiency.

What core advantages does Elastocon offer that differentiate it from competitors?

Elastocon stands out due to its deep commitment to quality, innovation, and customer satisfaction. Every belt is customised to the client’s requirements, supported by a strong R&D foundation that keeps us aligned with global standards and trends. Our customer support doesn’t end at product delivery—we provide ongoing technical assistance and after-sales service that help clients maximise the value of their investments. Moreover, our focus on compliance and certifications ensures our belts meet stringent national and international safety and performance standards, giving customers added confidence.

How is Elastocon gearing up to meet its customers’ evolving needs?

We are conscious of the shift towards greener and smarter manufacturing practices. Elastocon is embracing sustainability by incorporating eco-friendly materials and energy-efficient manufacturing techniques. In parallel, we are developing belts that seamlessly integrate with automated systems and smart industrial platforms. Our vision is to make our products not just high-performing but also future-ready—aligned with global sustainability goals and compatible with emerging technologies in industrial automation and predictive maintenance.

What trends do you foresee shaping the future of the conveyor belt industry?

The conveyor belt industry is undergoing a significant transformation. As Industry 4.0 principles gain traction, we expect to see widespread adoption of smart belts equipped with sensors for real-time monitoring, diagnostics, and predictive maintenance. The demand for recyclable materials and sustainable designs will continue to grow. Furthermore, industry-specific customisation will increasingly replace standardisation, and belts will be expected to do more than just transport material—they will be integrated into intelligent production systems. Elastocon is already investing in these future-focused areas to stay ahead of the curve.

Advertising or branding is never about driving sales. It’s about creating brand awareness and recall. It’s about conveying the core values of your brand to your consumers. In this context, why is branding important for cement companies? As far as the customers are concerned cement is simply cement. It is precisely for this reason that branding, marketing and advertising of cement becomes crucial. Since the customer is unable to differentiate between the shades of grey, the onus of creating this awareness is carried by the brands. That explains the heavy marketing budgets, celebrity-centric commercials, emotion-invoking taglines and campaigns enunciating the many benefits of their offerings.

Marketing strategies of cement companies have undergone gradual transformation owing to the change in consumer behaviour. While TV commercials are high on humour and emotions to establish a fast connect with the customer, social media campaigns are focussed more on capturing the consumer’s attention in an over-crowded virtual world. Branding for cement companies has become a holistic growth strategy with quantifiable results. This has made brands opt for a mix package of traditional and new-age tools, such as social media. However, the hero of every marketing communication is the message, which encapsulates the unique selling points of the product. That after all is crux of the matter here.

While cement companies are effectively using marketing tools to reach out to the consumers, they need to strengthen the four Cs of the branding process – Consumer, Cost, Communication and Convenience. Putting up the right message, at the right time and at the right place for the right kind of customer demographic is of utmost importance in the long run. It is precisely for this reason that regional players are likely to have an upper hand as they rely on local language and cultural references to drive home the point. But modern marketing and branding domain is exponentially growing and it would be an interesting exercise to tabulate and analyse its impact on branding for cement.

Refractory demands in our kiln have changed

Digital supply chain visibility is critical

Redefining Efficiency with Digitalisation

Cement Additives for Improved Grinding Efficiency

Digital Pathways for Sustainable Manufacturing

Refractory demands in our kiln have changed

Digital supply chain visibility is critical

Redefining Efficiency with Digitalisation

Cement Additives for Improved Grinding Efficiency

Digital Pathways for Sustainable Manufacturing

Trending News

-

Concrete4 weeks ago

Concrete4 weeks agoAris Secures Rs 630 Million Concrete Supply Order

-

Concrete3 weeks ago

Concrete3 weeks agoNITI Aayog Unveils Decarbonisation Roadmaps

-

Concrete3 weeks ago

Concrete3 weeks agoJK Cement Commissions 3 MTPA Buxar Plant, Crosses 31 MTPA

-

Economy & Market3 weeks ago

Economy & Market3 weeks agoBudget 2026–27 infra thrust and CCUS outlay to lift cement sector outlook