Concrete

Durable concrete for tunnelling application

Published

14 years agoon

By

admin

In this first part of the two-part series, EugenKleen of Mc-Bauchemie Mueller GmbH and Co.KG spells out the properties required in concrete and the types of concrete used in tunnelling application.Over the decade the use of concrete admixtures, especially plasticizers and superplasticizers, is showing upward trend in India. The advent of concrete pumps and transit mixers has also contributed to this, as the use of superplasticizers enables trouble-free pumping operations and minimizes pipe blockages. With the advent of major metro projects across India, durability of concrete used especially for tunnelling segments is of prime importance. The earlier attitude of taking recourse to the use of admixtures only after facing problems is changing fast, and now, in most tunnelling projects, high performing admixtures are already included in the specifications and the mix is designed to achieve the necessary properties.The concrete for tunnel segments necessitates the concrete to have the following properties:??Compressive strength??Workability??Surface finish??DurabilityAs part of the durability requirements, concrete is or should be generally tested for the following properties:??Chloride migration??Sulfate resistance??Water absorption??Acid resistance??Porosity??Freeze thaw resistanceThis can be achieved using the latest technologies available for concrete. Concrete is now no longer a material consisting of cement, aggregates, water and admixtures but it is an engineered material with several new constituents like PFA, GGBSF, Microsilica, Metakaolin, Colloidal Sillica and several other binders, fillers and pozzolanic materials. The concrete today can take care of any specific requirements under most exposure conditions.The mix designs are getting relatively complex on account of interaction of several materials and mix design calls for expertise in concrete technology and materials. High performance concretes will have to be adapted for tunnelling segments, considering special properties as well as low cost maintenance strategies.What type of concrete do we use?Concrete used in tunnelling applications need the following outstanding properties viz. Compressive strength, high workability, enhanced resistances to chemical or mechanical stresses, lower permeability, durability etc. this will necessitate the use of high performance concrete. Some HPC types which will hold the key for tunnelling applications can be classified into:??Self compacting concrete / high workability concrete??Concretes resistant against aggressive mediaSelf-Compacting Concrete (SCC)Self-Compacting or Consolidating Concrete (SCC), as the name signifies should be able to compact itself by its self-weight under gravity without any additional vibrations or compaction. Self compacting concrete should be able to assume any complicated formwork shapes without cavities and entrapment of air. The reinforcement should be effectively covered and the aggregated should be fully soaked in the concrete matrix. In addition, the concrete should be self-levelling type and self-defoaming without any external compaction.The formulation of self compacting concrete has the latest concrete technology and it requires in-depth knowledge of materials and meticulous testing procedures before the concrete is designated as SCC. Self compacting concrete has the following special advantages.??Saving of cost on machinery, energy and personnel for vibrating the concrete??Considerable improvements to exposed surfaces (Fair Faced Concrete), less efflorescence??Marked improvements in durability on account of better compaction??Extremely suitable for slim and complicated moulds??Covers reinforcement effectively??Better adhesive between cement binder and aggregates??Reduction in de-moulding time??Advantage with respect to sound pollutionTherefore while calculating the costing and economics of self compacting concrete all the above mentioned advantages should be converted to cost parameters. This kind of concrete can give advantage of good compressive strength, workability and finish to the tunnel segments and may prove suitable.Durable concrete resistant against aggressive mediaOne major application of HPC is to increase the durability of concrete where aggressive underground conditions are anticipated. This can be achieved physically by resorting to very dense aggregate packing.Practically possible by selecting a very smooth sieve line from largest aggregate to the smallest grain of mineral additives like microsilica or new generation aluminosilicate slurries. Chemically, cement by itself is not acid resistant. The acid resistant binder is formed by combination of cement, microsilica / aluminosilicate and flyash. To control permeability very low water cement ratio has to be adopted. So as to provide the essential concrete properties a high-performance PCE (polycarboxylate ether) needs to be incorporated in the mix. By adjusting the particle size distribution on the micro scale the permeability of the concrete is reduced which minimizes the penetration of aggressive substances. Depending on the degree of dispersion these material particles more or less completely fill the spaces between the cement particles. During hydration the pozzolanic silica reacts with the free calcium hydroxide to form calcium silicate hydrates. This gives a denser concrete structure.(Source: Paper presented by the author at the Construction Chemicals International Conference 2012 held in Mumbai)

You may like

Concrete

Cement Additives for Improved Grinding Efficiency

Published

5 minutes agoon

February 20, 2026By

admin

Shreesh A Khadilkar discusses how advanced additive formulations allow customised, high-performance and niche cements—offering benefits while supporting blended cements and long-term cost and carbon reduction.

Cement additives are chemicals (inorganic and organic) added in small amounts (0.01 per cent to 0.2 per cent by weight) during cement grinding. Their main job? Reduce agglomeration, prevent pack-set, and keep the mill running smoother. Thus, these additions primarily improve, mill thru-puts, achieve lower clinker factor in blended cements PPC/PSC/PCC. Additionally, these additives improve concrete performance of cements or even for specific special premium cements with special USPs like lower setting times or for reduced water permeability in the resultant cement mortars and concrete (water repellent /permeation resistant cements), corrosion resistance etc.

The cement additives are materials which could be further differentiated as:

Grinding aids:

• Bottlenecks in cement grinding capacity, such materials can enhance throughputs

• Low specific electrical energy consumption during cement grinding

• Reduce “Pack set” problem and improve powder flowability

Quality improvers:

• Opportunity for further clinker factor reduction

• Solution for delayed cement setting or strength development issues at early or later ages.

Others: materials which are used for specific special cements with niche properties as discussed in the subsequent pages.

When cement additives are used as grinding aids or quality improvers, in general the additives reduce the inter-particle forces; reduce coating over grinding media and mill internals. Due to creation of like charges on cement particles, there is decreased agglomeration, much improved flowability, higher generation of fines better dispersion of particles in separator feed and reduction of mill filling level (decrease of residence time). However, in VRM grinding; actions need to be taken to have stable bed formation on the table.

It has been reported in literature and also substantiated by a number of detailed evaluations of different cement additive formulations in market, that the cement additive formulations are a combination of different chemical compounds, typically composed of:

- Accelerator/s for the hydration reaction of cements which are dependent on the acceleration effect desired in mortar compressive strengths at early or later ages, the choice of the materials is also dependent on clinker quality and blending components (flyash / slag) or a mix of both.

- Water reducer / workability / wet-ability enhancer, which would show impact on the resultant cement mortars and concrete. Some of the compounds (retarders) like polysaccharide derivatives, gluconates etc., show an initial retarding action towards hydration which result in reducing the water requirements for the cements thus act as water reducers, or it could be some appropriate polymeric molecules which show improved wet-ability and reduce water demand. These are selected based on the mineral component and type of cements (PPC/PSC /PCC).

- Grinding aids: Compounds that work as Grinding Aid i.e. which would enhance Mill thru-put on one hand as well as would increase the early strengths due to the higher fines generation/ or activation of cement components. These compounds could be like alkanol-amines such as TIPA, DEIPA, TEA etc. or could be compounds like glycols and other poly-ols, depending on whether it is OPC or PPC or PSC or PCC manufacture.

Mechanism of action — Step By Step—

- Reduce Agglomeration, Cement particles get electrostatically charged during grinding, stick together, form “flocs”, block mill efficiency, waste energy. Grinding aid molecules adsorb onto particle surfaces, neutralise charge, prevent re-agglomeration.

- Improve Powder Flowability, Adsorbed molecules create a lubricating layer, particles slide past each other easier, better mill throughput, less “dead zone” buildup.

Also reduces caking on mill liners, diaphragms, and separator screens, less downtime for cleaning. - Enhance Grinding Efficiency (Finer Product Faster), By preventing agglomeration, particles stay dispersed more surface area exposed to grinding media, finer grind achieved with same energy input, Or: same fineness achieved with less energy, huge savings.

Example:

• Without aid ? 3500 cm²/g Blaine needs 40 kWh/ton

• With use of optimum grinding aid same fineness at 32 kWh/ton 20 per cent energy savings - Reduce Pack Set and Silo Caking Grinding aids (GA) inhibit hydration of free lime (CaO) during storage prevents premature hardening or “pack set” in silos. especially critical in humid climates or with high free lime clinker.

It may be stated here that Overdosing of GA can cause: – Foaming in mill (especially with glycols) reduces grinding efficiency, retardation of cement setting (especially with amines/acids), odor issues (in indoor mills) – Corrosion of mill components (if acidic aids used improperly)

The best practice to optimise use of GA is Start with 0.02 per cent to 0.05 per cent dosage test fineness, flow, and set time adjust up/down. Due to static charge of particles, the sample may stick to the sides of sampler pipe and so sampling need to be properly done.

Depending on type of cements i.e. OPC, PPC, PSC, PCC, the grinding aids combinations need to be optimised, a typical Poly carboxylate ether also could be a part of the combo grinding aids

Cement additives for niche properties of the cement in concrete.

The cement additives can also be tailor made to create specific niche properties in cements, OPC, PPC, PSC and PCC to create premium or special brands. The special niche properties of the cement being its additional USP of such cement products, and are useful for customers to build a durable concrete structure with increased service life.

Such properties could be:

• Additives for improved concrete performance of cements, high early strength in PPC/PSC/PCC, much reduced water demand in cement, cements with improved slump retentivity in concrete, self-compacting, self levelling in concrete, cements with improved adhesion property of the cement mortar

• Water repellence / water proofing, permeability resistance in mortars and concrete.

• Biocidal cement

• Photo catalytic cements

• Cements with negligible ASR reactions etc.

Additives for cements for improved concrete performance

High early strengths: Use of accelerators. These are chemical compounds which enhance the degree of hydration of cement. These can include setting or hardening accelerators depending on whether their action occurs in the plastic or hardened state respectively. Thus, the setting accelerators reduce the setting time, whereas the hardening accelerators increase the early age strengths. The setting accelerators act during the initial minutes of the cement hydration, whereas the hardening accelerators act mainly during the initial days of hydration.

Chloride salts are the best in class. However, use of chloride salts as hardening accelerators are strongly discouraged for their action in promoting the corrosion of rebar, thus, chloride-free accelerators are preferred. The hardening accelerators could be combinations of compounds like nitrate, nitrite and thiocyanate salts of alkali or alkaline earth metals or thiosulphate, formate, and alkanol amines depending on the cement types.

However, especially in blended cements (PPC/PSC/PCC the increased early strengths invariably decrease the 28 day strengths. These aspects lead to creating combo additives along with organic polymers to achieve improved early strengths as well as either same or marginally improved 28 days strengths with reduced clinker factor in the blended cement, special OPC with reduced admixture requirements. With use of appropriate combination of inorganic and organic additives we could create an OPC with substantially reduced water demand or improved slump retentivity. Use of such an OPC would show exceptional concrete performance in high grade concretes as it would exhibit lower admixture requirements in High Grade Concretes.

PPC with OPC like properties: With the above concept we could have a PPC, having higher percentage flyash, with a combo cement additive which would have with concrete performance similar to OPC in say M40/M50 concrete. Such a PPC would produce a high-strength PPC concrete (= 60 MPa @ 28d) + improved workability, durability and sustainability.

Another interesting aspect could also be of using ultrafine fine flyash /ultrafine slags as additions in OPC/PPC/PSC for achieving lower clinker factor as well as to achieve improved later age strengths with or without a combo cement additive.

The initial adhesion property at sites of especially PPC/PSC/PCC based mortars can be improved through use of appropriate organic polymers addition during the manufacture of these cements. Such cements would have a better adhesion property for plastering/brick bonding etc., as it has much lower rebound loss of their mortars in such applications.

It is needless to mention here that with use of additives, we could also have cement with viscosity modifying cement additives, for self-compaction and self-leveling concrete performance.

Use of Phosphogypsum retards the setting time of cements, we can use additive different additive combos to overcome retardation and improve the 1 day strengths of the cements and concretes.

About the author:

Shreesh Khadilkar, Consultant & Advisor, Former Director Quality & Product Development, ACC, a seasoned consultant and advisor, brings over 37 years of experience in cement manufacturing, having held leadership roles in R&D and product development at ACC Ltd. With deep expertise in innovative cement concepts, he is dedicated to sharing his knowledge and improving the performance of cement plants globally.

Concrete

Digital Pathways for Sustainable Manufacturing

Published

31 minutes agoon

February 20, 2026By

admin

Dr Y Chandri Naidu, Chief Technology Officer, Nextcem Consulting highlights how digital technologies are enabling Indian cement plants to improve efficiency, reduce emissions, and transition toward sustainable, low-carbon manufacturing.

Cement manufacturing is inherently resource- and energy-intensive due to high-temperature clinkerisation and extensive material handling and grinding operations. In India, where cement demand continues to grow in line with infrastructure development, producers must balance capacity expansion with sustainability commitments. Energy costs constitute a major share of operating expenditure, while process-related carbon dioxide emissions from limestone calcination remain unavoidable.

Traditional optimisation approaches, which are largely dependent on operator experience, static control logic and offline laboratory analysis, have reached their practical limits. This is especially evident when higher levels of alternative fuel and raw materials (AFR) are introduced or when raw material variability increases.

Digital technologies provide a systematic pathway to manage this complexity by enabling

real-time monitoring, predictive optimisation and integrated decision-making across cement manufacturing operations.

Digital cement manufacturing is enabled through a layered architecture integrating operational technology (OT) and information technology (IT). At the base are plant instrumentation, analysers, and automation systems, which generate continuous process data. This data is contextualised and analysed using advanced analytics and AI platforms, enabling predictive and prescriptive insights for operators and management.

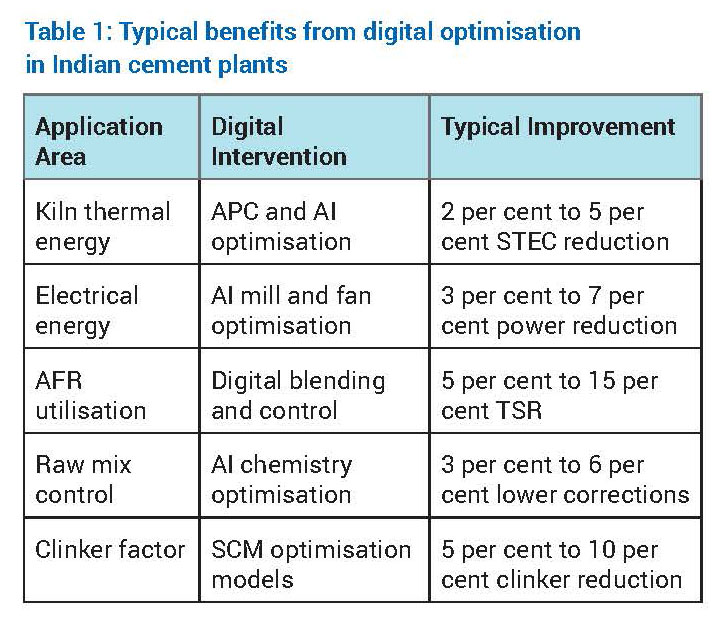

Digital optimisation of energy efficiency

- Thermal energy optimisation

The kiln and calciner system accounts for approximately 60 per cent to 65 per cent of total energy consumption in an integrated cement plant. Digital optimisation focuses on reducing specific thermal energy consumption (STEC) while maintaining clinker quality and operational stability.

Advanced Process Control (APC) stabilises critical parameters such as burning zone temperature, oxygen concentration, kiln feed rate and calciner residence time. By minimising process variability, APC reduces the need for conservative over-firing. Artificial intelligence further enhances optimisation by learning nonlinear relationships between raw mix chemistry, AFR characteristics, flame dynamics and heat consumption.

Digital twins of kiln systems allow engineers to simulate operational scenarios such as increased AFR substitution, altered burner momentum or changes in raw mix burnability without operational risk. Indian cement plants adopting these solutions typically report STEC reductions in the range of 2 per cent to 5 per cent. - Electrical energy optimisation

Electrical energy consumption in cement plants is dominated by grinding systems, fans and material transport equipment. Machine learning–based optimisation continuously adjusts mill parameters such as separator speed, grinding pressure and feed rate to minimise specific power consumption while maintaining product fineness.

Predictive maintenance analytics identify inefficiencies caused by wear, fouling or imbalance in fans and motors. Plants implementing plant-wide electrical energy optimisation typically achieve

3 per cent to 7 per cent reduction in specific power consumption, contributing to both cost savings and indirect CO2 reduction.

Digital enablement of AFR

AFR challenges in the Indian context: Indian cement plants increasingly utilise biomass, refuse-derived fuel (RDF), plastic waste and industrial by-products. However, variability in calorific value, moisture, particle size, chlorine and sulphur content introduces combustion instability, build-up formation and emission risks.

Digital AFR management: Digital platforms integrate real-time AFR quality data from online analysers with historical kiln performance data. Machine learning models predict combustion behaviour, flame stability and emission trends for different AFR combinations. Based on these predictions, fuel feed distribution, primary and secondary air ratios, and burner momentum are dynamically adjusted to ensure stable kiln operation. Digitally enabled AFR management in cement plants will result in increased thermal substitution rates by 5-15 percentage points, reduced fossil fuel dependency, and improved kiln stability.

Digital resource and raw material optimisation

Raw mix control: Raw material variability directly affects kiln operation and clinker quality. AI-driven raw mix optimisation systems continuously adjust feed proportions to maintain target chemical parameters such as Lime Saturation Factor (LSF), Silica Modulus (SM), and Alumina Modulus (AM). This reduces corrective material usage and improves kiln thermal efficiency.

Clinker factor reduction: Reducing clinker factor through supplementary cementitious materials (SCMs) such as fly ash, slag and calcined clay is a key decarbonisation lever. Digital models simulate blended cement performance, enabling optimisation of SCM proportions while maintaining strength and durability requirements.

Challenges and strategies for digital adoption

Key challenges in Indian cement plants include data quality limitations due to legacy instrumentation, resistance to algorithm-based decision-making, integration complexity across multiple OEM systems, and site-specific variability in raw materials and fuels.

Successful digital transformation requires strengthening the data foundation, prioritising high-impact use cases such as kiln APC and energy optimisation, adopting a human-in-the-loop approach, and deploying modular, scalable digital platforms with cybersecurity by design.

Future Outlook

Future digital cement plants will evolve toward autonomous optimisation, real-time carbon intensity tracking, and integration with emerging decarbonisation technologies such as carbon capture, utilisation and storage (CCUS). Digital platforms will also support ESG reporting and regulatory compliance.

Digital pathways offer a practical and scalable solution for sustainable cement manufacturing in India. By optimising energy consumption, enabling higher AFR substitution and improving resource efficiency, digital technologies deliver measurable environmental and economic benefits. With appropriate data infrastructure, organisational alignment and phased implementation, digital transformation will remain central to the Indian cement industry’s low-carbon transition.

About the author:

Dr Y Chandri Naidu is a cement industry professional with 30+ years of experience in process optimisation, quality control and quality assistance, energy conservation and sustainable manufacturing, across leading organisations including NCB, Ramco, Prism, Ultratech, HIL, NCL and Vedanta. He is known for guiding teams, developing innovative plant solutions and promoting environmentally responsible cement production. He is also passionate about mentoring professionals and advancing durable, resource efficient technologies for future of construction materials.

Concrete

Our strategy is to establish reliable local partnerships

Published

19 hours agoon

February 19, 2026By

admin

Jean-Jacques Bois, President, Nanolike, discusses how real-time data is reshaping cement delivery planning and fleet performance.

As cement producers look to extract efficiency gains beyond the plant gate, real-time visibility and data-driven logistics are becoming critical levers of competitiveness. In this interview with Jean-Jacques Bois, President, Nanolike, we discover how the company is helping cement brands optimise delivery planning by digitally connecting RMC silos, improving fleet utilisation and reducing overall logistics costs.

How does SiloConnect enable cement plants to optimise delivery planning and logistics in real time?

In simple terms, SiloConnect is a solution developed to help cement suppliers optimise their logistics by connecting RMC silos in real time, ensuring that the right cement is delivered at the right time and to the right location. The core objective is to provide real-time visibility of silo levels at RMC plants, allowing cement producers to better plan deliveries.

SiloConnect connects all the silos of RMC plants in real time and transmits this data remotely to the logistics teams of cement suppliers. With this information, they can decide when to dispatch trucks, how to prioritise customers, and how to optimise fleet utilisation. The biggest savings we see today are in logistics efficiency. Our customers are able to sell and ship more cement using the same fleet. This is achieved by increasing truck rotation, optimising delivery routes, and ultimately delivering the same volumes at a lower overall logistics cost.

Additionally, SiloConnect is designed as an open platform. It offers multiple connectors that allow data to be transmitted directly to third-party ERP systems. For example, it can integrate seamlessly with SAP or other major ERP platforms, enabling automatic order creation whenever replenishment is required.

How does your non-exclusive sensor design perform in the dusty, high-temperature, and harsh operating conditions typical of cement plants?

Harsh operating conditions such as high temperatures, heavy dust, extreme cold in some regions, and even heavy rainfall are all factored into the product design. These environmental challenges are considered from the very beginning of the development process.

Today, we have thousands of sensors operating reliably across a wide range of geographies, from northern Canada to Latin America, as well as in regions with heavy rainfall and extremely high temperatures, such as southern Europe. This extensive field experience demonstrates that, by design, the SiloConnect solution is highly robust and well-suited for demanding cement plant environments.

Have you initiated any pilot projects in India, and what outcomes do you expect from them?

We are at the very early stages of introducing SiloConnect in India. Recently, we installed our

first sensor at an RMC plant in collaboration with FDC Concrete, marking our initial entry into the Indian market.

In parallel, we are in discussions with a leading cement producer in India to potentially launch a pilot project within the next three months. The goal of these pilots is to demonstrate real-time visibility, logistics optimisation and measurable efficiency gains, paving the way for broader adoption across the industry.

What are your long-term plans and strategic approach for working with Indian cement manufacturers?

For India, our strategy is to establish strong and reliable local partnerships, which will allow us to scale the technology effectively. We believe that on-site service, local presence, and customer support are critical to delivering long-term value to cement producers.

Ideally, our plan is to establish an Indian entity within the next 24 months. This will enable us to serve customers more closely, provide faster support and contribute meaningfully to the digital transformation of logistics and supply chain management in the Indian cement industry.

Cement Additives for Improved Grinding Efficiency

Digital Pathways for Sustainable Manufacturing

Our strategy is to establish reliable local partnerships

Power Build’s Core Gear Series

Compliance and growth go hand in h and

Cement Additives for Improved Grinding Efficiency

Digital Pathways for Sustainable Manufacturing

Our strategy is to establish reliable local partnerships

Power Build’s Core Gear Series