Product development

The Opportunity in Water

Published

5 years agoon

By

admin

Taking a three-pronged approach, ACF commenced work to better equip the community with the resources to deal with the harsh climatic conditions ??working closely with the local people there to drive harvesting of water and groundwater recharge, creating year-round access to drinking water and promoting the judicious use of water within the community, particularly in the ??hirsty??agricultural sector, writes Pearl Tiwari of ACF.

Cement and other manufacturing companies often get a bad rap for being big consumers of water ??criticised for their consumption, and for the resulting negative impact they have on local community water resources.

But Ambuja Cements has managed to do exactly the opposite and in 2019 was an eight times water positive company ??a result of an emphasis on initiatives to both conserve water in plant operations and harvest water in communities ??eyond the fence??

Nowhere are the outcomes of this more dramatically seen, than in Rabriyawas, Rajasthan, where the once stark, arid landscape now flourishes with an abundant agricultural sector which generates prosperity for farmers, their families, and local economies.

How then, has the Indian cement giant managed to transform the region and harness the power of water as an opportunity not only for the company, but for the broader Rabriyawas region and the 63,000 people who live there?

??utside the Fence??Investment

When Ambuja Cement?? founder, Narotam Sekhsaria, took the first steps to kickstart the company in 1986, he decided to start investing in the local communities that surrounded the plant site ??in fact even before the plant itself had come up. A visionary, he knew that it was of vital importance for the community to grow and flourish alongside the company – not only would it provide licence to operate, but it would support the company?? long term sustainability agenda, build the reputation in the community as a responsible company and generate lots of goodwill along the way.

So when ACL mooted a plant in Rabriyawas in 2002, Ambuja Cement Foundation (ACF)??he company?? CSR arm??obilised to conduct a needs assessment of the area to generate ??utside the fence??strategies, and there were no surprises when water emerged as the most pressing need of the hour.

Located on the edge of the Thar Desert in Rajasthan, Rabriyawas is home to a particularly hostile climate with temperatures often skyrocketing above 50 degrees Celsius; erratic and often deficit rainfall sees the region face harsh drought every four to five years; and famine hits the region once every 50 years, causing mass migration. Despite the fragile ecosystem, acute drinking water scarcity and vulnerable livelihoods, it is still the most densely populated desert in India.

Taking a three-pronged approach, ACF commenced work to better equip the community with the resources to deal with the harsh climatic conditions ??working closely with the local people there to drive harvesting of water and groundwater recharge, creating year-round access to drinking water and promoting the judicious use of water within the community, particularly in the ??hirsty??agricultural sector. Blending both traditional techniques and modern technologies in their approach, ACF rolled up its sleeves and got to work.

Rainwater harvesting & groundwater recharge

One of the most ancient and traditional structures for rainwater harvesting in the dry desert state are ponds. In Rajasthan, it is estimated that there are about 83,000 ponds. However, the changing social milieu has meant that many of these water bodies have fallen into disrepair due to improper maintenance and the advent of modern forms of water supply. Across communities, ponds seep water, have become polluted and are full of silt, which has reduced the quality and volume of water available in ponds.

In 2003-04, ACF decided to start their work by reviving four ponds in Rabriyawas, Pali district, with the idea of making the project sustainable by involving the local community to ensure ??hey embrace and manage each pond for future generations??

Work started with the local community of Balada (Pali district) where ACF committed to the supply of machinery for de-silting of ponds. The huge manpower and transportation required for the removal of silt from the site however, was provided by the community. This soil was high in nutrients and provided a great resource to add topsoil to farmer fields and build farm bunds to trap and channel water.

Together they revived the ponds, resulting in an additional 1,25,800 cubic meters water storage capacity in Balada through multiple times deepening in the past 15 years. And the ripple effect in the community was unbelievable. Farmers were able to bring 120 acres more land under cultivation, 80 wells near the Balada pond were recharged and soil fertility improved. There was a 66 per cent decrease in dependency on piped water and 57 per cent decrease in tanker water resulting in a shift of water source especially for drinking purposes. Expenditure on water reduced 14 per cent and expenditure on health reduced by 22 per cent. And this was just the beginning.

As time passed and work scaled up, ACF has worked with communities in a similar fashion and a total of 191 village ponds have been deepened for increasing their storage capacity in the last 15 years. Of course, this was not the only intervention and a variety of other harvesting strategies were adopted, including construction of 35 khadins, 47 farm ponds, 44 check dams, one earthen dam and the widespread promotion of Roof Rainwater Harvesting Structure (RRWHS) at household and community level.

The beauty of water harvesting is that it not only captures rain as it falls for community use, but it also recharges the ground water aquifers as well ??vital to an area like Rabriyawas. According to the Central Ground Water guidelines, Rabriyawas falls under the ??ark zone??category ??one of the most serious as far as ground water availability is concerned. With no major surface water bodies like rivers lakes or canals in the area, groundwater was the principal source to fulfil demand for domestic, agriculture and industrial purposes in Rabriyawas.

With this scenario in place, ACL was concerned about water sustainability and knew it had to look well beyond its own fence and work with the entire area around its manufacturing plant to ensure an increase in the water table.

So, the recharge of groundwater became a key strategy for ACF in its efforts to transform the area and was value added by building a series of 17 subsurface dykes (subsurface barriers in sandy riverbeds.)

Subsurface dykes are a unique feature of the project area in Pali district and are an example of groundwater conservation technique for rivers having sandy beds in the arid and semi-arid regions of Rajasthan. The success story of the sub-surface dykes has demonstrated that it is one of the most feasible methods for the conservation and exploitation of the ground water resources.

Drinking water

With the average rate of depletion of the groundwater table in the Pali district more than 0.4 m per year, the over abstraction of groundwater had led to severe problems in the quality of water with a high presence of fluoride and salinity ??making it unfit for human consumption. Between 1996 and 2001, the number of villages suffering due to poor quality of drinking water in Pali went up from 13.3 per cent to 66.2 per cent.

ACF started to monitor groundwater quality to track changes due to the extensive work done on water harvesting and groundwater recharge. In 2010, total dissolvable solids were 2992 but by 2018, TDS had reduced to 808.

Meanwhile, ACF set a target to ensure water sufficiency for each household in core villages in Rabriyawas and set about supporting 2690 families for the construction of RRWHS (average capacity of 12,000 litres) in the area to meet the potable water requirements at household level. The tanks were enough to meet the year-round requirement of families in the area and had a dramatic impact on health indicators. For example, there was a reduction in the prevalence of fluoride and kidney stones among the population and 98.04 per cent of beneficiaries highlighted a positive influence on their health, due to improvements in drinking water quality.

Improving water use efficiency in agriculture

A key issue that needed to be addressed was the inefficient use of water in the area, particularly within the agricultural sector, as water demand management is vital in order for local people to manage and conserve the water they have available. The productivity of water is improved through the promotion of water efficient irrigation methods and by creating awareness among farmers of necessary behaviour change.

ACF?? approach was to demonstrate the use of micro irrigation (drip and sprinkler systems) and promote its benefits. This was necessary as the adoption of this technology requires a significant investment by farmers. Slowly as a few farmers came forward to adopt it, others witnessed the resultant increase in yield, saving of water, reduced energy consumption, and reduced labour requirement and cost, and followed suit. Over time, a total of 510 farmers have adopted micro irrigation saving 2.78 million cubic meters (mcm) of water in the process.

Today there is an increase in crop intensity from a single crop per year, to double and triple crops by using micro irrigation and farm ponds. Once barren land has been transformed thanks to irrigation and soil treatment and is now being utilised by farmers. About 97 per cent of farmers have increased crop yields due to the availability of water.

Community impacts

In Rabriyawas, with a total investment of Rs 8.2 crore over 15 years of work, ACF has impacted 65,000 people, increased groundwater levels by 2 to 12 m, and generated over 16.33 mcm additional water storage. Water availability at household level reduced women drudgery and saved time with a value ranging from one to four hours per day in the project area.

Additionally, an independent study indicated a five times social return on every rupee invested in water resource management in Rabriyawas, as the ripple effect of water generated positive impacts on other areas of community life like health, education, and employment.

??nside the Fence??strategies

Although ACL uses a dry process of cement production which uses minimal water, water conservation and its sustainability remains on a high pedestal in the company?? overall Sustainable Development plan with aspirational targets for 2030.

??nside of the fence??at Rabriyawas, ACL employs many strategies to recycle, reuse and reduce its use of water in its operations. Several water efficiency measures have been put in place, like the installation of waste heat recovery, roller press, dip tube in lower stage cyclone, raw water storage tank (10,000 KL), and air cooled air compressors and dryers. The plant recycles about 70,000 cubic meters of water (14 per cent of water withdrawal) which is helping the plant to reduce its overall water withdrawal.

On site there is a revival of water harvesting which saw the connection of water-logged area to main drainage lines. There is also a sewage treatment plant installed and all the waste water discharged from the plant and colonies are directed to this treatment plant, which in turn is used for horticulture purposes in the plant areas.

Even the employees have gotten involved. Work is being done to motivate and reward employees for playing a role in water conservation and there is a number of water awareness campaigns run throughout the year at the plant and in the Ambuja colonies. A water management committee was formed which takes care of the level of water used, efficiency and conservation. Frequent water talks and seminars are organised for the employees and a ??ater Hero Award??is granted every year to that department who has made sufficient efforts to reduce the use of water for its work in the plant. World Water Day is also celebrated at the plant.

The culmination of all these strategies has made the Rabriyawas plant one of the most efficient plants at Ambuja Cements and today it is almost 34 times water positive.

Of course much more is being done at a national level within the company, and innovative products and services have been developed to reduce the consumption of water at customer end. Modular curing solutions (MCS) is a unique curing application which does not require extra water flooding after roof slab casting for curing. MCS enhances the hydration process by preventing moisture evaporation from concrete and thus typically saves about 12,000 litres of water in curing 1,000 square feet of slab surface.

In 2019, ACL across locations, enabled customers for water saving of around 223 million litres at the customer front where its Technical Services team provided water optimisation in concrete mix proportions at 43433 sites (saving about 54 million litres of water onsite), modular curing solutions (MCS) at 7,714 sites (saving about 93 million litres of water onsite) and rain water harvesting (RWH) solutions at 893 sites (harvesting about 76 million litres of rain water). These were construction sites on the customer side of the supply chain in many parts of the country where often water availability and quality were a challenge.

Conclusion

Water is a critical need for most regions in India and has emerged as a single common agenda among several locations where Ambuja Cements has spread its wings over the last two decades. As a shared resource locally, this lever creates business value by leveraging strategic social investment to address water related risks in the community around plant operations. By harnessing both inside and outside the fence strategies, ACF has developed a significant water positive status, which continues to grow year after year.

The work by ACF in Rabriyawas is just one example of how that opportunity presents a win-win for all stakeholders and its success was integral to the awarding of the Jal Shakti Ministry?? annual National Water Mission Awards under the category ??ocused attention to vulnerable areas including over-exploited areas??to ACF in 2019.

It also highlights how, by tackling this important issue and optimising water for both business and community, today and for the future, water presents an exciting opportunity to industries that rely on it as a core resource for their business.

ABOUT THE AUTHOR:

Pearl Tiwari, Director & CEO, Ambuja Cement Foundation. Tiwari is a social development professional having worked in this area across diverse academic, NGO and CSR roles. A post-graduate from Tata Institute of Social Sciences (TISS) with 37 years of experience in the development sector.

You may like

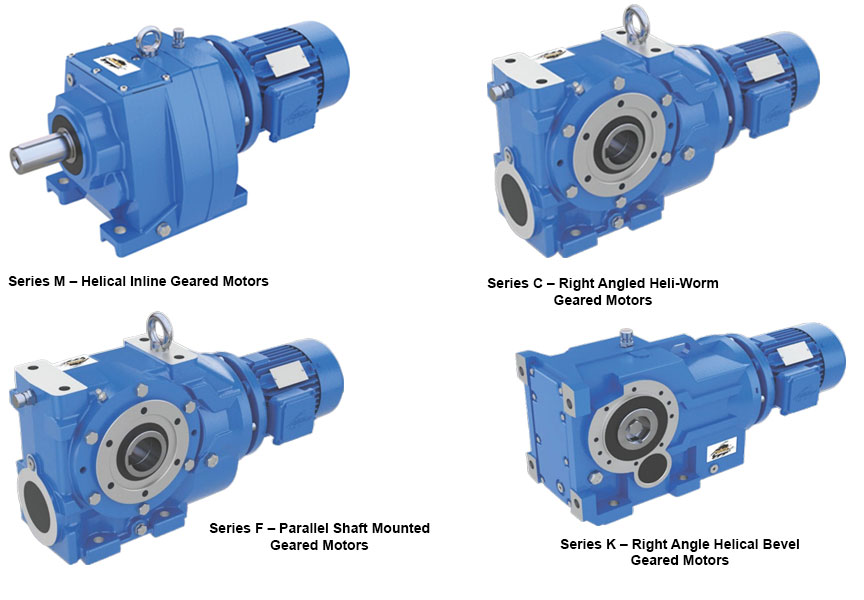

A deep dive into Core Gear Series of products M, C, F and K, by Power Build, and how they represent precision in motion.

At the heart of every high-performance industrial system lies the need for robust, reliable, and efficient power transmission. Power Build answers this need with its flagship geared motor series: M, C, F and K. Each series is meticulously engineered to serve specific operational demands while maintaining the universal promise of durability, efficiency, and performance.

Series M – Helical Inline Geared Motors

Compact and powerful, the Series M delivers exceptional drive solutions for a broad range of applications. With power handling up to 160kW and torque capacity reaching 20,000 Nm, it is the trusted solution for industries requiring quiet operation, high efficiency, and space-saving design. Series M is available with multiple mounting and motor options, making it a versatile choice for manufacturers and OEMs globally.

Series C – Right Angled Heli-Worm Geared Motors

Combining the benefits of helical and worm gearing, the Series C is designed for right-angled power transmission. With gear ratios of up to 16,000:1 and torque capacities of up to 10,000 Nm, this series is optimal for applications demanding precision in compact spaces. Industries looking for a smooth, low-noise operation with maximum torque efficiency rely on Series C for dependable performance.

Series F – Parallel Shaft Mounted Geared Motors

Built for endurance in the most demanding environments, Series F is widely adopted in steel plants, hoists, cranes and heavy-duty conveyors. Offering torque up to 10,000 Nm and high gear ratios up to 20,000:1, this product features an integral torque arm and diverse output configurations to meet industry-specific challenges head-on.

Series K – Right Angle Helical Bevel Geared Motors

For industries seeking high efficiency and torque-heavy performance, Series K is the answer. This right-angled geared motor series delivers torque up to 50,000 Nm, making it a preferred choice in core infrastructure sectors such as cement, power, mining and material handling. Its flexibility in mounting and broad motor options offer engineers the freedom in design and reliability in execution.

Together, these four series reflect Power Build’s commitment to excellence in mechanical power transmission. From compact inline designs to robust right-angle drives, each geared motor is a result of decades of engineering innovation, customer-focused design and field-tested reliability. Whether the requirement is speed control, torque multiplication or space efficiency, Radicon’s Series M, C, F and K stand as trusted powerhouses for global industries.

http://www.powerbuild.in

Call: +919727719344

Economy & Market

Conveyor belts are a vital link in the supply chain

Published

8 months agoon

June 16, 2025By

admin

Kamlesh Jain, Managing Director, Elastocon, discusses how the brand delivers high-performance, customised conveyor belt solutions for demanding industries like cement, mining, and logistics, while embracing innovation, automation, and sustainability.

In today’s rapidly evolving industrial landscape, efficient material handling isn’t just a necessity—it’s a competitive advantage. As industries such as mining, cement, steel and logistics push for higher productivity, automation, and sustainability, the humble conveyor belt has taken on a mission-critical role. In this exclusive interview, Kamlesh Jain, Managing Director, Elastocon, discusses how the company is innovating for tougher terrains, smarter systems and a greener tomorrow.

Brief us about your company – in terms of its offerings, manufacturing facilities, and the key end-user industries it serves.

Elastocon, a flagship brand of the Royal Group, is a trusted name in the conveyor belt manufacturing industry. Under the brand name ELASTOCON, the company produces both open-end and endless belts, offering tailor-made solutions to some of the most demanding sectors such as cement, steel, power, mining, fertiliser, and logistics. Every belt is meticulously engineered—from fabric selection to material composition—to ensure optimal performance in tough working conditions. With advanced manufacturing facilities and strict quality protocols, Elastocon continues to deliver high-performance conveyor solutions designed for durability, safety, and efficiency.

How is the group addressing the needs for efficient material handling?

Efficient material handling is the backbone of any industrial operation. At Elastocon, our engineering philosophy revolves around creating belts that deliver consistent performance, long operational life, and minimal maintenance. We focus on key performance parameters such as tensile strength, abrasion resistance, tear strength, and low elongation at working tension. Our belts are designed to offer superior bonding between plies and covers, which directly impacts their life and reliability. We also support clients

with maintenance manuals and technical advice, helping them improve their system’s productivity and reduce downtime.

How critical are conveyor belts in ensuring seamless material handling?

Conveyor belts are a vital link in the supply chain across industries. In sectors like mining, cement, steel, and logistics, they facilitate the efficient movement of materials and help maintain uninterrupted production flows. At Elastocon, we recognise the crucial role of belts in minimising breakdowns and increasing plant uptime. Our belts are built to endure abrasive, high-temperature, or high-load environments. We also advocate proper system maintenance, including correct belt storage, jointing, roller alignment, and idler checks, to ensure smooth and centered belt movement, reducing operational interruptions.

What are the key market and demand drivers for the conveyor belt industry?

The growth of the conveyor belt industry is closely tied to infrastructure development, increased automation, and the push for higher operational efficiency. As industries strive to reduce labor dependency and improve productivity, there is a growing demand for advanced material handling systems. Customers today seek not just reliability, but also cost-effectiveness and technical superiority in the belts they choose. Enhanced product aesthetics and innovation in design are also becoming significant differentiators. These trends are pushing manufacturers to evolve continuously, and Elastocon is leading the way with customer-centric product development.

How does Elastocon address the diverse and evolving requirements of these sectors?

Our strength lies in offering a broad and technically advanced product portfolio that serves various industries. For general-purpose applications, our M24 and DINX/W grade belts offer excellent abrasion resistance, especially for RMHS and cement plants. For high-temperature operations, we provide HR and SHR T2 grade belts, as well as our flagship PYROCON and PYROKING belts, which can withstand extreme heat—up to 250°C continuous and even 400°C peak—thanks to advanced EPM polymers.

We also cater to sectors with specialised needs. For fire-prone environments like underground mining, we offer fire-resistant belts certified to IS 1891 Part V, ISO 340, and MSHA standards. Our OR-grade belts are designed for oil and chemical resistance, making them ideal for fertiliser and chemical industries. In high-moisture applications like food and agriculture, our MR-grade belts ensure optimal performance. This diverse range enables us to meet customer-specific challenges with precision and efficiency.

What core advantages does Elastocon offer that differentiate it from competitors?

Elastocon stands out due to its deep commitment to quality, innovation, and customer satisfaction. Every belt is customised to the client’s requirements, supported by a strong R&D foundation that keeps us aligned with global standards and trends. Our customer support doesn’t end at product delivery—we provide ongoing technical assistance and after-sales service that help clients maximise the value of their investments. Moreover, our focus on compliance and certifications ensures our belts meet stringent national and international safety and performance standards, giving customers added confidence.

How is Elastocon gearing up to meet its customers’ evolving needs?

We are conscious of the shift towards greener and smarter manufacturing practices. Elastocon is embracing sustainability by incorporating eco-friendly materials and energy-efficient manufacturing techniques. In parallel, we are developing belts that seamlessly integrate with automated systems and smart industrial platforms. Our vision is to make our products not just high-performing but also future-ready—aligned with global sustainability goals and compatible with emerging technologies in industrial automation and predictive maintenance.

What trends do you foresee shaping the future of the conveyor belt industry?

The conveyor belt industry is undergoing a significant transformation. As Industry 4.0 principles gain traction, we expect to see widespread adoption of smart belts equipped with sensors for real-time monitoring, diagnostics, and predictive maintenance. The demand for recyclable materials and sustainable designs will continue to grow. Furthermore, industry-specific customisation will increasingly replace standardisation, and belts will be expected to do more than just transport material—they will be integrated into intelligent production systems. Elastocon is already investing in these future-focused areas to stay ahead of the curve.

Advertising or branding is never about driving sales. It’s about creating brand awareness and recall. It’s about conveying the core values of your brand to your consumers. In this context, why is branding important for cement companies? As far as the customers are concerned cement is simply cement. It is precisely for this reason that branding, marketing and advertising of cement becomes crucial. Since the customer is unable to differentiate between the shades of grey, the onus of creating this awareness is carried by the brands. That explains the heavy marketing budgets, celebrity-centric commercials, emotion-invoking taglines and campaigns enunciating the many benefits of their offerings.

Marketing strategies of cement companies have undergone gradual transformation owing to the change in consumer behaviour. While TV commercials are high on humour and emotions to establish a fast connect with the customer, social media campaigns are focussed more on capturing the consumer’s attention in an over-crowded virtual world. Branding for cement companies has become a holistic growth strategy with quantifiable results. This has made brands opt for a mix package of traditional and new-age tools, such as social media. However, the hero of every marketing communication is the message, which encapsulates the unique selling points of the product. That after all is crux of the matter here.

While cement companies are effectively using marketing tools to reach out to the consumers, they need to strengthen the four Cs of the branding process – Consumer, Cost, Communication and Convenience. Putting up the right message, at the right time and at the right place for the right kind of customer demographic is of utmost importance in the long run. It is precisely for this reason that regional players are likely to have an upper hand as they rely on local language and cultural references to drive home the point. But modern marketing and branding domain is exponentially growing and it would be an interesting exercise to tabulate and analyse its impact on branding for cement.

Our strategy is to establish reliable local partnerships

Power Build’s Core Gear Series

Compliance and growth go hand in h and

Turning Downtime into Actionable Intelligence

FORNNAX Appoints Dieter Jerschl as Sales Partner for Central Europe

Our strategy is to establish reliable local partnerships

Power Build’s Core Gear Series

Compliance and growth go hand in h and

Turning Downtime into Actionable Intelligence