Product development

Wheels of automation picking up pace

Published

6 years agoon

By

admin

For the cement industry, it is imperative to adapt ways to address the key challenges of energy saving, water conservation, reduction in carbon dioxide and greenhouse gas emissions, and material resource and waste management. The question is how does one address this? An answer to this is process control automation, and major players in India’s cement sector feel the same.

Steel and cement are the two most critical elements of the construction industry. Any movement in these two components can have a direct impact on the infrastructure and economy of the country. Currently, India is the second largest cement producer in the world with a production capacity of more than 500 million tonne per annum (MTPA), and is expected to cross 550 MTPA by the end of 2020.

According to a projection in a report published by Research and Markets titled "Global Cement Market Insight, Trends and Forecast 2019-2021: Production, Consumption, Imports & Exports", the global cement consumption volume is expected to reach 4.42 billion tonnes in 2021, growing at a CAGR of 2.96 per cent during the period 2018-2021.

Increasing construction activities, rising urbanisation and higher disposable income are likely to be the growth drivers. However, the growth of the market would be challenged by depleting fossil fuel reserves. A few notable trends include expansion of civil engineering sector on a global scale, rising demand for green cement and increasing infrastructure projects in developing regions.

"The global cement industry is expanding in terms of production as well as consumption volume. The rising construction activities at a fast pace is promoting the cement demand considerably. The market demand for cement from civil engineering industry is rising strongly, due to the increasing investment by government on residential as well as public work sectors. This is enabling the cement manufacturers to produce cement on a large scale and thereby raising the consumption volume also," the report highlighted.

India: Still lagging

Though Indian exports cement to the international market, the country is far behind with $295.8 million, which is 2.9 per cent of the total international market. According to 2018 statistics, Vietnam led the pack with $1.1 billion (11.1 per cent of total cement exports). China is much ahead of India in ranking with more than double the share in its kitty. However, there is a bigger gap created by China with fewer exports, which can be filled by India if the companies increase their exports.

Cement as an industry is energy intense, highly raw material-driven, water intense, and has a higher environmental impact. Cement industry in India consumes 10 per cent of the total coal produced and 6 per cent of the total power consumed in the country. Typically, a cement plant consumes between 60-100 KW to produce one tonne of cement.

With the help of advanced technology the industry has been taking steps to control the environmental impact by adopting various measures. Reducing water intake by shifting from the previous wet process to the latest dry process, shifting of captive power from thermal (coal) to heat recovery as cement plants generate high temperature during the manufacturing process.

Change is happening

Cement factories are notorious for high greenhouse gas emissions. However, major players have been taking steps to mitigate the shortcomings and, to a large extent, have succeeded in their efforts by adopting various technologies.

For the industry, it is imperative to adapt ways to the address the key challenges of energy saving, water conservation, reduction in carbon dioxide and greenhouse gas emissions, material resource and waste management. The question is how does one address this? One-line answer to this is process control automation. The industry is in agreement that the cement industry requires faster changes to realise the set Vision 2030.

Here again, process control automation is seen with much apprehension: the disruption it creates, the cost factor, up-skilling of existing manpower, and the challenges of retrofitting.

Highlighting the solutions available for issues concerning cement plants these days, Rajat Kishore, Managing Director & Vice President- Process Automation India Hub, Schneider Electric India, points out, "In Schneider Electric, we have a specific initiative called "eco structure" for the cement industry. This helps plants to achieve greater efficiency with digitally-enabled solutions, through which energy monitoring and control solutions are provided. The solution also gives a transparent view of energy usage of productions both in the production process usage as well is in identifying potential savings. It also helps companies realise how automation is key to addressing the challenges of the cement industry."

Process control digitalisation

Cement industry in India has enormous opportunities for new investments. Plants are being set up, new captive plants are being done and the annual capacity is ever increasing. With a healthy pipeline of infrastructure development and hoisting sector in the offing, Indian cement industry is expected to gain momentum. To cater to the increasing demand, companies should also look at increasing efficiency in operations by automation.

The huge growth of infrastructure puts pressure on the cement manufacturers to become more and more efficient, and explore and attract entry of more international players to meet the competition. The fierce competition is driving the industry players to adopt automation. However, the key factor that would drive the automation process is the government regulations that stipulate strict compliance to reduction of greenhouse gas emissions.

Dwelling upon the digitalisation aspect vis-a-vis the cement industry, Mark Yseboodt, Sales Manager Automation – Minerals, Siemens AG, says, "Digitalisation is a very broad concept that can have various positive influences on a cement manufacturer’s costs, depending on the specific application in question."

Digital platform

He goes on to explain: "A simple logistics example is a digital platform where customers can place their order to the cement producer. The platform tells the customer and their truck driver where to find the nearest plant to pick up the order. The truck driver is identified with an RFID tag at the weighbridge at the entrance. The truck is guided to the right silo. He only has access to the silo that contains the type of cement that was ordered. The truck is loaded with the required amount of cement and leaves the plant through the weighbridge at the exit and an invoice is generated. Such a solution ensures that trucks are not loaded with the wrong cement type or quantity. Cement theft is avoided. An additional bonus is that by keeping track of the truck drivers and their behaviour, the plant can blacklist drivers that don’t respect the rules, thus improving the onsite safety."

When such simple technologies are available, what is preventing the cement industry from adapting to them, one wonders!

Rajat Kishore of Schneider adds, "The resistance to change invariably comes from the fear of how much you want to change. Take for instance, upscaling of manpower. Cement industry has a combination of skilled and unskilled manpower. The industry faces the challenge of finding suitably-trained manpower, especially equipped to handle newer technology. In my personal experience domestic cement players are increasingly adopting automation in process control. One will be surprised to know one of the technologies is called "digital road map". What is noticeable is that they are adopting our automation and energy-saving solutions. A tendency has been developed but things are moving at a slow pace. But change is not inevitable."

Next technology

Elaborating on the next level of technology, Yseboodt of Siemens says,"Remote access is becoming more and more the standard, resulting in the need for newly-killed people at cement plants. This has been going on for some years now. The main trend is the continued development of digitalisation solutions in various parts of the process. Basically, plant data is collected, transferred and stored so that it is available where and when it is required. We are seeing cases where additional data from the field is being used to improve the production process."

But is collection of data feasible and manageable? According to Yseboodt, data collection and management isn’t problematic at all!"Generating more data in itself is often not difficult. Simply, add another sensor. However, it is important to remember that most cement plants are running plants and there is often a limit to the amount of data that can be added to the control system. In fact, a lot of the data from the sensors is not necessarily required to control the process itself. Some data may only be relevant for maintenance purposes or for quality KPIs. In such cases, it is important not to overload the CPUs with irrelevant data," he says, adding: "The trend today is to create an additional data channel. Smart switches route the signals through the CPU and/or through the additional channel. In this way, you can add as much data as you want to your plant without (negatively) interfering with the existing automation system. The second data channel is designed to be fully secure and the data can be made available to selected users to see only what they need to see."

He further adds: "This new transparent layer of data analytics is gaining importance above the plant automation DCS, in which data is being quickly made available to customers on their machines and which help them to analyse and plan future course of action. Data analytics on plant data helps to define optimisation strategies as well as facilitate predictive maintenance."

According to Yseboodt,"Data analytics is paving the path for Artificial Intelligence (AI), a new technology that is finding its way into the cement industry. AI creates opportunities to solve issues that couldn’t be handled in the past. By collecting and archiving relevant data, it becomes possible to recognise patterns and detect anomalies that previously remained invisible. This allows the plant operators or the automation system to take corrective measures before an actual problem occurs."

Way forward

Smart Mining Platforms that can communicate with the machinery in the factory, support predictive assets maintenance on site, and support augmented reality, virtual reality and digital print. In the cement industry the objective is to achieve operational asset management excellence by increasing the readiness to leverage new age automation and deployment of integrated distant solutions. As AI and Machine Learning are taking their first steps into the cement industry, manufacturers are hopeful of a better management system at a reasonable cost.

– LIZA V

You may like

Economy & Market

Power Build’s Core Gear Series

Published

20 hours agoon

February 19, 2026By

admin

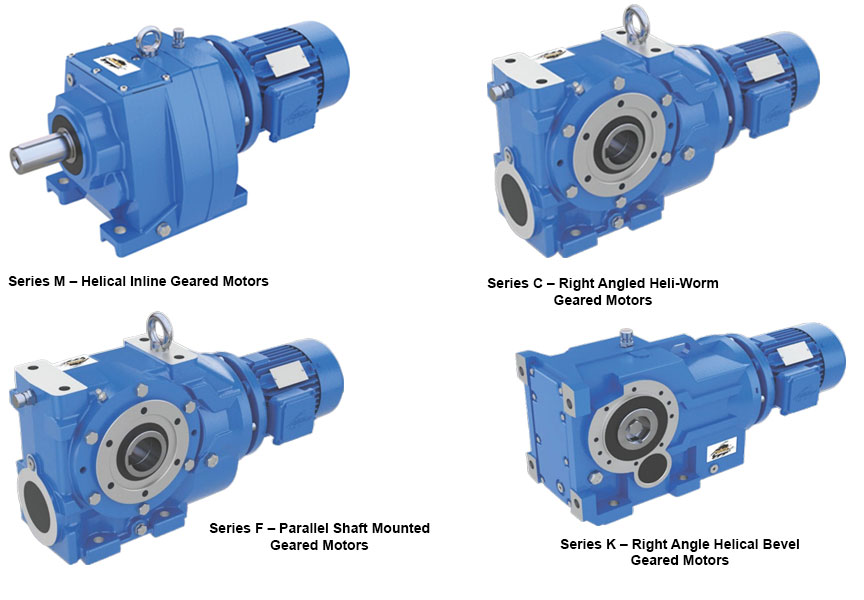

A deep dive into Core Gear Series of products M, C, F and K, by Power Build, and how they represent precision in motion.

At the heart of every high-performance industrial system lies the need for robust, reliable, and efficient power transmission. Power Build answers this need with its flagship geared motor series: M, C, F and K. Each series is meticulously engineered to serve specific operational demands while maintaining the universal promise of durability, efficiency, and performance.

Series M – Helical Inline Geared Motors

Compact and powerful, the Series M delivers exceptional drive solutions for a broad range of applications. With power handling up to 160kW and torque capacity reaching 20,000 Nm, it is the trusted solution for industries requiring quiet operation, high efficiency, and space-saving design. Series M is available with multiple mounting and motor options, making it a versatile choice for manufacturers and OEMs globally.

Series C – Right Angled Heli-Worm Geared Motors

Combining the benefits of helical and worm gearing, the Series C is designed for right-angled power transmission. With gear ratios of up to 16,000:1 and torque capacities of up to 10,000 Nm, this series is optimal for applications demanding precision in compact spaces. Industries looking for a smooth, low-noise operation with maximum torque efficiency rely on Series C for dependable performance.

Series F – Parallel Shaft Mounted Geared Motors

Built for endurance in the most demanding environments, Series F is widely adopted in steel plants, hoists, cranes and heavy-duty conveyors. Offering torque up to 10,000 Nm and high gear ratios up to 20,000:1, this product features an integral torque arm and diverse output configurations to meet industry-specific challenges head-on.

Series K – Right Angle Helical Bevel Geared Motors

For industries seeking high efficiency and torque-heavy performance, Series K is the answer. This right-angled geared motor series delivers torque up to 50,000 Nm, making it a preferred choice in core infrastructure sectors such as cement, power, mining and material handling. Its flexibility in mounting and broad motor options offer engineers the freedom in design and reliability in execution.

Together, these four series reflect Power Build’s commitment to excellence in mechanical power transmission. From compact inline designs to robust right-angle drives, each geared motor is a result of decades of engineering innovation, customer-focused design and field-tested reliability. Whether the requirement is speed control, torque multiplication or space efficiency, Radicon’s Series M, C, F and K stand as trusted powerhouses for global industries.

http://www.powerbuild.in

Call: +919727719344

Economy & Market

Conveyor belts are a vital link in the supply chain

Published

8 months agoon

June 16, 2025By

admin

Kamlesh Jain, Managing Director, Elastocon, discusses how the brand delivers high-performance, customised conveyor belt solutions for demanding industries like cement, mining, and logistics, while embracing innovation, automation, and sustainability.

In today’s rapidly evolving industrial landscape, efficient material handling isn’t just a necessity—it’s a competitive advantage. As industries such as mining, cement, steel and logistics push for higher productivity, automation, and sustainability, the humble conveyor belt has taken on a mission-critical role. In this exclusive interview, Kamlesh Jain, Managing Director, Elastocon, discusses how the company is innovating for tougher terrains, smarter systems and a greener tomorrow.

Brief us about your company – in terms of its offerings, manufacturing facilities, and the key end-user industries it serves.

Elastocon, a flagship brand of the Royal Group, is a trusted name in the conveyor belt manufacturing industry. Under the brand name ELASTOCON, the company produces both open-end and endless belts, offering tailor-made solutions to some of the most demanding sectors such as cement, steel, power, mining, fertiliser, and logistics. Every belt is meticulously engineered—from fabric selection to material composition—to ensure optimal performance in tough working conditions. With advanced manufacturing facilities and strict quality protocols, Elastocon continues to deliver high-performance conveyor solutions designed for durability, safety, and efficiency.

How is the group addressing the needs for efficient material handling?

Efficient material handling is the backbone of any industrial operation. At Elastocon, our engineering philosophy revolves around creating belts that deliver consistent performance, long operational life, and minimal maintenance. We focus on key performance parameters such as tensile strength, abrasion resistance, tear strength, and low elongation at working tension. Our belts are designed to offer superior bonding between plies and covers, which directly impacts their life and reliability. We also support clients

with maintenance manuals and technical advice, helping them improve their system’s productivity and reduce downtime.

How critical are conveyor belts in ensuring seamless material handling?

Conveyor belts are a vital link in the supply chain across industries. In sectors like mining, cement, steel, and logistics, they facilitate the efficient movement of materials and help maintain uninterrupted production flows. At Elastocon, we recognise the crucial role of belts in minimising breakdowns and increasing plant uptime. Our belts are built to endure abrasive, high-temperature, or high-load environments. We also advocate proper system maintenance, including correct belt storage, jointing, roller alignment, and idler checks, to ensure smooth and centered belt movement, reducing operational interruptions.

What are the key market and demand drivers for the conveyor belt industry?

The growth of the conveyor belt industry is closely tied to infrastructure development, increased automation, and the push for higher operational efficiency. As industries strive to reduce labor dependency and improve productivity, there is a growing demand for advanced material handling systems. Customers today seek not just reliability, but also cost-effectiveness and technical superiority in the belts they choose. Enhanced product aesthetics and innovation in design are also becoming significant differentiators. These trends are pushing manufacturers to evolve continuously, and Elastocon is leading the way with customer-centric product development.

How does Elastocon address the diverse and evolving requirements of these sectors?

Our strength lies in offering a broad and technically advanced product portfolio that serves various industries. For general-purpose applications, our M24 and DINX/W grade belts offer excellent abrasion resistance, especially for RMHS and cement plants. For high-temperature operations, we provide HR and SHR T2 grade belts, as well as our flagship PYROCON and PYROKING belts, which can withstand extreme heat—up to 250°C continuous and even 400°C peak—thanks to advanced EPM polymers.

We also cater to sectors with specialised needs. For fire-prone environments like underground mining, we offer fire-resistant belts certified to IS 1891 Part V, ISO 340, and MSHA standards. Our OR-grade belts are designed for oil and chemical resistance, making them ideal for fertiliser and chemical industries. In high-moisture applications like food and agriculture, our MR-grade belts ensure optimal performance. This diverse range enables us to meet customer-specific challenges with precision and efficiency.

What core advantages does Elastocon offer that differentiate it from competitors?

Elastocon stands out due to its deep commitment to quality, innovation, and customer satisfaction. Every belt is customised to the client’s requirements, supported by a strong R&D foundation that keeps us aligned with global standards and trends. Our customer support doesn’t end at product delivery—we provide ongoing technical assistance and after-sales service that help clients maximise the value of their investments. Moreover, our focus on compliance and certifications ensures our belts meet stringent national and international safety and performance standards, giving customers added confidence.

How is Elastocon gearing up to meet its customers’ evolving needs?

We are conscious of the shift towards greener and smarter manufacturing practices. Elastocon is embracing sustainability by incorporating eco-friendly materials and energy-efficient manufacturing techniques. In parallel, we are developing belts that seamlessly integrate with automated systems and smart industrial platforms. Our vision is to make our products not just high-performing but also future-ready—aligned with global sustainability goals and compatible with emerging technologies in industrial automation and predictive maintenance.

What trends do you foresee shaping the future of the conveyor belt industry?

The conveyor belt industry is undergoing a significant transformation. As Industry 4.0 principles gain traction, we expect to see widespread adoption of smart belts equipped with sensors for real-time monitoring, diagnostics, and predictive maintenance. The demand for recyclable materials and sustainable designs will continue to grow. Furthermore, industry-specific customisation will increasingly replace standardisation, and belts will be expected to do more than just transport material—they will be integrated into intelligent production systems. Elastocon is already investing in these future-focused areas to stay ahead of the curve.

Advertising or branding is never about driving sales. It’s about creating brand awareness and recall. It’s about conveying the core values of your brand to your consumers. In this context, why is branding important for cement companies? As far as the customers are concerned cement is simply cement. It is precisely for this reason that branding, marketing and advertising of cement becomes crucial. Since the customer is unable to differentiate between the shades of grey, the onus of creating this awareness is carried by the brands. That explains the heavy marketing budgets, celebrity-centric commercials, emotion-invoking taglines and campaigns enunciating the many benefits of their offerings.

Marketing strategies of cement companies have undergone gradual transformation owing to the change in consumer behaviour. While TV commercials are high on humour and emotions to establish a fast connect with the customer, social media campaigns are focussed more on capturing the consumer’s attention in an over-crowded virtual world. Branding for cement companies has become a holistic growth strategy with quantifiable results. This has made brands opt for a mix package of traditional and new-age tools, such as social media. However, the hero of every marketing communication is the message, which encapsulates the unique selling points of the product. That after all is crux of the matter here.

While cement companies are effectively using marketing tools to reach out to the consumers, they need to strengthen the four Cs of the branding process – Consumer, Cost, Communication and Convenience. Putting up the right message, at the right time and at the right place for the right kind of customer demographic is of utmost importance in the long run. It is precisely for this reason that regional players are likely to have an upper hand as they rely on local language and cultural references to drive home the point. But modern marketing and branding domain is exponentially growing and it would be an interesting exercise to tabulate and analyse its impact on branding for cement.

Refractory demands in our kiln have changed

Digital supply chain visibility is critical

Redefining Efficiency with Digitalisation

Cement Additives for Improved Grinding Efficiency

Digital Pathways for Sustainable Manufacturing

Refractory demands in our kiln have changed

Digital supply chain visibility is critical

Redefining Efficiency with Digitalisation

Cement Additives for Improved Grinding Efficiency