Concrete

LC3 cement

Published

5 years agoon

By

admin

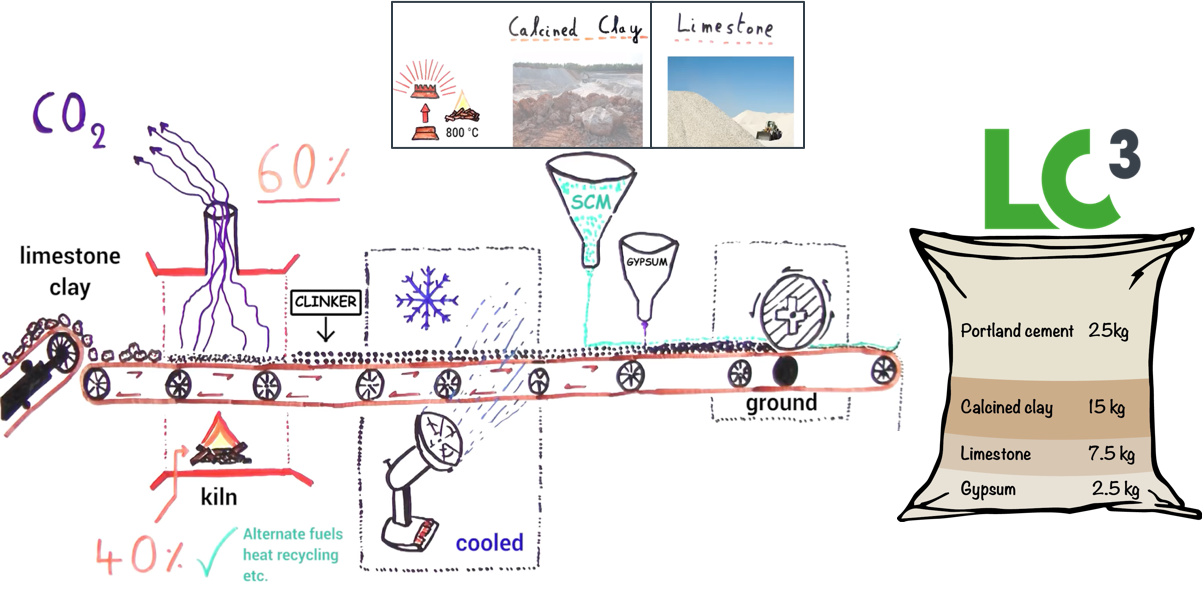

LC3 is a new type of cement that is based on a blend of limestone and calcined clay. LC3 can reduce CO2 emissions by up to 40 percent, is made using limestone and low-grade clays which are available in abundant quantities,is cost effective and does not require capital intensive modifications to existing cement plants.

The objective of the LC3-Project is, through research and testing, to make LC3 standard and mainstream general-use cement in the global cement market.

The main research activities focus not only on specific thematic areas of cement research but also on production, environmental sustainability and cost effectiveness of this new cement.

With funding from the Swiss Agency for Development and Cooperation through its Global Programme in Climate Change, that has been able to bring the idea of the LC3-technology from the lab in Switzerland to all parts of the world.

Difference between LC3 and conventional Portland cement

Traditional Portland cement consists of 95% clinker. The production of it is energy-intensive and responsible for most of the CO2 within the cement. By reducing the clinker-content with so called Supplementary Cementitious Materials (SCMs), large CO2-savings can be achieved.

LC3 is a new blend of two materials which have a synergetic effect. can reduce half of the clinker content and thereby cut up to 40% of the CO2-emissions. Furthermore, LC3 uses industrial waste materials which thereby increase the resource efficiency and reduce the utilization of the scarce raw materials that are necessary for producing clinker.

How to produce LC3?

To produce LC3, existing equipment can be used. The production line has to be adjusted since Limestone and Calcined Clay are added. The LC3-blend consists of the following materials:

Clinker that needs to be burnt at very high temperatures between 1400 and 1500?C.

-

Calcined clays are burnt at approximately 800?C.

-

Limestone is added without processing

-

Gypsum for workability

LC3-has been used in many different regions and different scales. Overall, more than 25 applications were already built with LC3. In Latin America, several applications have been built. They are mainly in Cuba but also in other countries. Among those applications are a LC3-house, testing sites in the sea, art sculptures and pavements.

In India, the most prominent project is the model Jhansi, India. This house is made 98% out of LC3 and it used 26.6 t of industrial waste (192 kg/sqm) and Saved 15.5 t of CO2 (114 kg/sqm). These CO2-savings are similar to the emissions of 10 passengers traveling by plane from Switzerland to South Africa.

Model house in Jhansi

But there are also numerous other projects in India. For example, the offices of the Swiss Agency for Development and Cooperation in the compound of the Swiss Embassy in Delhi were built with LC3-prefab materials. Furthermore, some roads, a check damn and pavements were built.You find a selection of these applications on the photos.

Swiss Embassy building in Delhi Check dam in Orchha CO2-savings LC3 saves up to 40% of CO2 as compared to Ordinary Portland Cement. Most of the CO2 comes from the clinkerisation process. Therefore, reducing the clinker factor and replacing it with SCMs is the fastest intervention to save high numbers of CO2.

Within the clinker production, there are two main sources of CO2. Firstly, clinker needs to be burnt at very high temperatures between 1400 and 1500?C. Secondly, CO2 embodied in limestone is released during production. Reducing the clinker content therefore means to save both energy-related and emobied CO2.

Resource-savings

Utilization of lower grade material for LC3. Clay waste e.g. ceramic or cosmetic industry Less purity of limestone required, e.g. dolomite presence Using existing deposits of waste materials Low prices for the raw materials. Avoiding creating waste. Avoiding cost (e.g. for landfill taxes)

High performance

For more than 10 years, the prestigious research institutes EPFL, IIT Delhi and Madras and CIDEM have tested LC3 in all different aspects and came to the result LC3 reaches OPC – CEM I performance.

Not only in lab conditions but also through industrial trials and applications these findings were confirmed. They are constantly monitored in existing LC3-applications in different parts of the world and environments (e.g. marine or high-altitude applications).

Globally scalable

The raw materials limestone and calcined clay are abundantly available worldwide. Other commonly used Supplementary Cementitious Materials like fly ash or slag are already fully used and cannot be scaled for the use in cement. Furthermore, with increasing focus on sustainability more and more coal power and steel production plants are expected to be closed. This will further cut the supply of these materials as SCMs. The only material largely available and in sufficient quantity are kaolinitic clays.

Cost-effective

Different scenarios of producing LC3 were analysed financially in a study by the cement market experts. Their results showed that with a cement plant, grinding plant or Greenfield scenario the production of LC3 is profitable. The main indicator for driving the profitability is the close access to suitable clays.

Overall, the production cost can be up to 25% lower for LC3 than for OPC due to savings for energy and material. This is without additional policy incentives, such as green funds or carbon certificates, which can further increase the attractiveness for cement producers.

Ready to be implemented

LC3 is a technology which is market-ready and it is already produced in several plants in the world. The sooner the technology is rolled out globally; the more CO2-emissions can be avoided.

The already existing readiness of the technology for the industrial uptake is an important distinction compared to other green technologies.

Furthermore, LC3 can be used without additional training by builders. In India, demo constructions were built without further providing training.

Source: LC3 website.

You may like

-

Branding Concrete with Virtual and Augmented Reality

-

LafargeHolcim launches industrial automation plan

-

Ambuja Cement scouts for buys in RMX to fuel growth

-

Construction sector shows degrowth for the past 3 years

-

China´s ministry investigates excessive cement capacity in north-east China

-

Vincent Leboucher is new president of HGH Group

Concrete

Merlin Prime Spaces Acquires 13,185 Sq M Land Parcel In Pune

Rs 273 crore purchase broadens the developer’s Pune presence

Published

4 hours agoon

March 6, 2026By

admin

Merlin Prime Spaces (MPS) has acquired a 13,185 sq m land parcel in Pune for Rs 273 crore, marking a notable expansion of its footprint in the city.

The transaction value converts to Rs 2,730 mn or Rs 2.73 bn.

The parcel is located in a strategic area of Pune and the firm described the acquisition as aligned with its growth objectives.

The deal follows recent activity in the region and will be watched by investors and developers.

MPS said the acquisition will support its planned development pipeline and enable delivery of commercial and residential space to meet local demand.

The company expects the site to provide flexibility in product design and phased development to respond to market conditions.

The move reflects an emphasis on land ownership in key suburban markets.

The emphasis on land acquisition reflects a strategy to secure inventory ahead of demand cycles.

The purchase follows a period of sustained investor interest in Pune real estate, driven by expanding office ecosystems and residential demand from professionals.

MPS will integrate the new holding into its existing portfolio and plans to engage with local authorities and stakeholders to progress approvals and infrastructure readiness.

No financial partners were disclosed in the announcement.

The firm indicated that timelines will depend on approvals and prevailing market conditions.

Analysts note that strategic land acquisitions at scale can help developers manage costs and timelines while preserving optionality for future projects.

MPS will now hold an enlarged land bank in the region as it pursues growth, and the acquisition underlines continued corporate appetite for measured expansion in second tier cities.

The company intends to move forward with detailed planning in the coming months.

Stakeholders will assess how the site is positioned relative to existing infrastructure and connectivity.

Concrete

Adani Cement and Naredco Partner to Promote Sustainable Construction

Collaboration to focus on skills, technology and greener practices

Published

4 hours agoon

March 6, 2026By

admin

Adani Cement has entered a strategic partnership with the National Real Estate Development Council (Naredco) to support India’s construction needs with a focus on sustainability, workforce capability and modern building technologies. The collaboration brings together Adani Cement’s building materials portfolio, research and development strengths and technical expertise with Naredco’s nationwide network of more than 15,000 member organisations. The agreement aims to address evolving demand across housing, commercial and infrastructure sectors.

Under the partnership, the organisations will roll out skill development and certification programmes for masons, contractors and site supervisors, with training to emphasise contemporary construction techniques, safety practices and quality standards. The programmes are intended to improve project execution and on-site efficiency and to raise labour productivity through standardised competencies. Emphasis will be placed on practical training and certification pathways that can be scaled across regions.

The alliance will function as a platform for knowledge sharing and technology exchange, facilitating access to advanced concrete solutions, innovative construction practices and modern materials. The effort is intended to enhance structural durability, execution quality and environmental responsibility across developments while promoting adoption of low-carbon technologies and green cement alternatives. Companies expect these measures to contribute to longer term resilience of built assets.

Senior executives conveyed that the partnership reflects a shared commitment to strengthening quality and sustainability in construction and that closer engagement with developers will help integrate advanced materials and technical support throughout the project lifecycle. Leadership noted the need for responsible construction practices as urbanisation accelerates and indicated that the association should encourage wider adoption of green building norms and collaboration within the real estate and construction ecosystem.

The organisations said they will also explore integrated building solutions, including ready-mix concrete offerings, while supporting initiatives aligned with affordable and inclusive housing. The partnership will progress through engagements, conferences and joint training programmes targeting rapidly urbanising cities and growth centres where demand for efficient and environmentally responsible construction grows. Naredco, established under the aegis of the Ministry of Housing and Urban Affairs, will leverage its policy and advocacy role to support implementation.

Operational excellence in cement is no longer about producing more—it is about producing smarter, cleaner and more reliably, where cost per tonne meets carbon per tonne.

Operational excellence in cement has moved far beyond the old pursuit of ‘more tonne’. The new benchmark is smarter, cleaner, more reliable production—delivered with discipline across process, people and data. In an industry where energy can account for nearly 30 per cent of manufacturing cost, even marginal gains translate into meaningful value. As Dr SB Hegde, Professor, Jain College of Engineering & Technology, Hubli and Visiting Professor, Pennsylvania State University, USA, puts it, “Operational excellence… is no longer about producing more. It is about producing smarter, cleaner, more reliably, and more sustainably.” The shift is structural: carbon per tonne will increasingly matter as much as cost per tonne, and competitiveness will be defined by the ability to stabilise operations while steadily lowering emissions.

From control rooms to command centres

The modern cement plant is no longer a handful of loops watched by a few operators. Control rooms have evolved from a few hundred signals to thousands—today, up to 25,000 signals can compete for attention. Dr Rizwan Sabjan, Head – Global Sales and Proposals, Process Control and Optimization, Fuller Technologies, frames the core problem plainly: plants have added WHRS circuits, alternative fuels, higher line capacities and tighter quality expectations, but human attention remains finite. “It is very impossible for an operator to operate the plant with so many things being added,” he says. “We need somebody who can operate 24×7… without any tiredness, without any distraction… The software can do that for us better.”

This is where advanced process control shifts from ‘automation spend’ to a financial lever. Dr Hegde underlines the logic: “Automation is not a technology expense. It is a financial strategy.” In large kilns, a one per cent improvement is not incremental—it is compounding.

Stability is the new productivity

At the heart of operational excellence lies stability. Not because stability is comfortable, but because it is profitable—and increasingly, low-carbon. When setpoints drift and operators chase variability, costs hide in refractory damage, thermal shocks, stop-start losses and quality swings. Dr Sabjan argues that algorithmic control can absorb process disturbances faster than any operator, acting as ‘a co-pilot or an autopilot’, making changes ‘as quick as possible’ rather than waiting for manual intervention. The result is not just fuel saving—it is steadier operation that extends refractory life and reduces avoidable downtime.

The pay-off can be seen through the lens of variability: manual operation often amplifies swings, while closed-loop optimisation tightens control. As Dr Sabjan notes, “It’s not only about savings… there are many indirect benefits, like increasing the refractory life, because we are avoiding the thermal shocks.”

Quality control

If stability is the base, quality is the multiplier. A high-capacity plant can dispatch enormous volumes daily, and quality cannot be a periodic check—it must be continuous. Yet, as Dr Sabjan points out, the biggest error is not in analysis equipment but upstream: “80 per cent of the error is happening at the sampling level.” If sampling is inconsistent, even the best XRF and XRD become expensive spectators.

Automation closes the loop by standardising sample collection, transport, preparation, analysis and corrective action. “We do invest a lot of money on analytical equipment like XRD and XRF, but if it is not put on the closed loop then there’s no use of it,” he says, because results become person-dependent and slow.

Raju Ramachandran, Chief Manufacturing Officer (East), Nuvoco Vistas Corp, reinforces the operational impact from the plant floor: “There’s a stark difference in what a RoboLab does… ensuring that the consistent quality is there… starts right from the sample collection.” For him, automation is not about removing people; it is about making outcomes repeatable.

Human-centric automation

One of the biggest barriers to performance is not hardware—it is fear. Dr Sabjan describes a persistent concern that digital tools exist to replace operators. “That’s not the way,” he says. “The technology is here to help operator… not to replace them… but to complement them.” The plants that realise this early tend to sustain performance because adoption becomes collaborative rather than forced.

Dr Hegde adds an important caveat: tools can mislead without competence. “If you don’t have the knowledge about the data… this will mislead you… it is like… using ChatGPT… it may tell the garbage.” His point is not anti-technology; it is pro-capability. Operational excellence now requires multidisciplinary teams—process, chemistry, physics, automation and reliability—working as one.

GS Daga, Managing Director, SecMec Consultants, takes the argument further, warning that the technology curve can outpace human readiness: “Our technology movement AI will move fast, and our people will be lagging behind.” For him, the industry’s most urgent intervention is systematic skilling—paired with the environment to apply those skills. Without that, even high-end systems remain underutilised.

Digital energy management

Digital optimisation is no longer confined to pilots; its impact is increasingly quantifiable. Raghu Vokuda, Chief Digital Officer, JSW Cement, describes the outcomes in practical terms: reductions in specific power consumption ‘close to 3 per cent to 7 per cent’, improvements in process stability ‘10 per cent to 20 per cent’, and thermal energy reductions ‘2–5 per cent’. He also highlights value beyond the process line—demand optimisation through forecasting models can reduce peak charges, and optimisation of WHRS can deliver ‘1 per cent to 3 per cent’ efficiency gains.

What matters is the operating approach. Rather than patchwork point solutions, he advocates blueprinting a model digital plant across pillars—maintenance, quality, energy, process, people, safety and sustainability—and then scaling. The difference is governance: defined ownership of data, harmonised OT–IT integration, and dashboards designed for each decision layer—from shopfloor to plant head to network leadership.

Predictive maintenance

Reliability has become a boardroom priority because the cost of failure is blunt and immediate. Dr Hegde captures it crisply: “One day of kiln stoppage can cost several crores.” Predictive maintenance and condition monitoring change reliability from reaction to anticipation—provided plants invest in the right sensors and a holistic architecture.

Dr Sabjan stresses the need for ‘extra investment’ where existing instrumentation is insufficient—kiln shell monitoring, refractory monitoring and other critical measurements. The goal is early warning: “How to have those pre-warnings… where the failures are going to come… and then ensure that the plant availability is high, the downtime is low.”

Ramachandran adds that IoT sensors are increasingly enabling early intervention—temperature rise in bearings, vibration patterns, motor and gearbox signals—moving from prediction to prescription. The operational advantage is not only fewer failures, but planned shutdowns: “Once the shutdown is planned in advance… you have lesser… unpredictable downtimes… and overall… you gain on the productivity.”

Alternative fuels and raw materials

As decarbonisation tightens, AFR becomes central—but scaling it is not simply a procurement decision. Vimal Kumar Jain, Technical Director, Heidelberg Cement, frames AFR as a structured programme built on three foundations: strong pre-processing infrastructure, consistent AFR quality, and a stable pyro process. “Only with the fundamentals in place can AFR be scaled safely—without compromising clinker quality or production stability.”

He also flags a ground reality: India’s AFR streams are often seasonal and variable. “In one season to another season, there is major change… high variation in the quality,” he says, making preprocessing capacity and quality discipline mandatory.

Ramachandran argues the sector also needs ecosystem support: a framework for AFR preprocessing ‘hand-in-hand’ between government and private players, so fuels arrive in forms that can be used efficiently and consistently.

Design and execution discipline

Operational excellence is increasingly determined upstream—by the choices made in concept, layout, technology selection, operability and maintainability. Jain puts it unambiguously: “Long term performance is largely decided before the plant is commissioned.” A disciplined design avoids bottlenecks that are expensive to fix later; disciplined execution ensures safe, smooth start-up with fewer issues.

He highlights an often-missed factor: continuity between project and operations teams. “When knowledge transfer is strong and ownership carries beyond commissioning, the plant stabilises much faster… and lifecycle costs reduce significantly.”

What will define the next decade

Across the value chain, the future benchmark is clear: carbon intensity. “Carbon per ton will matter as much as cost per ton,” says Dr Hegde. Vokuda echoes it: the industry will shift from optimising cost per tonne to carbon per ton.

The pathway, however, is practical rather than idealistic—low-clinker and blended cements, higher thermal substitution, renewable power integration, WHRS scaling and tighter energy efficiency. Jain argues for policy realism: if blended cement can meet quality, why it shall not be allowed more widely, particularly in government projects, and why supplementary materials cannot be used more ambitiously where performance is proven.

At the same time, the sector must prepare for CCUS without waiting for it. Jain calls for CCUS readiness—designing plants so capture can be added later without disruptive retrofits—while acknowledging that large-scale rollout may take time as costs remain high.

Ultimately, operational excellence will belong to plants that integrate—not isolate—the levers: process stability, quality automation, structured AFR, predictive reliability, disciplined execution, secure digitalisation and continuous learning. As Dr Sabjan notes, success will not come from one department owning the change: “Everybody has to own it… then only… the results could be wonderful.”

And as Daga reminds the industry, the future will reward those who keep their feet on the ground while adopting the new: “I don’t buy technology for the sake of technology. It has to make a commercial sense.” In the next decade, that commercial sense will be written in two numbers—cost per tonne and carbon per tonne—delivered through stable, skilled and digitally disciplined operations.

Merlin Prime Spaces Acquires 13,185 Sq M Land Parcel In Pune

Adani Cement and Naredco Partner to Promote Sustainable Construction

Operational Excellence Redefined!

World Cement Association Annual Conference 2026 in Bangkok

Assam Chief Minister Opens Star Cement Plant In Cachar

Merlin Prime Spaces Acquires 13,185 Sq M Land Parcel In Pune

Adani Cement and Naredco Partner to Promote Sustainable Construction

Operational Excellence Redefined!

World Cement Association Annual Conference 2026 in Bangkok

Assam Chief Minister Opens Star Cement Plant In Cachar

Trending News

-

Economy & Market4 weeks ago

Economy & Market4 weeks agoFORNNAX Appoints Dieter Jerschl as Sales Partner for Central Europe

-

Concrete2 weeks ago

Concrete2 weeks agoRefractory demands in our kiln have changed

-

Concrete2 weeks ago

Concrete2 weeks agoDigital supply chain visibility is critical

-

Concrete2 weeks ago

Concrete2 weeks agoOur strategy is to establish reliable local partnerships