Technology

FLSmidth Laboratory Automation Solution

Published

9 years agoon

By

admin

FLSmidth, an important cement industry equipment and service provider, has its own version of a robotic laboratory. The facility helps to control cement quality and fully meets industry standards for reliability and robustness in an industrial environment.

Cement plants are facing increasingly tough requirements for sample analysis quality and complexity, and for sample throughput. This is partly a result of environmental regulations placing stricter controls on cement production, both in terms of pollution and energy consumption.

In addition, the current economic climate demands 24/7/365 cement plant operation, with as little manpower as possible, with increased productivity.

Many cement plants are in areas where it is difficult to recruit skilled engineers, and people who are available often spend less time in the same job. Remote operation, support from distant locations, and online assistance are all vital for the smooth operation of quality control systems in modern cement plants. The trend in cement plant quality control systems is to meet the following requirements:

Improve the speed and accuracy of sample results;

Meet the stricter controls required for the cement market;

Support 24/7/365 operations;

Achieve zero health and safety incidents.

Supporting product quality control at all stages

The QCX? system from FLSmidth is designed to control cement quality in cement plants and it fully meets industry standards for reliability and robustness in an industrial environment. Automated sampling, sample preparation and analysis provide fast, reliable and consistent information for quality and process control.

The system supports quality control at all relevant stages of cement production in a single, integrated system. Combined with FLSmidth’s extensive experience in cement plant process control, the system incorporates in-depth understanding of production environments and the high requirements for speed and performance. The modular system architecture allows for any degree of automation.

It can be scaled from small task-targeted automation units to large, fully automated laboratories.

KPI for the Quality Laboratory

- Cost-effective production with high quality;

- Strict documentation requirements;

- Continuous plant operation.

Cost-effective production with high quality

Cement production requires fast and correct results to improve quality and reduce operational costs. The Laboratory Automation System transports the samples from the plant to the laboratory; the samples travel 1,500 metres in seconds. The Centaurus, Combined Mill and Press prepare the sample for XRF analysis. The entire process of sampling, preparation and analysis of various equipment like XRF, Free Lime Analysis and Blaine analysis can be done together in the automated laboratory in a foolproof system.

Strict documentation requirements

Stricter QC and audit trail requirements are part of the daily operation of cement plants. The QCX system supports unmanned documented handling of material from process to analysis, avoiding introducing human errors.

Continuous plant operation

For 24/7 plant operation, the process laboratory must operate constantly with only very few, short stops. This means that efficient maintenance and service of all equipment is crucial. To support 24/7 plant operation, the QCX system monitors key components’ KPIs, enabling verification of run hours and end of lifetime for wear parts facilitating spare-part sourcing and reducing downtime for maintenance is part of FLSmidth ‘s global support organisation for fast and easy remote troubleshooting.

A solution for every need

FLSmidth’s comprehensive equipment portfolio, designed specifically for cement production laboratories, ranges from manual machines and automated units to fully automated, high-capacity laboratories. By design, most of FLSmidth’s laboratory equipment is semi-automated and can also be operated manually, as standalone equipment. This means you have the advantage of implementing stepwise automation and of ensuring operation, even when part of the automated laboratory is being serviced.

The QCX system ensures that your process laboratory delivers safe, efficient and accurate analysis quickly and with as few operators as possible. The advanced, user-friendly system can be tailored according to your specific cement production needs, including special cement and fuels, and supports 24/7/365 operation. More than 40 years of development across multiple hardware platforms and a comprehensive base of installed systems has made the QCX system the frontrunner in the cement industry. Automated laboratory solutions from FLSmidth are setting new industrial standards in terms of ease of use, flexibility, reliability and scalability.

Inconsistency in sampling

Sampling inconsistency and inaccurate analysis results contribute to laboratory errors, creating process fluctuations and disrupting productivity, equipment lifetime and especially product quality.

Sampling is the critical first step in the quality control chain. Without correct sampling, preparation and analysis are only a lottery. Balancing your cement plant’s chemistry can be challenging. Sampling inconsistency and inaccurate analysis results contribute to laboratory errors. These errors create process fluctuations and disrupt productivity, reducing equipment life while jeopardizing product quality. According to ‘Sample Theory Studies’, the quality errors come from: Sampling (86.5 per cent); preparation (9 per cent) and analysis (4.5 per cent).

Accurate, automatic sample analysis assists you to take control of your cement plant’s chemistry, its performance and the quality of its output.

QCX/AutoSampling V8 from FLSmidth controls automatic sampling and pneumatic transport of sampled material from the process areas to the production laboratory, and it remains unmatched in its software functionality and performance.

Automated sampling results in samples being taken at the right time, at the right place and consistently. It’s a safe choice. It also:

- Ensures sampling quality remains high and samples are representative of the larger production;

- Allows for fail-safe sample identification, including timestamp;

- Minimises sample-to-sample cross contamination;

- Provides automated composite/average sampling.

Automated sampling combined with automatic transportation results in:

- Fast turnaround times from sampling to analysis;

- Full sample traceability – where and when was this sample taken;

- Improved quality control;

- Optimised overall sample-taking schedule;

- Flexible operator call for additional samples;

- High system availability;

- Easy connectivity to automatic sample preparation systems;

- No health and safety issues as no humans are needed for sample taking;

- Less labour requirements, allowing the workforce to undertake other important tasks;

- Improved and fast troubleshooting and maintenance through informative faceplates describing all information from the samplers and sending stations;

- Tube transport systems have been employed for fast sample transportation in harsh industrial environments since the 1960s. FLSmidth has been involved since the early days and has gained a market-leading position within this technology through execution of hundreds of projects with automated sampling and sample transportation to customers worldwide;

- QCX/AutoSampling provides automatic sampling and pneumatic transport of sampled material from the process areas to a central production laboratory or to designated ‘satellite’ laboratories;

- Manual, semi-automatic, or fully automated send/receive stations are available both at the process end and at the laboratory end of a pneumatic sample transport system. Sampling equipment for powder, granulate or and lumpy materials can be connected to the process send/receive stations, thereby ensuring fully automated procedures;

- Samples are transported in sample cartridges (or carriers or shuttles). For dry powder/granulates, typically 200-500 cc material is sent to the laboratory;

- The applied advanced logic control programming techniques (oQCXSYSo) ensures cost-effective engineering for the specific project as well as providing a very high quality and consistency in both overall and device control. Directly from the PC screen, mimic diagrams (so-called ‘face-plates’) provide easy accessible operational and diagnostic details from the device control level.

- Samples are sent from the process stations to receive/send stations in the laboratory in accordance with individual sample priorities and wait list status. Sample entities like sampling location, product type, sampling time, etc., are automatically passed on to the next handling stage, whether manual or automatic. The integrated automation concept includes advanced priority handling schemes: in case an equipment error leads to reduced capacity in the automated preparation system, it is possible to automatically scale down the automatic sampling & sample transport activity, so that lower priority samples are skipped or called for less frequently;

- Automatic sample transport complements automatic sampling and creates fully automated sampling procedures;

- Fast turnaround time from sampling to analysisl;

- Improved product quality and related operational savings;

- Optimised overall sample taking schedule;

- High system availability;

- Easy connectivity to automatic sample preparation systems;

- Worldwide service & support.

Sampling made easy

QCX/AutoSampling V8 can be seamlessly configured to suit your work processes. FLSmidth has semi- and fully-automated samplers for all cement plant applications – from raw material to cement dispatch including a new hot kiln outlet sampler that enables very fast clinker analysis, and thereby fast feedback to chemical changes introduced in the kiln. With its intuitive user interfaces, and informative faceplates, the system provides a complete overview of all sampling issues directly at the laboratory. Most importantly, it delivers reliable samples!

FLSmidth has more than 200 QCX/AutoSampling systems installed worldwide. Fast and accurate sample preparation and analysis results in greater quality control. It sets your production capabilities apart from the rest.

FLSmidth QCX Robolab

FLSmidth’s QCX/RoboLab aims to simplify some of those complexities. The single, integrated QCX/RoboLab system uses leading-edge technology to deliver automated sampling, sample pre?paration and analysis that’s fast and reliable, and provides consistent information for quality and process control at all stages of cement production.

QCX/RoboLab V8 – improved quality, reduced variance

QCX/RoboLab reduces the hard, repetitive and sometimes hazardous work in the laboratory, to reduce human errors, and to ensure safe, fast, reliable and accurate analysis. It is instrumental in achieving optimum performance.

A QCX/RoboLab system consists of semi-automated sample preparation equipment, sample manipulators, such as a robot or conveyers and manipulators, and state-of-the-art software to handle both the automation and the sample control and laboratory information management system (LIMS) functionalities.

QCX/RoboLab allows for varying degrees of automation. It can be scaled from small, task-targeted automation units to large, fully automated laboratories. Installations have ranged from systems with one robot, one sample preparation machine and one analyser to systems with eight robots and numerous other equipment.

All-in-one combined mill & press

The only all-in-one automated solution that can grind and press or just grind or just press.

FLSmidth’s ‘Centaurus’ automatic sample preparation machine combines laboratory mill and press functions in a compact, easy-to-operate unit. Centaurus consists of an automatic fine grinding mill and an automatic pelletising press. The components for both these main functionalities are integrated in a space-saving and ergonomically designed (award-winning) housing with a footprint of only 1 m2.

The fully automatic Centaurus produces pressed powder test tablets from granular materials such as raw meal, clinker, cement, ore, slag and mine exploration samples for XRF and XRD analysis. Automated quality control systems help improve the product quality in industrial processes. FLSmidth has taken product quality one step further with the unique Centaurus sample preparation machine.

Functionality

The Centaurus houses a sample dosing device, an automatic fine-grinding mill and an automatic pelletising press in a soundproof 1m2 unit. It fits seamlessly into new or existing production laboratory set-ups.

Designed to function as a standalone system or to be integrated with linear or robotics automation systems, the Centaurus has two different operation sides – a human and an automatic side, which allows a smoothly integration into FLSmidth’s QCX/RoboLab system, as well as the use as a standalone machine, because the Centaurus supports automatic feed of samples directly to any X-ray analyser.

The unique thing about Centaurus is its ability to grind sample material without pressing it, or to press sample material without grinding it.

The ‘grinding only’ feature is a standard functionality, while the ‘pressing only’ feature is an available option. Before the grinding and pressing stage, the sample material type is identified from the operator terminal, or via the interface of a supervisory quality control system such as the QCX system.

The preparation method and associated parameters are then selected and the fully automatic sample preparation process begins:

In the flagship of fully-automated sample processing, QCX/RoboLab, the Centaurus plays the main role in sample preparation.

Arriving in the automatic receiving station and filled in the cups, the robot transfers the sample to the Centaurus where the fully automatic sample preparation cycle starts.

From the output position the pressed tablet is placed on the belt leading to the X-ray machine.

QCX/Blend Expert V8

FLSmidth has more than 700 QCX/Blend Expert applications installed worldwide. With QCX/Blend Expert, the complex task of controlling varying raw materials is no longer manual. Its tight control of raw material blending reduces fuel consumption in the kiln, and it delivers kiln feed quality out of the mill, eliminating the need for well working blending silos.

Easy to install, easier to use

FLSmidth has combined more than 40 years of experience in material proportioning in the development of QCX/BlendExpert V8. The software offers significant improvements for all cement plants.

It has been designed using the latest control technologies and can be installed on a standard PC, physical or virtual, standalone or on top of another QCX system. It has an easy-to-interpret graphical interface and advanced alarm and trend capabilities.

For further details, contact: S. Sankaralingam

(Ph. +91 7358058894); Altrin Prabahar. S.

(Ph.+91 7358046923), FLSmidth Ltd.

Maximum efficiency, higher productivity

QCX/BlendExpert provides cement plants with a competitive edge and allows plant owners and managers to achieve what other plants without advanced quality control systems can’t achieve.

- Up to 60% lower standard deviation of quality targets.

- Fast payback of system investment

- due to:

- Lower fuel consumption in the kiln and pre-heater;

- Reduced equipment wear and longer lifetime of mechanical parts – less thermal stress is a direct benefit of QCX/BlendExpert’s stable burning.

- Reduced need for blending silos.

- Higher kiln alternative fuel substitution rate.

- Steady 24/7/365 control philosophy.

- Intuitive user interface, providing easy overview of ‘next step’ process control.

- Fast troubleshooting of material feeders through direct monitoring of feeder operation.

- Improved accuracy and benefits of online analysers through dynamic bias correction and automated handling.

- Optimal use of raw materials and additives, leading to cost savings.

- Optimal control of material blending during upset conditions – no need to switch to manual control.

You may like

Ponnusamy Sampathkumar, Consultant – Process Optimisation and Training, discusses the role of skilled operators as the decisive link between advanced additives, digital control and world-class mill performance.

The industry always tries to reduce the number of operators in the Centre Control Room. (CCR) Though the concept was succeeded to certain extent, still we need a skilled person in the CCR.

In an era where artificial intelligence (AI) grinding aids, performance enhancers, and digital optimisation tools are becoming increasingly sophisticated, it’s tempting to believe that chemistry alone can solve the challenges of mill efficiency. Yet plants that consistently outperform their peers share one common trait: highly skilled operators who understand the mill as a living system, not just a machine.

Additives can improve flowability, reduce agglomeration, and enhance separator efficiency, but they cannot replace the nuanced judgement that comes from experience. Grinding is a dynamic process influenced by raw material variability, moisture, liner wear, ball charge distribution, ventilation, and separator loading. No additive can fully compensate for poor control of these fundamentals.

Operators see what additives cannot

When I joined the cement industry in 1981, not much modernisation was available then. Mostly the equipment was run from the local panel. Once I was visiting the cement mills section. The cement mills were water sprayed over the shell to reduce the temperature to avoid the gypsum disintegration.

The operator stopped the feeding for one of the mills. When I asked the reason, he replied that mill was getting jammed, and he added that he could understand the mill condition by its sound. I also learned that and it was useful throughout my career. In another plant I saw the ‘Electronic Ear,’ which checked the sound of the mill and the signal was looped with feed control!

Whatever modernisation we achieve, it is from the human factor that the development starts.

Additives respond to conditions; operators interpret them.

A skilled operator can detect subtle shifts, like a change in mill sound, a slight variation in circulating load, or a drift in separator cut point. It’s long before instrumentation flags a problem. These micro-observations often prevent major efficiency losses.

Additives work best when the process is stable

I would like to share one real time incident. The mill was running on auto mode looped with the mill outlet bucket elevator kilowatt. (KW)There was a decrease in the KW, and the mill feed was increased by the auto control (PID). After a while, the operator stopped both the feed and the mill. He asked the local operator to check the airslide between mill outlet and the elevator. They found the airslide was jammed and no material flow to the elevator!

The operator deduced the abnormality by his experience by seeing the conditions and the rate of increase of the feed by the auto control.

It’s always the human factor that adds value to the optimisation.

Grinding aids are multipliers,

not magicians.

They deliver maximum benefit only when:

• Mill ventilation is correct

• Ball charge is balanced

• Feed moisture is controlled

• Separator speed and loading are improved

• Blaine targets are realistic

Without these fundamentals, even advanced additives may become costly investments. The operator is responsible for ensuring process stability, whether using a ball mill or a vertical mill. After ensuring the system is stable, the operator observes it briefly before transitioning to automatic control. If there is any anomaly in the system the operator at once takes control of the system, stabilises and bring back to auto control.

Skilled operators adapt in real time

It will be interesting to note that the operators who operate from local panel start to operate from DCS also. They have the experience and the ability to adapt the changes. Operator checks each parameter deeply. Any meagre change in the parameters is also visible to him.

Raw materials change. Weather changes. Wear patterns change.

A skilled operator adjusts:

• Feed rate

• Water injection

• Separator speed

• Grinding pressure (in VRMs)

• Mill load distribution.

These adjustments require intuition built from years of experience, something no additive can replicate.

Human insight prevents over reliance on additives

Plants sometimes increase additive dosage to mask deeper issues like:

• Poor clinker quality

• Inadequate drying capacity

• Incorrect ball gradation

• High residue due to worn separator internals.

A knowledgeable operator finds root causes instead of chasing temporary chemical fixes.

The real optimisation sweet spot is reached when:

• Operators understand how additives interact with their specific mill.

• Additive suppliers collaborate with plant teams.

• Process data is interpreted by humans who know the mill’s behaviour.

This constructive collaboration consistently delivers:

• Lower kWh/t

• Higher throughput

• Better product consistency

• Optimum standard deviation.

Advanced additives are powerful tools, but they are not substitutes for human ability. Grinding optimisation is ultimately a human driven discipline, where skilled operators make the difference between average performance and world class efficiency. Additives enhance the process but operators

control it.

About the author:

Ponnusamy Sampathkumar, Consultant – Process Optimisation and Training, is a seasoned cement process consultant with 43+ years of global experience in plant operations, process optimisation, refractory management, safety systems and training multicultural teams across international cement plants.

Concrete

Redefining Efficiency with Digitalisation

Published

2 weeks agoon

February 20, 2026By

admin

Professor Procyon Mukherjee discusses how as the cement industry accelerates its shift towards digitalisation, data-driven technologies are becoming the mainstay of sustainability and control across the value chain.

The cement industry, long perceived as traditional and resistant to change, is undergoing a profound transformation driven by digital technologies. As global infrastructure demand grows alongside increasing pressure to decarbonise and improve productivity, cement manufacturers are adopting data-centric tools to enhance performance across the value chain. Nowhere is this shift more impactful than in grinding, which is the energy-intensive final stage of cement production, and in the materials that make grinding more efficient: grinding media and grinding aids.

The imperative for digitalisation

Cement production accounts for roughly 7 per cent to 8 per cent of global CO2 emissions, largely due to the energy intensity of clinker production and grinding processes. Digital solutions, such as AI-driven process controls and digital twins, are helping plants improve stability, cut fuel use and reduce emissions while maintaining consistent product quality. In one deployment alongside ABB’s process controls at a Heidelberg plant in Czechia, AI tools cut fuel use by 4 per cent and emissions by 2 per cent, while also improving operational stability.

Digitalisation in cement manufacturing encompasses a suite of technologies, broadly termed as Industrial Internet of Things (IIoT), AI and machine learning, predictive analytics, cloud-based platforms, advanced process control and digital twins, each playing a role in optimising various stages of production from quarrying to despatch.

Grinding: The crucible of efficiency and cost

Of all the stages in cement production, grinding is among the most energy-intensive, historically consuming large amounts of electricity and representing a significant portion of plant operating costs. As a result, optimising grinding operations has become central to digital transformation strategies.

Modern digital systems are transforming grinding mills from mechanical workhorses into intelligent, interconnected assets. Sensors throughout the mill measure parameters such as mill load, vibration, mill speed, particle size distribution, and power consumption. This real-time data, fed into machine learning and advanced process control (APC) systems, can dynamically adjust operating conditions to maintain optimal throughput and energy usage.

For example, advanced grinding systems now predict inefficient conditions, such as impending mill overload, by continuously analysing acoustic and vibration signatures. The system can then proactively adjust clinker feed rates and grinding media distribution to sustain optimal conditions, reducing energy consumption and improving consistency.

Digital twins: Seeing grinding in the virtual world

One of the most transformative digital tools applied in cement grinding is the digital twin, which a real-time virtual replica of physical equipment and processes. By integrating sensor data and

process models, digital twins enable engineers to simulate process variations and run ‘what-if’

scenarios without disrupting actual production. These simulations support decisions on variables such as grinding media charge, mill speed and classifier settings, allowing optimisation of energy use and product fineness.

Digital twins have been used to optimise kilns and grinding circuits in plants worldwide, reducing unplanned downtime and allowing predictive maintenance to extend the life of expensive grinding assets.

Grinding media and grinding aids in a digital era

While digital technologies improve control and prediction, materials science innovations in grinding media and grinding aids have become equally crucial for achieving performance gains.

Grinding media, which comprise the balls or cylinders inside mills, directly influence the efficiency of clinker comminution. Traditionally composed of high-chrome cast iron or forged steel, grinding media account for nearly a quarter of global grinding media consumption by application, with efficiency improvements translating directly to lower energy intensity.

Recent advancements include ceramic and hybrid media that combine hardness and toughness to reduce wear and energy losses. For example, manufacturers such as Sanxin New Materials in China and Tosoh Corporation in Japan have developed sub-nano and zirconia media with exceptional wear resistance. Other innovations include smart media embedded with sensors to monitor wear, temperature, and impact forces in real time, enabling predictive maintenance and optimal media replacement scheduling. These digitally-enabled media solutions can increase grinding efficiency by as much as 15 per cent.

Complementing grinding media are grinding aids, which are chemical additives that improve mill throughput and reduce energy consumption by altering the surface properties of particles, trapping air, and preventing re-agglomeration. Technology leaders like SIKA AG and GCP Applied Technologies have invested in tailored grinding aids compatible with AI-driven dosing platforms that automatically adjust additive concentrations based on real-time mill conditions. Trials in South America reported throughput improvements nearing 19 per cent when integrating such digital assistive dosing with process control systems.

The integration of grinding media data and digital dosing of grinding aids moves the mill closer to a self-optimising system, where AI not only predicts media wear or energy losses but prescribes optimal interventions through automated dosing and operational adjustments.

Global case studies in digital adoption

Several cement companies around the world exemplify digital transformation in practice.

Heidelberg Materials has deployed digital twin technologies across global plants, achieving up to 15 per cent increases in production efficiency and 20 per cent reductions in energy consumption by leveraging real-time analytics and predictive algorithms.

Holcim’s Siggenthal plant in Switzerland piloted AI controllers that autonomously adjusted kiln operations, boosting throughput while reducing specific energy consumption and emissions.

Cemex, through its AI and predictive maintenance initiatives, improved kiln availability and reduced maintenance costs by predicting failures before they occurred. Global efforts also include AI process optimisation initiatives to reduce energy consumption and environmental impact.

Challenges and the road ahead

Despite these advances, digitalisation in cement grinding faces challenges. Legacy equipment may lack sensor readiness, requiring retrofits and edge-cloud connectivity upgrades. Data governance and integration across plants and systems remains a barrier for many mid-tier producers. Yet, digital transformation statistics show momentum: more than half of cement companies have implemented IoT sensors for equipment monitoring, and digital twin adoption is growing rapidly as part of broader Industry 4.0 strategies.

Furthermore, as digital systems mature, they increasingly support sustainability goals: reduced energy use, optimised media consumption and lower greenhouse gas emissions. By embedding intelligence into grinding circuits and material inputs like grinding aids, cement manufacturers can strike a balance between efficiency and environmental stewardship.

Conclusion

Digitalisation is not merely an add-on to cement manufacturing. It is reshaping the competitive and sustainability landscape of an industry often perceived as inertia-bound. With grinding representing a nexus of energy intensity and cost, digital technologies from sensor networks and predictive analytics to digital twins offer new levers of control. When paired with innovations in grinding media and grinding aids, particularly those with embedded digital capabilities, plants can achieve unprecedented gains in efficiency, predictability and performance.

For global cement producers aiming to reduce costs and carbon footprints simultaneously, the future belongs to those who harness digital intelligence not just to monitor operations, but to optimise and evolve them continuously.

About the author:

Professor Procyon Mukherjee, ex-CPO Lafarge-Holcim India, ex-President Hindalco, ex-VP Supply Chain Novelis Europe, has been an industry leader in logistics, procurement, operations and supply chain management. His career spans 38 years starting from Philips, Alcan Inc (Indian Aluminum Company), Hindalco, Novelis and Holcim. He authored the book, ‘The Search for Value in Supply Chains’. He serves now as Visiting Professor in SP Jain Global, SIOM and as the Adjunct Professor at SBUP. He advises leading Global Firms including Consulting firms on SCM and Industrial Leadership and is a subject matter expert in aluminum and cement. An Alumnus of IIM Calcutta and Jadavpur University, he has completed the LH Senior Leadership Programme at IVEY Academy at Western University, Canada.

Concrete

Digital Pathways for Sustainable Manufacturing

Published

2 weeks agoon

February 20, 2026By

admin

Dr Y Chandri Naidu, Chief Technology Officer, Nextcem Consulting highlights how digital technologies are enabling Indian cement plants to improve efficiency, reduce emissions, and transition toward sustainable, low-carbon manufacturing.

Cement manufacturing is inherently resource- and energy-intensive due to high-temperature clinkerisation and extensive material handling and grinding operations. In India, where cement demand continues to grow in line with infrastructure development, producers must balance capacity expansion with sustainability commitments. Energy costs constitute a major share of operating expenditure, while process-related carbon dioxide emissions from limestone calcination remain unavoidable.

Traditional optimisation approaches, which are largely dependent on operator experience, static control logic and offline laboratory analysis, have reached their practical limits. This is especially evident when higher levels of alternative fuel and raw materials (AFR) are introduced or when raw material variability increases.

Digital technologies provide a systematic pathway to manage this complexity by enabling

real-time monitoring, predictive optimisation and integrated decision-making across cement manufacturing operations.

Digital cement manufacturing is enabled through a layered architecture integrating operational technology (OT) and information technology (IT). At the base are plant instrumentation, analysers, and automation systems, which generate continuous process data. This data is contextualised and analysed using advanced analytics and AI platforms, enabling predictive and prescriptive insights for operators and management.

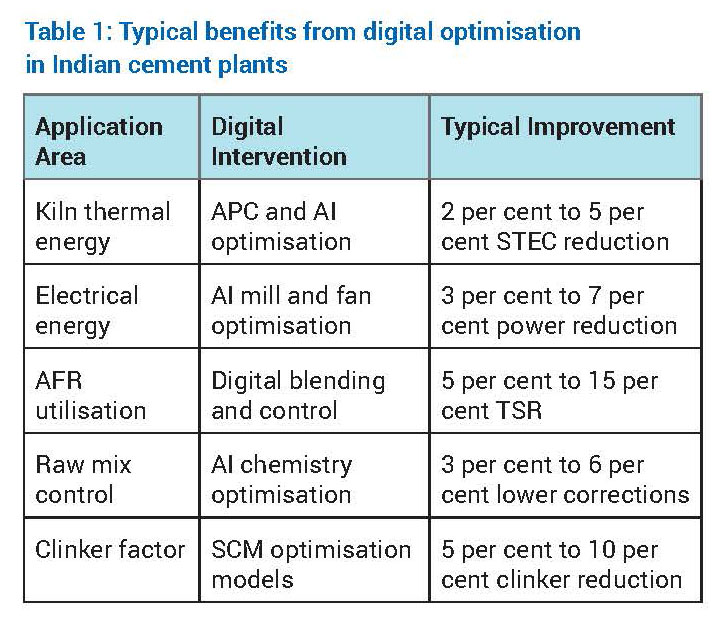

Digital optimisation of energy efficiency

- Thermal energy optimisation

The kiln and calciner system accounts for approximately 60 per cent to 65 per cent of total energy consumption in an integrated cement plant. Digital optimisation focuses on reducing specific thermal energy consumption (STEC) while maintaining clinker quality and operational stability.

Advanced Process Control (APC) stabilises critical parameters such as burning zone temperature, oxygen concentration, kiln feed rate and calciner residence time. By minimising process variability, APC reduces the need for conservative over-firing. Artificial intelligence further enhances optimisation by learning nonlinear relationships between raw mix chemistry, AFR characteristics, flame dynamics and heat consumption.

Digital twins of kiln systems allow engineers to simulate operational scenarios such as increased AFR substitution, altered burner momentum or changes in raw mix burnability without operational risk. Indian cement plants adopting these solutions typically report STEC reductions in the range of 2 per cent to 5 per cent. - Electrical energy optimisation

Electrical energy consumption in cement plants is dominated by grinding systems, fans and material transport equipment. Machine learning–based optimisation continuously adjusts mill parameters such as separator speed, grinding pressure and feed rate to minimise specific power consumption while maintaining product fineness.

Predictive maintenance analytics identify inefficiencies caused by wear, fouling or imbalance in fans and motors. Plants implementing plant-wide electrical energy optimisation typically achieve

3 per cent to 7 per cent reduction in specific power consumption, contributing to both cost savings and indirect CO2 reduction.

Digital enablement of AFR

AFR challenges in the Indian context: Indian cement plants increasingly utilise biomass, refuse-derived fuel (RDF), plastic waste and industrial by-products. However, variability in calorific value, moisture, particle size, chlorine and sulphur content introduces combustion instability, build-up formation and emission risks.

Digital AFR management: Digital platforms integrate real-time AFR quality data from online analysers with historical kiln performance data. Machine learning models predict combustion behaviour, flame stability and emission trends for different AFR combinations. Based on these predictions, fuel feed distribution, primary and secondary air ratios, and burner momentum are dynamically adjusted to ensure stable kiln operation. Digitally enabled AFR management in cement plants will result in increased thermal substitution rates by 5-15 percentage points, reduced fossil fuel dependency, and improved kiln stability.

Digital resource and raw material optimisation

Raw mix control: Raw material variability directly affects kiln operation and clinker quality. AI-driven raw mix optimisation systems continuously adjust feed proportions to maintain target chemical parameters such as Lime Saturation Factor (LSF), Silica Modulus (SM), and Alumina Modulus (AM). This reduces corrective material usage and improves kiln thermal efficiency.

Clinker factor reduction: Reducing clinker factor through supplementary cementitious materials (SCMs) such as fly ash, slag and calcined clay is a key decarbonisation lever. Digital models simulate blended cement performance, enabling optimisation of SCM proportions while maintaining strength and durability requirements.

Challenges and strategies for digital adoption

Key challenges in Indian cement plants include data quality limitations due to legacy instrumentation, resistance to algorithm-based decision-making, integration complexity across multiple OEM systems, and site-specific variability in raw materials and fuels.

Successful digital transformation requires strengthening the data foundation, prioritising high-impact use cases such as kiln APC and energy optimisation, adopting a human-in-the-loop approach, and deploying modular, scalable digital platforms with cybersecurity by design.

Future Outlook

Future digital cement plants will evolve toward autonomous optimisation, real-time carbon intensity tracking, and integration with emerging decarbonisation technologies such as carbon capture, utilisation and storage (CCUS). Digital platforms will also support ESG reporting and regulatory compliance.

Digital pathways offer a practical and scalable solution for sustainable cement manufacturing in India. By optimising energy consumption, enabling higher AFR substitution and improving resource efficiency, digital technologies deliver measurable environmental and economic benefits. With appropriate data infrastructure, organisational alignment and phased implementation, digital transformation will remain central to the Indian cement industry’s low-carbon transition.

About the author:

Dr Y Chandri Naidu is a cement industry professional with 30+ years of experience in process optimisation, quality control and quality assistance, energy conservation and sustainable manufacturing, across leading organisations including NCB, Ramco, Prism, Ultratech, HIL, NCL and Vedanta. He is known for guiding teams, developing innovative plant solutions and promoting environmentally responsible cement production. He is also passionate about mentoring professionals and advancing durable, resource efficient technologies for future of construction materials.

Merlin Prime Spaces Acquires 13,185 Sq M Land Parcel In Pune

Adani Cement and Naredco Partner to Promote Sustainable Construction

Operational Excellence Redefined!

World Cement Association Annual Conference 2026 in Bangkok

Assam Chief Minister Opens Star Cement Plant In Cachar

Merlin Prime Spaces Acquires 13,185 Sq M Land Parcel In Pune

Adani Cement and Naredco Partner to Promote Sustainable Construction

Operational Excellence Redefined!

World Cement Association Annual Conference 2026 in Bangkok

Assam Chief Minister Opens Star Cement Plant In Cachar

Trending News

-

Economy & Market4 weeks ago

Economy & Market4 weeks agoFORNNAX Appoints Dieter Jerschl as Sales Partner for Central Europe

-

Concrete2 weeks ago

Concrete2 weeks agoRefractory demands in our kiln have changed

-

Concrete2 weeks ago

Concrete2 weeks agoDigital supply chain visibility is critical

-

Concrete2 weeks ago

Concrete2 weeks agoOur strategy is to establish reliable local partnerships