Product development

A realisable dream

Published

8 years agoon

By

admin

India’s ambitious ‘housing for all’ scheme is bumping up against some harsh realities.

Prime Minister Narendra Modi had mandated affordable housing for all (read slum-residents, lower-income group and middle-class income group beneficiaries, who would be provided subsidised homes and interest subsidies to place homes at reasonable market values) in India as target for achievement between June 2015 and 2022.

This is expected to create two crore odd homes for those without a house of their own in India’s urban centers. Pegged at two crore homes by 2022, the intended phase I milestone ended in March this year and was expected to cover 100 cities as identified by the respective states.

Chairman of the Real Estate Regulatory Authority (RERA) Gautam Chatterjee is enthused by the target timeline-based policy that hinges on four verticals of a) Using land as a resource for slum rehabilitation through private developers b) Credit linked subsidy for weaker sections c) Affordable housing for the middle income groups through public and private sectors and d) Subsidy system for individual house construction.

The RERA chief, who is on a fast track of clearing housing related litigation mostly involving home buyers and developers (525 rulings issued already by RERA since July when it came into being) says, "The government is trying to rope in the private sector players which has the requisite capability and strength, but has lacked the intention right uptill now, to partner with the state and deliver a product according to the need of the situation.This capacity (for building mass homes) doesn’t not exist within the government machinery. Let’s just forget government machinery being able to be the creator on such a scale to accomplish two crore homes. The City and Industrial Development Corporation (CIDCO), Maharashtra Housing and Area Development Authority (MHADA) and statutory bodies across the country, put together, cater to only two to five per cent of the total need in the country for housing."

He adds, "Clubbed with the present situation in the market, where there is a huge unsold inventory of various luxury segments that they (private developers) have been targeting all this time, this is the most opportune time for such an initiative. The government has not targeted investors who have run away from the market, that is waiting up on self correction to boost market demand for some time now. So, since there exists a market with a need for affordable housing by a particular segment of the population, and the government is coming forward through interest subsuming as well as direct subsidy, besides being willing to partner with the private sector. This is the most important juncture (in the real estate industry) and the private sector should grab this opportunity and if possible it (mass affordable housing) will happen."

Bolstering Chatterjee’s opinion on the realty situation is Dr Samantak Das, the Chief Economist and National Director (research) with Knight Frank India, whose latest research on the realty sector shows a sharp fall in realty prices in India’s financial capital of Mumbai.

Says Dr Das, "For the first time in this decade the Mumbai market has experienced a drop in residential prices. Unlike the conventional narrative developers cut down prices to offload their unsold inventory. The base price has come down by 5 per cent which translates into an effective price benefit of 11-12 per cent for buyers. This includes bouquet of incentives such as waivers on stamp duty, floor rise and assured rental schemes. In addition we have observed that the retail inflation has been growing higher than the city price which provides an additional benefit to buyers as far as house price is concerned. The trend stems from the periodic deterioration of the market’s health with launches coming to a grinding halt. In terms of sales the Mumbai market recorded 19% uptick in H2 2017 over the demonetisation-hit same period last year, however overall sales volumes reflect a declining pattern."

National President of NAREDCO Niranjan Hirandani described the Pradhan Mantri Awas Yojana and Housing for All policy as, "Works in progress". Says he, "The policy is in place although the implementation has been rather slow. But things are picking up. Various state government are taking due steps to make this a reality, and the Central Government has done much in recent times to ensure the process has sped up."

He adds, "The steps taken in the wake of the ambitious scheme are as follows: (i) Affordable Housing was given Infrastructure status in Budget 2017; (ii) Credit Linked Subsidy Scheme (CLSS) to provide loans at much lower interest rates was set up; (iii) The Indian Cabinet approved an increase in carpet area for houses eligible under the CLSS for the Middle Income Group; (iv) The International Finance Corporation (IFC), which is a member of the World Bank Group, and mortgage lender HDFC have partnered to create a USD 800-million-dollar fund to finance the construction of affordable houses; (v) The Ministry of Housing and Urban Affairs has communicated with state/UT governments to adopt alternative, sustainable and innovative technologies for faster construction of affordable houses and finally, (vi) utilisation of Transfer of Development Rights (TDR) as a mechanism to acquire speedy acquisition of land for developing infrastructure, as also allowing developers to unlock land potential by in-situ rehabilitation of slums. So yes, the government is working towards the mission of ‘Housing for All by 2022’."

In September 2017, Union Minister of Housing & Urban Affairs Hardeep Singh Puri, announced a new public-private partnership (PPP) policy for affordable housing that allows extending central assistance of up to Rs 2.50 lakh per each house to be built by private builders even on private lands. Under this policy, eight PPP (Public Private Partnership) models have been provided for private sector to invest in affordable housing segment. It has also opened potential for private investments in affordable housing projects on government lands in urban areas.

Hiranandani cautions about the challenges ahead and says, "Affordable Housing for All by 2022′ is not without challenges. One of the biggest challenges is scarcity of land, especially in urban areas – and absolutely in the Metro Cities. This, along with other challenges, has resulted in delays in the progress of the mission. While ‘Ease of Doing Business’ is fine, approval delays still lead to delays in completing projects, which results in increased project costs and impacts affordability."

He adds, "Increasing the personal income tax limit to Rs 600,000 as the Lower Income Group (LIG) category falls in this segment. LIG being the one of the most important categories in ‘affordable housing’ segment, it’s important that the Government gives them this tax relief. This will ensure that the tax amount saved can then be invested in paying home loan EMI’s of affordable homes which they can think of buying. In addition, this will be a great step in making the Prime Minister’s mission of ‘Housing for All by 2020’ a grand success. Real Estate Sector should be allotted ‘Infrastructure’ status. This will lead to construction funds being available to the developer at much lower interest rates. This is eventually going to benefit the end customers from economically weaker section (EWS) and lower income group (LIG) as the developers would be in a position of making the projects really ‘affordable’ in its true sense.

Finally, the government must ensure that large steel companies do not face the shortage of raw materials by providing them the required support. This will lead in a sustainable and price-stable supply of steel ensuring speedy progress in the construction activity thereby assisting in completing the projects on-time with is now a compliance requirement as per RERA guidelines. Also, some concrete steps are needed to be taken to ‘insulate’ steel and cement prices.

Only Namdeo Govind Dendge, who lives on the street in south Mumbai’s busy roads, is not convinced, "As far as we (street dwellers) are concerned, we fall in the blind spot of whichever government is in place in India. The government does not have a humane way of surveying all those in dire need of accommodation. Whether the Housing for all scheme results in a house for me and my family or not remains to be seen. What I, and scores of people like me, are experiencing today is the harsh side of the government. (Like the Housing for All policy brought into force in 2015) They brought in a legislation to protect hawkers in the country in 2015 and today we are being driven out of the very streets that earned us a dignified life, despite living on the streets. What should we do now to earn a living? Where should we go?"

On cue with this strain of thought is retired town planner and Indian Administrative Service (IAS) officer Ashok Sinha (who has served on CIDCO and as divisional commissioner of the Konkan Railways amongst other posts), who says, "We are a country that has struggled with the task of creating enough number of toilets and drinking water schemes for years together, with limited success. Similar efforts at creating affordable housing were tried out even in the early 80s as well, although with varying degrees of success. Traditionally, such projects have stop short of achieving housing for the poorest sections in the past. The identified sites of the projects were ideally suited to the developers and not the intended beneficiaries. For instance when small size tenements were mandated to cater to lower segments and even middle class households in Mumbai, the developers simply capitalise on the schemes and create homes in the prescribed smaller unit sizes, but prefer to sell it to the rich as a combined package of three to four units instead."

"Even the intended beneficiaries face challenges. For instance if some persons being targeted for cheap housing like househel or daily wage earners are given accommodation in an inappropriate place of project that is far away from their place of work, it would become difficult for these beneficiaries to resist the temptation to sell of their abodes and revert back to their original shanties for work reasons.

Similarly, for some beneficiaries a house may not be their most important priority in sync with the time the government is keen to create affordable housing stock for their interest, so they may still sell their affordable home to say finance a marriage or even a business venture that may fail. Even for the middle class, an affordable housing project at Khopoli may at best be interesting as a second home. Or some journalists may have been given state subsidized homes, but found appropriate to sell them off to finance say, their child’s education and the intention of the project would be defeated."

As a solution Sinha advises, "The first phase of the Housing for All project should identify and prioritise servicing the housing needs to those who are seeking housing as their first priority. Secondly, all such housing projects should should be packaged as community projects, and not restricted to cold accommodation without the requisite social and physical components. At CIDCO community building was not the norm, but rather the exception where CIDCO may have constructed say a small educational facility, or temple or even medical centre only out of compulsion and in the wake of unrest and agitations by the project affected persons (PAPs). I remember at CIDCO, taking charge ten years after the project was initiated and I was still handing over the physical possession of some homes to intendant beneficiaries of a decade ago."

CIDCO was never a model agency that constructed low cost houses as it only planned the scheme through a limited coverage perspective says Sinha and adds, "The basic premise is ‘planning for life’ when undertaking such projects of affordable housing. Today the CIDCO creation of New Mumbai has 50 per cent of its population travelling to work to Mumbai daily. Has the intended purpose of distressing Mumbai city worked? The idea should not be to fight established norms. Don’t think of the ideal home. The strategy should be to make the commute of these 50 per cent commuters easier to give them a quality living."

He adds, "There was a Site and Services Scheme (SSS) that established that no technically constructed house can fullfill the explained need of the poor. They are organic creatures. You cannot give them mere RCC constructions or ’round shaped igloos’ as an end all. They would promptly abandon the igloo and set up a cloth tent right outside the igloo itself. There has to be a constant watch over the changing needs and what we are able to supply. With reasonable planning and a perspective of say 20 years housing for all can be achieved. We should consider this (2015 to 2022)as the first phase. There is still need for discussing genuine concerns of all stakeholders and organisations."

Agreeing with this the RERA chief says, "Townships have to be created failing which affordable transport options and links connecting to these homes will need to be created if the project has to succeed on such a large scale."– RENNI ABRAHAM

Economy & Market

Power Build’s Core Gear Series

Published

19 hours agoon

February 19, 2026By

admin

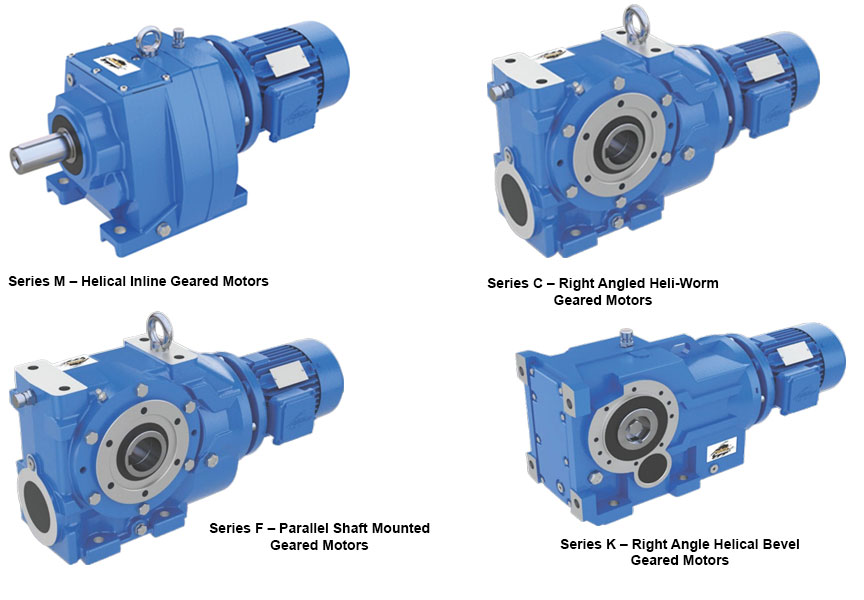

A deep dive into Core Gear Series of products M, C, F and K, by Power Build, and how they represent precision in motion.

At the heart of every high-performance industrial system lies the need for robust, reliable, and efficient power transmission. Power Build answers this need with its flagship geared motor series: M, C, F and K. Each series is meticulously engineered to serve specific operational demands while maintaining the universal promise of durability, efficiency, and performance.

Series M – Helical Inline Geared Motors

Compact and powerful, the Series M delivers exceptional drive solutions for a broad range of applications. With power handling up to 160kW and torque capacity reaching 20,000 Nm, it is the trusted solution for industries requiring quiet operation, high efficiency, and space-saving design. Series M is available with multiple mounting and motor options, making it a versatile choice for manufacturers and OEMs globally.

Series C – Right Angled Heli-Worm Geared Motors

Combining the benefits of helical and worm gearing, the Series C is designed for right-angled power transmission. With gear ratios of up to 16,000:1 and torque capacities of up to 10,000 Nm, this series is optimal for applications demanding precision in compact spaces. Industries looking for a smooth, low-noise operation with maximum torque efficiency rely on Series C for dependable performance.

Series F – Parallel Shaft Mounted Geared Motors

Built for endurance in the most demanding environments, Series F is widely adopted in steel plants, hoists, cranes and heavy-duty conveyors. Offering torque up to 10,000 Nm and high gear ratios up to 20,000:1, this product features an integral torque arm and diverse output configurations to meet industry-specific challenges head-on.

Series K – Right Angle Helical Bevel Geared Motors

For industries seeking high efficiency and torque-heavy performance, Series K is the answer. This right-angled geared motor series delivers torque up to 50,000 Nm, making it a preferred choice in core infrastructure sectors such as cement, power, mining and material handling. Its flexibility in mounting and broad motor options offer engineers the freedom in design and reliability in execution.

Together, these four series reflect Power Build’s commitment to excellence in mechanical power transmission. From compact inline designs to robust right-angle drives, each geared motor is a result of decades of engineering innovation, customer-focused design and field-tested reliability. Whether the requirement is speed control, torque multiplication or space efficiency, Radicon’s Series M, C, F and K stand as trusted powerhouses for global industries.

http://www.powerbuild.in

Call: +919727719344

Economy & Market

Conveyor belts are a vital link in the supply chain

Published

8 months agoon

June 16, 2025By

admin

Kamlesh Jain, Managing Director, Elastocon, discusses how the brand delivers high-performance, customised conveyor belt solutions for demanding industries like cement, mining, and logistics, while embracing innovation, automation, and sustainability.

In today’s rapidly evolving industrial landscape, efficient material handling isn’t just a necessity—it’s a competitive advantage. As industries such as mining, cement, steel and logistics push for higher productivity, automation, and sustainability, the humble conveyor belt has taken on a mission-critical role. In this exclusive interview, Kamlesh Jain, Managing Director, Elastocon, discusses how the company is innovating for tougher terrains, smarter systems and a greener tomorrow.

Brief us about your company – in terms of its offerings, manufacturing facilities, and the key end-user industries it serves.

Elastocon, a flagship brand of the Royal Group, is a trusted name in the conveyor belt manufacturing industry. Under the brand name ELASTOCON, the company produces both open-end and endless belts, offering tailor-made solutions to some of the most demanding sectors such as cement, steel, power, mining, fertiliser, and logistics. Every belt is meticulously engineered—from fabric selection to material composition—to ensure optimal performance in tough working conditions. With advanced manufacturing facilities and strict quality protocols, Elastocon continues to deliver high-performance conveyor solutions designed for durability, safety, and efficiency.

How is the group addressing the needs for efficient material handling?

Efficient material handling is the backbone of any industrial operation. At Elastocon, our engineering philosophy revolves around creating belts that deliver consistent performance, long operational life, and minimal maintenance. We focus on key performance parameters such as tensile strength, abrasion resistance, tear strength, and low elongation at working tension. Our belts are designed to offer superior bonding between plies and covers, which directly impacts their life and reliability. We also support clients

with maintenance manuals and technical advice, helping them improve their system’s productivity and reduce downtime.

How critical are conveyor belts in ensuring seamless material handling?

Conveyor belts are a vital link in the supply chain across industries. In sectors like mining, cement, steel, and logistics, they facilitate the efficient movement of materials and help maintain uninterrupted production flows. At Elastocon, we recognise the crucial role of belts in minimising breakdowns and increasing plant uptime. Our belts are built to endure abrasive, high-temperature, or high-load environments. We also advocate proper system maintenance, including correct belt storage, jointing, roller alignment, and idler checks, to ensure smooth and centered belt movement, reducing operational interruptions.

What are the key market and demand drivers for the conveyor belt industry?

The growth of the conveyor belt industry is closely tied to infrastructure development, increased automation, and the push for higher operational efficiency. As industries strive to reduce labor dependency and improve productivity, there is a growing demand for advanced material handling systems. Customers today seek not just reliability, but also cost-effectiveness and technical superiority in the belts they choose. Enhanced product aesthetics and innovation in design are also becoming significant differentiators. These trends are pushing manufacturers to evolve continuously, and Elastocon is leading the way with customer-centric product development.

How does Elastocon address the diverse and evolving requirements of these sectors?

Our strength lies in offering a broad and technically advanced product portfolio that serves various industries. For general-purpose applications, our M24 and DINX/W grade belts offer excellent abrasion resistance, especially for RMHS and cement plants. For high-temperature operations, we provide HR and SHR T2 grade belts, as well as our flagship PYROCON and PYROKING belts, which can withstand extreme heat—up to 250°C continuous and even 400°C peak—thanks to advanced EPM polymers.

We also cater to sectors with specialised needs. For fire-prone environments like underground mining, we offer fire-resistant belts certified to IS 1891 Part V, ISO 340, and MSHA standards. Our OR-grade belts are designed for oil and chemical resistance, making them ideal for fertiliser and chemical industries. In high-moisture applications like food and agriculture, our MR-grade belts ensure optimal performance. This diverse range enables us to meet customer-specific challenges with precision and efficiency.

What core advantages does Elastocon offer that differentiate it from competitors?

Elastocon stands out due to its deep commitment to quality, innovation, and customer satisfaction. Every belt is customised to the client’s requirements, supported by a strong R&D foundation that keeps us aligned with global standards and trends. Our customer support doesn’t end at product delivery—we provide ongoing technical assistance and after-sales service that help clients maximise the value of their investments. Moreover, our focus on compliance and certifications ensures our belts meet stringent national and international safety and performance standards, giving customers added confidence.

How is Elastocon gearing up to meet its customers’ evolving needs?

We are conscious of the shift towards greener and smarter manufacturing practices. Elastocon is embracing sustainability by incorporating eco-friendly materials and energy-efficient manufacturing techniques. In parallel, we are developing belts that seamlessly integrate with automated systems and smart industrial platforms. Our vision is to make our products not just high-performing but also future-ready—aligned with global sustainability goals and compatible with emerging technologies in industrial automation and predictive maintenance.

What trends do you foresee shaping the future of the conveyor belt industry?

The conveyor belt industry is undergoing a significant transformation. As Industry 4.0 principles gain traction, we expect to see widespread adoption of smart belts equipped with sensors for real-time monitoring, diagnostics, and predictive maintenance. The demand for recyclable materials and sustainable designs will continue to grow. Furthermore, industry-specific customisation will increasingly replace standardisation, and belts will be expected to do more than just transport material—they will be integrated into intelligent production systems. Elastocon is already investing in these future-focused areas to stay ahead of the curve.

Advertising or branding is never about driving sales. It’s about creating brand awareness and recall. It’s about conveying the core values of your brand to your consumers. In this context, why is branding important for cement companies? As far as the customers are concerned cement is simply cement. It is precisely for this reason that branding, marketing and advertising of cement becomes crucial. Since the customer is unable to differentiate between the shades of grey, the onus of creating this awareness is carried by the brands. That explains the heavy marketing budgets, celebrity-centric commercials, emotion-invoking taglines and campaigns enunciating the many benefits of their offerings.

Marketing strategies of cement companies have undergone gradual transformation owing to the change in consumer behaviour. While TV commercials are high on humour and emotions to establish a fast connect with the customer, social media campaigns are focussed more on capturing the consumer’s attention in an over-crowded virtual world. Branding for cement companies has become a holistic growth strategy with quantifiable results. This has made brands opt for a mix package of traditional and new-age tools, such as social media. However, the hero of every marketing communication is the message, which encapsulates the unique selling points of the product. That after all is crux of the matter here.

While cement companies are effectively using marketing tools to reach out to the consumers, they need to strengthen the four Cs of the branding process – Consumer, Cost, Communication and Convenience. Putting up the right message, at the right time and at the right place for the right kind of customer demographic is of utmost importance in the long run. It is precisely for this reason that regional players are likely to have an upper hand as they rely on local language and cultural references to drive home the point. But modern marketing and branding domain is exponentially growing and it would be an interesting exercise to tabulate and analyse its impact on branding for cement.

Refractory demands in our kiln have changed

Digital supply chain visibility is critical

Redefining Efficiency with Digitalisation

Cement Additives for Improved Grinding Efficiency

Digital Pathways for Sustainable Manufacturing

Refractory demands in our kiln have changed

Digital supply chain visibility is critical

Redefining Efficiency with Digitalisation

Cement Additives for Improved Grinding Efficiency