In April 2012 Belim Makina completed the installation of a new 3000 t/d kiln line of Bartin Cimento, Turkey. Just one month later during a 48 hours test run at full production all parameters met the guarantees of IKN, who had provided the design of the complete pyro line. In addition, IKN had supplied key components like ID fan, valves, dampers, kiln drive, girth gear, kiln roller stations and the clinker cooler.

Bartin Cimento, a member of Sanko Holding, in 2010 decided to replace its old wet kiln line with state-of- the-art equipment, in order to increase production to 3.000 t/d and reduce energy consumption to the best possible level. The new line was to be placed adjacent to the existing wet kiln, which had to be maintained in operation. Upon stable production of the new line the old kiln was to be dismantled. The customer as well as Belim Makina, who was selected as EPC contractor, knew IKN well from earlier projects in Turkey and accepted its proposed solution for the pyro line as it promised operational reliability in combination with attractive process parameters. In particular, the decision to select IKN as supplier for the complete pyro line was based on process guarantees and mechanical warranties. The final solution comprised a six-stage LUCY type preheater with inline calciner, a conventional 4.2x62m 3-pier kiln and a Pendulum Cooler, which is known for its linear pendulum suspension and horizontal aeration. The calciner and kiln burners were designed for burning a mixture of pet coke and coal. In addition a modern multi-channel burner was required for the use of heavy fuel oil as an alternative during start-up.

Preheater LUCY

LUCY stands for low under pressure cyclones, a development of IKN’s sister company PSP of Czech Republic. The six-stage preheater tower rises 100 meters above ground level and accommodates amply two top cyclones followed by a single string of cyclones. The raw meal enters the preheater at the riser duct between the two top cyclones of 6 m diameter. It passes the cyclone stages C2 to C6 which are 7.5m in diameter. In line with the LUCY concept, the pressure drops and the corresponding degrees of raw meal separation decrease towards the hot gas inlet. The separated raw meal leaves the cone of the respective cyclone through steep and wide raw meal chutes equipped with flaps designed for continuous release of the meal at minimal counter flow of hot gas.

Calciner

Between cyclones C5 and C6 an inline calciner type KKN-AS with low NOx duct is installed. The preheated raw meal enters the calcining channel just above the location where the burner pipes and tertiary air ducts are attached. The lower part of the calciner has a width of 4.35m square. It ensures an efficient mixing of 4.35 m square. It ensures an efficient mixing of meal and fuel with the oxygen-rich tertiary air. The upper part of the calciner has a diameter of 4.1m. It ends in a swirl head followed by a down comer duct to the C6 inlet. Initial mixing in the bottom part and repeated mixing by the swirl head together with specified retention time care for complete fuel combustion at low oxygen surplus. Parallel to the calciner channel a so-called low NOx duct bypasses oxygen-rich tertiary air to the swirl head so that the calciner duct generates CO, which reduces a good portion of nitrogen oxides summarized as NOx. Combustion is completed in the swirl head and the down comer duct of the calciner in an oxygen rich atmosphere. The calciner burner is designed to burn any combination of petcoke or coal.

Kiln

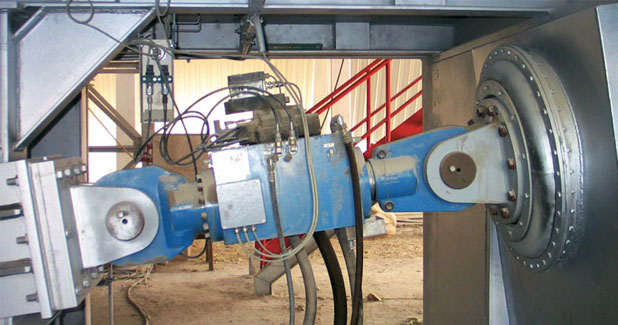

For the production of 3.000 t/d a 62m long and 4.2m shell inner diameter rotary kiln of 3 per cent inclination supported by three piers was selected. Its diameter and volume allows for a reserve in gas volume along with higher production or along with alternate fuel combustion. The 12 radial roller bearings of the kiln supplied by IKN have spherical seats for the bushes, which tolerate bending of the roller shafts and render overheating less likely. They are equipped with an oil and water distribution system for lubrication and cooling. Temperature of oil and thrust ring are monitored by thermocouples. Adjustment boxes on the frame serve for horizontal alignment during operation. For uniform wear of rollers and tires regular axial shifts of the kiln take place. A shift to its upper position is performed by a single hydraulic thrust roller pushing against the tire of bottom pier #1. The kiln is then allowed to travel down by gravity against the thrust roller, which has meanwhile returned to its lower position. The axial shifts are programmed in regular intervals of 5 – 8 hours. Shell temperatures and tire slips are monitored by scanners. Combined with proven shell materials and statics, forced axial kiln shifts and spherical roller bearings provide optimal protection against mechanical kiln failures.

The inlet and outlet seals are air cooled double lamella types, which are easily maintained.

The 55MW thermal capacity multi-channel burner is designed to burn 100 per cent pet coke, 100 per cent coal or a mixture of both. For start-up heavy fuel oil can be used through a separate fuel lance of 5.280 kg/h capacity.

Cooler

The clinker cooler still is the key to the availability and heat efficiency of the pyro line. IKN’s Pendulum Cooler has an aerated surface of 68m2. Availability is assured by a single stage, single hydraulic cylinder drive located at the front end, by Linear Pendulum Supports (LPS) with no lubricated parts within the confined area of the under grate housing, by minimal number of movable parts of the grate surface, by a slow motion roller crusher capable of handling chunks up to a size passing the kiln burner pipe and by a minimal number of 7 fans connected to 7 compartments of the 21m long grate.

Heat efficiency equal to secondary and tertiary air of high and stable temperature is assured by the clinker inlet distribution system KIDS, which with regard to the width of the 3.2m wide grate generates a clinker bed of uniform resistance against the passage of air, and by air distribution to all clinker voids by gentle horizontal COANDA aeration. Named after Henry Coanda of Romania, this effect creates horizontal air jets which are aerating the clinker bed and by keeping adjacent to the grate surface provide an efficient cooling of the grate itself. Safe cooler operation is simply limited to the observance of a pre-set bed pressure drop of the first air compartment, which is controlled by the speed of the hydraulic cylinder. Rather than close automated control, which is provided as well, IKN recommends a fixed grate speed allowing for a pre-set range of bed pressure variation. In most cases – including Bartin Cimento – fixed grate speed comes along with stable kiln operation.

Thanks to the accuracy of the grate alignment and the minimal gaps between moving and fixed parts of the grate, the amount of clinker falling into the under-grate compartments is minimal. The dust could be evacuated during annual shut downs. For comfort and safety, a tube chain conveyor is installed for the extraction of any clinker dust to the clinker discharge. Typically, the tube extractor is operated once a day for a couple of hours.

Installation

Installation of the pyro line took place from September 2011 until April 2012. During this period IKN delegated various experts for inspection of local manufacturing based on its detail drawings and for assistance of Belim Makina for speedy identification and installation of parts. The cooperation with Belim Makina was excellent as the company had earlier experience with IKN equipment.

A highlight and challenging task was the installation and alignment of the kiln girth gear. Using a crane, both halves of the girth gear were wrapped around the kiln and firmly bolted together. Upon measurements of an acceptable run-out, the crew installed the auxiliary drive, adjusted the rollers to their final position, and finalized the gear alignment. auxiliary drive, adjusted the rollers to their final position, and finalized the gear alignment. For cooler grate surface installation, preassembly tools specifically designed for this project were used, which reduced installation time and which made sure that all parts fitted easily into their position. For LPS alignment a laser-light theodolite was used and the reference points marked on the kiln foundation were protocolled for later verification.

Finally, the six-stage preheater at Bartin is the new landmark which represents the latest technology in cement production in the area.

Commissioning/Testing

In May 2012 the new pyroline was started up. Within the two days performance test the same month all relevant technical parameters were measured during operation and a protocol was signed.

Conclusions

The performance of the new pyro line at Bartin Cimento confirms that the combination of IKN Pendulum Coolers with a state-of-the-art pyro system provides excellent results. The combination leverages the IKN cooler performance to an over-all plant performance which in this case benefits Bartin +Cimento. It confirms further that for new pyro lines and refurbishment projects, excellent process know-how, in-house manufacturing capability coupled with thorough design experience provides superior results in terms of time, efficiency, and cost.

by Frank Lichomski, IKN GmbH, Germany

Design Parameters:

|

Capacity

|

3.000 tpd

|

| Preheater |

6 stage single string type LUCY with inline calciner (KKN-AS) |

| Calciner burner |

"for 100% petcoke, 100% coal or mixture of both alternatively 100% HFO" |

| Kiln |

4,2m x 62 m |

| Kiln Burner |

"for 100% petcoke, 100% coal or mixture of both alternatively 100% HFO" |

| specific heat consumption |

<688 kcal/kg |

| Cooler |

"single stage with single hydraulic cylinder drive suspended by Linear Pendulum Support (LPS) aerated surface: 67 m2

installed cooling air: 2,1 Nm3/kg clinker" |

| cooler discharge clinker temperature |

65?C above ambient |

| Roller crusher |

Roll crusher with 3 rolls, width: 3m |

| Exhaust fan |

245 Nm3/h |

Economy & Market4 weeks ago

Economy & Market4 weeks ago

Concrete4 weeks ago

Concrete4 weeks ago

Economy & Market3 weeks ago

Economy & Market3 weeks ago

Concrete4 weeks ago

Concrete4 weeks ago