Concrete

Prefab Concrete: Moulding a Success Story

Published

13 years agoon

By

admin

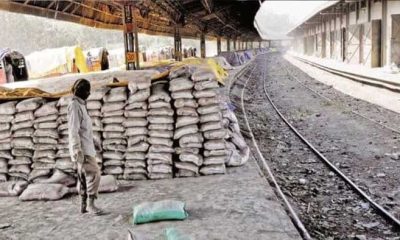

The Indian prefabricated component industry although is in a nascent stage, is fast catching attention of builders and construction companies. Even a fraction of upcoming investments in real estate and infrastructure project is spent in using prefabs would add about Rs 20,000 crore of business to the industry in next five year, from the current level of less than Rs 2,000 crore, that’s 10 times, finds FIRSTINFOCENTREHistorically, houses have been built in one place and reassembled in another and possibly the first recorded prefab house was the manning portable cottage constructed by a London carpenter, H Manning. He constructed a house that was built in components, then shipped and assembled by British emigrants. Another interesting building was the prefabricated hospital that the British Army deployed in 1855 during the Crimean War designed by Isambard Kingdom Brunel with innovations in sanitation, ventilation and ria flushing toilet.The world’s first prefabricated, pre-cast panelled apartment blocks were pioneered in Liverpool. A process was invented by city engineer John Alexander Brodie, whose inventive genius also had him inventing the football goal net. The tram stables at Walton in Liverpool followed in 1906. The idea was not extensively adopted in Britain, however was widely adopted elsewhere, particularly in Eastern Europe.Prefabricated homes were produced during the Gold Rush in the United States, when kits were produced to enable Californian prospectors to quickly construct accommodation. Homes were available in kit form by mail order in the United States in 1908."Prefabricated" refers to building built in components (eg, panels), modules (modular homes) or transportable sections (manufactured homes). Modular homes are created in sections, and then transported to the site for construction and installation. These are typically installed and treated like a regular house. Although the sections of the house are prefabricated, the sections, or modules, are put together at the construction much like a typical home.In India, the prefabricated or precast material industry is in a nascent stage. It is worth Rs 1,500 crore in infrastructure construction and less than Rs 500 crore in case of prefabricated homes. People are experimenting with them and some contractors specialise in them although there are certain drawbacks to the support system in urban area. At present, precast technology are more in vogue in rural India and not so favourable for elite housing as aesthetics may be compromised.However, of late, many builders have taken up prefabrication to meet demand. Earlier used in large projects, this system is gradually being preferred in most aspects of construction. Facing a shortage of labourers, builders are resorting to new ways to meet the unprecedented construction demand in one of the fastest growing property markets in Asia. Prefabricated building systems that have been traditionally used in India to build bridges, metro rails and industrial units so as to save money and time are now finding their way into constructing homes.Says a structure consultant, that using prefabricated materials has made construction work easy and it also brings down the construction time by as much as 50 per cent. Though using such materials is more common abroad, prefabricated structures are used in India in only large construction projects.Use of prefabricated materials has more or less become a norm in building construction in markets overseas. The trend has just started in India, because of the construction boom and western architectural influences.Now, more and more builders are opting for prefabricated materials to put together large structures without employing large labourers. Prefabricated materials are essentially ready-to-fit materials manufactured at a factory outside the construction site. They are later assembled at the construction site by masons and joiners.In prefabricated housing construction, only the foundation and floor slabs are constructed the conventional way, which involves brick work, timber work, cement and sand to the building site. Sections of walls and roof are fabricated at a factory-with or without windows and door frames attached – and transported to the site, where they are just assembled and bolted together.Prefabrication saves time and as a result cost. For instance, casting of a super structure, where the structure of a building above the ground level takes 7-28 days if the casts are made at the construction site. But if the casts are made at a plant outside the construction site, it takes just seven days.Although prefabrication is being used on a growing number of projects, most construction work is still site-based.Players in Prefabricated componentsThe cement prefabricated component industry is largely fragmented with large number of small players dominating regional business. Many producers still continue with conventional methods of production that meet local demand and specifications. Few organised players using modern technology are emerging with modest investments in plant and machinery. Couple of them also have technical tie-up with foreign specialists. Among the major players having pan-India presence is NCL Industries.NCL Prefab a division of NCL Industries, was set up in 1979. The company’s manufacturing unit is located at Jeedimetla, Hyderabad. NCL has developed its prefab housing systems by using Bison Panel. These systems are mainly used in farmhouses, dwelling houses, row houses, project houses, custom-made houses, rest houses, guest houses, hill resorts, store sheds, penthouses, security cabins, mobile check-posts, industrial sheds, disaster housing, defense barracks, school buildings and many more. Office quarters for Reliance Petroleum staffs, guest houses for Sanghi Industries in Hyderabad, office building for Arvind Mills in Ahmedabad, hill resort at Kodaikanal and a four-storey school building in Pune are some of the projects undertaken by the company using this technology.The company feels that the prefab business has really caught on, as most construction companies, army, as well as paramilitary forces, have started using them on a regular basis. While announcing the 2010-11 third quarter results K Ravi, MD of NCL Industries, stated the that company will take up construction of prefab structures in a joint venture with Austria’s VST namely, NCL VST Infra Limited. The idea is to introduce the prefab technology in India, particularly for high rise buildings. The cost of the project is estimated at Rs 21 crore and the first unit will come up in Hyderabad. Later on it will spread the technology throughout the country.The current technology limits the operations to cater to ground floors and manufacturing normal prefab shelters. Using new technology known as the formation; the shuttering material will remain in the building.Prospects and challengesThe current cement prefabricated component industry size estimated at Rs 2,000 crore, although in a nascent stage, is fast catching attention of builders and construction companies. The size has potential to grow 10 times even if a fraction of upcoming investment in real estate and infrastructure projects is spent in using prefabs. The potential sectors which can use prefabricated component are roads and bridges, railways, airports, ports, warehousing and storage housing and commercial complexes. As of end-May 2011, total investment in pipeline in these sectors was about Rs 32,400 billion. Even 0.6 per cent of this can bring in additional business of Rs 200 billion for the prefab industry. High potential segments are roads and bridges, railways, airports and ports. These four can generate more than Rs 150 billion of business alone. However, much would depend on quality of products offered, meeting specifications and timely delivery as these projects are time and cost conscious.NCL’s improved prefab systemsThe wall panel height is increased to 9 feet & 10 feet.Expanded polystyrene sheets are sandwiched between double skin panels for better thermal comfortEach panel is lipped on all sides with appropriate GI sections for easy interlocking. The lipping provided is helping to avoid damage of the edges during transport False ceiling is introduced for all most all the modelsThe roofs are provided with GI corrugated sheets or pre-painted sheets with appropriate ridge elementsDesigned eve plates are introduced at the edges of the roofs to add elegance to the sheltersElectrification for lighting and air conditioning is stream lined in the systemThe system of erection is simplified using minimum components

Concrete

JK Cement Boosts Production Capacity with New Production Line at Panna Plant

Published

1 week agoon

April 29, 2024By

admin

JK Cement hasannounced the inauguration of a new production line at its Panna Plant. This development marks a significant milestone in the company’s expansion strategy and reaffirms its commitment to meeting the growing demand for cement while setting its position as a key industry player.

The new production line at the Panna Plant effectively doubles its clinker production capacity to 6.6 million metric tons per annum (MTPA), up from the previous 3.3 MTPA. This expansion positions JK Cement to cater efficiently to the increasing demand for cement across Uttar Pradesh, Bihar, and Central India.

Dr Raghavpat Singhania, Managing Director, JK Cement Ltd., said, “JK Cement is built on a foundation of growth and expansion. Our new Panna Plant production line is a key pillar in our comprehensive business expansion plan, propelling us towards our vision of becoming a leading player in the cement industry. This strategic expansion allows us to meet the rising demand for high-quality cement, ultimately enhancing our ability to serve our customers. We remain committed to delivering value to all stakeholders and contributing to the nation’s development.”

Madhavkrishna Singhania, Deputy Managing Director and CEO, JK Cement Ltd., commented, “The launch of our new production line underscores JK Cement’s unwavering commitment to achieving long-term growth and operational excellence. This expansion empowers us to optimize production processes, unlock our full potential, and position ourselves for the future of the cement industry.”

The new production line integrates advanced automation systems for precise control and monitoring, minimising human intervention and enhancing efficiency. State-of-the-art machinery and equipment ensure optimal performance, reliability, consistent output quality, and energy efficiency, reflecting JK Cement’s commitment to sustainability. The plant incorporates energy-saving technologies, optimised kiln systems, and waste heat recovery systems to reduce energy consumption and lower the carbon footprint. Stringent quality control measures in the plant guarantee that cement products meet the highest industry standards.

Additionally, the Panna Plant expansion project generates employment opportunities, contributing to socio-economic growth in the region. JK Cement actively engages with the local community through educational, healthcare, and social initiatives, strengthening its bond with stakeholders.

With a significant investment of Rs. 2850 Cr, the Panna Plant expansion project reflects JK Cement’s vision for sustainable growth, environmental protection, and contribution to economic and social development in the region.

Concrete

Making durable concrete by using ternary blend

Published

1 week agoon

April 27, 2024By

admin

Cement, flyash, ground granulated blast furnace slag(GGBFS) are the key components in the ternary blend used to make concrete. Nagesh Veeturi and Sumanta Sahu of KEC International – Civil Business, shed light on reducing the carbon footprint of cement production by using supplementary cementitious materials.

Cement is prime ingredient in concrete. One tonne of cement produces around 0.8 to 1 MT of carbon dioxide. It’s worth noting that efforts are being made to reduce the carbon footprint of cement production by using supplementary cementitious materials such as flyash and GGBS in concrete. In case of ternary blended concrete, supplementary cementitious materials flyash and GGBS are used in addition to cement, sand, aggregate, water and admixture.

To evaluate the percentage of replacement of cement with flyash and GGBS, one needs to understand the properties of concrete mix with flyash and GGBS as ingredients, structure strength, stripping time and durability requirements.

Properties of Supplementary Cementitious Materials

Flyash

Pulverised coal is used in thermal power plants for electricity generation. A by-product of this combustion reaction is fly ash. The electrostatic precipitators (ESPs) used inside chimneys of the power plants remove flyash before ejecting out the combustion gases into the atmosphere. Fly ash is a very fine particle like residue, which has pozzolanic properties. Hence it is often blended with cement and also used as partial replacement of cement.

Fly ash consists of silica (SiO2), alumina (Al2O3) and calcium oxide (CaO) as its major components. Fly ash can be of two types – C type and F type. C type fly ash is rich in calcium oxide and possesses both cementitious and pozzolanic properties whereas F type fly ash is low in calcium oxide content and possesses only pozzolanic properties.

- Due to spherical shape of flyash, water demands in concrete is reduced, concrete becomes more cohesive.

- Silica in flyash reacts with calcium hydroxide released from cement to form CSH Gel, Formation of CSH Gel leads to increase in strength of concrete further and make the concrete dense and durable.

- 35 per cent of cement can be replaced with flyash according to IS specification. However, for mass concrete high volume flyash up to 50 per cent can be used.

- Early strength observed to be less for flyash concrete.

- Due to slow development of strength of concrete, stripping time gets delayed.

(Flyash produced from Thermal Power Plant)

Ground Granulated Blast Furnace Slag (GGBFS)

Blast furnace slag is a by-product of iron ore during iron extraction process. Amongst all mineral admixtures, blast furnace slag has the highest specific gravity (2.8 to 3.0). Typically, the slag fineness is slightly more than that of the cement.

There are various types of slag available like air cooled slag, expanded or foamed slag, granulated slag. Among these only the granulated slag is commonly used as a mineral admixture. It is a highly reactive form of slag and is usually quenched to form a hardened matter which is then grounded into particles of fineness almost same as that of cement. Hence the material is called as ‘ground granulated blast furnace slag’.

GGBFS possesses both cementitious and pozzolanic properties. An activator is needed to hydrate the slag.

- GGBFS increases the initial setting time of the concrete. But it does not alter the workability of the concrete much because its fineness is almost same as that of the cement.

- The early rate of strength gain in concrete is diminished by replacement of cement in the concrete with GGBFS.

- The final strength is improved by slag cement and also the durability of the concrete is increased.

- Concrete uses in marine construction are highly prone to chemical attack and corrosion. GGBFS as a concrete ingredient increases resistance against sulphate and chloride attack.

Normally concrete tends to segregate with GGBS as ingredient,

(GGBFS produced from Steel Plant)\

Concrete with flyash and GGBS as ingredients (Ternary Blend)

Ternary blended concrete is observed to be more cohesive and workable due to presence of flyash in concrete. Early strength gain can be achieved by using both Cement and GGBS in concrete. Concrete with ternary blend is win-win situation in terms of good product quality, optimising the cost of concrete, durability and resistance against chemical attack. Additionally, the use of SCMs in concrete can contribute to sustainability efforts by minimizing the cement content which is associated with significant carbon dioxide emission during its manufacturing process.

The hydration process of ternary blended concrete is divided into primary reaction by OPC and GGBS, pozzolanic reaction of GGBS and flyash as the secondary process. Both materials react with Calcium hydroxide produced by cement hydration to form CSH gel, which gives denser microstructure than conventional OPC concrete. The dense structure improves the durability properties of ternary blended concrete. Process yields to minimise penetration of aggressive chemicals such as sulphate, chloride as compared to conventional concrete mix.

Conclusion

Use of supplementary cementitious materials always improve the durability properties of concrete along with cost optimisation. Selection of supplementary cementitious materials, percentage replacement with cement is taken considering the strength and durability requirements of structure.

Ultratech Cement will once again use the state-of-the-art vertical roller mill technology from Gebr. Pfeiffer, to build three new clinker production lines.

As Ultratech Cement gears up for its three new clinker production lines, a corresponding follow-up order was awarded to Gebr. Pfeiffer SE, Germany, and its Indian subsidiary Gebr. Pfeiffer (India).

As the largest cement plant operator in India and one of the top ten in the world, Ultratech Cement from Mumbai, India, is contributing to shaping the future of the cement industry. At their Happy 3 plant, the cement raw material will be ground in an MVR 5000 R-4 mill. With a 5,300-kW drive, this mill can grind approx. 705 tph to a product fineness of 1.5 per cent R 212 µm. The integrated SLS 5300 VR high-efficiency classifier, with optimised flow and electrical efficiency, separates the product to achieve the target fineness.

For the grinding of approx. 45 t/h of pet coke or approx. 90 t/h of coal, three vertical roller mills of the type MPS 3550 BK will be supplied. These are equipped with a 1,300-kW gearbox, as standard. By using Pfeiffer MPS mills, Ultratech is able to process both pet coke and coal, as well as any mixture of these two materials, at the same speed of the grinding bowl, thus avoiding three expensive frequency converters. The new coal mills will be equipped with an integrated high-efficiency classifier type SLS 3750 BK of the latest design.

It is important for UltraTech’s stock of spare parts that the latest MVR mills are characterised by grinding rollers based on the R=C principle, as this brings significant advantages for the customer. It means that these mills are equipped with grinding rollers that, equipped with the corresponding grinding elements, can be used, along with the appropriate power modules, for raw meal grinding as well as for cement grinding.

As the components of rollers, grinding roller suspension system, roller arms in cement and raw mills are identical with the ones which the customer has already received from Gebr. Pfeiffer, he requires a smaller number of spare parts in stock. This is because the components mentioned can be used for all his cement and raw mills.

The MVR 5000 R-4 mill for the Happy 3 plant has four actively redundant grinding rollers and can also be operated with two grinding rollers in the event of planned or unplanned maintenance work. This mill can then still produce approximately 70 per cent of the nominal capacity, so that the cement rotary kiln can continue to be fed with raw material.

The MVR mills are equipped by Gebr. Pfeiffer with the modern systems for preventive, maintenance-oriented condition monitoring. This will enable the customer to implement modern, digital maintenance concepts. The MPS mills will be prepared to include such options at a later point in time.

Order execution will be jointly by the subsidiary Gebr. Pfeiffer (India) and Gebr. Pfeiffer SE (Germany). The entire customer support and plant engineering will be carried out by competent Pfeiffer engineers in Noida.

The core components, such as gearbox, grinding bowl, grinding roller suspension system and the grinding rollers, are supplied from Europe by Gebr. Pfeiffer SE. The remaining components, such as the foundation parts, the housings, the classifiers and most of the plant components will be provided by Gebr. Pfeiffer (India).

The Customer Support Centre in Noida, being close to the customer, will later also provide support for the plants. This can be done in real terms by sending personnel to the plants or via remote data access.

For this purpose, Gebr. Pfeiffer offers hardware and software solutions, which are supported by competent technical personnel during normal office hours, if possible, in the local language. The picture shows an MVR mill of similar size (Type MVR 5000 R-4).

JK Cement Boosts Production Capacity with New Production Line at Panna Plant

Making durable concrete by using ternary blend

Ultratech sources VRM from Gebr. Pfeiffer

RAHSTA to showcase cutting-edge road construction tech, says NCC Director

RAHSTA will drive road construction innovation: Sundaresan

Environment Ministry revises rules of solid waste management

M-sand boards new terrain

Concrete: A Highly Sustainable Building Material

Process and quality optimization in cement plant.