Technology

Rising up to Application Demands

Published

5 years agoon

By

admin

Innovation is an ongoing process for G&D equipment manufacturers, where meeting application demands and trying to overcome common challenges is a priority.

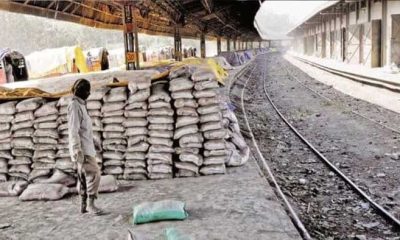

Gears, drives and transmission systems form a vital component in any manufacturing set up, and cement is no exception. In fact, cement sector is a special customer of the gear manufacturers, because it perhaps uses the widest range of gears from smallest to biggest, and sometimes poses the most formidable challenge to the transmission industry as it pushes the frontiers of technology in terms of transmitting large power ratings.

Range

The equipment manufacturers are providing a wide range of options for all applications for the cement manufacturer to choose from as far as gears, drives and transmission equipment is concerned. Power Build has a very wide range of products when it comes to the small and medium size of power transmission solutions under different series – Inline helical geared motor, Parallel shaft geared motor, Heli-bevel geared motor, Heli-worm geared motor, SMSR (shaft mounted speed reducer), and Planetary gear box/geared motor.

Gebr. Pfeiffer provides vertical mills with MultiDrive? . The MultiDrive, which has proven successful in industrial operation since 2008, was developed by Gebr. Pfeiffer in cooperation with Siemens/Flender especially for the MVR mill, Gebr. Pfeiffer claims. Gebr. Pfeiffer claims that apart from incorporating several innovative processes, MultiDrive technology offers various systems that avoid main damages occurring in conventional planetary gearboxes, like – drive arranged under the grinding bowl; weak spots; and downtime with active redundancy in the process. "The intelligent design of the MultiDrive? perfectly fits the MVR (vertical roller mill) mill because with both elements together, active redundancy is ensured for the mill drive and grinding rollers. Up to six independent drive units, each comprising an electric motor and gear, engage with a girth gear flanged to the neck of the grinding table transmitting their torques to the latter."

"For maintenance purposes or in the unlikely event that a failure should occur, one or several drive units can be disengaged, without causing a stop of production. This is a protection against total failure," Gebr. Pfeiffer added.

Performance parameters

There are several parameters that highlight the performance superiority of gears and drives equipment. R Haridoss, Vice President (Sales & Marketing), Power Build Private Limited, emphasises that it was not just the torque and speed, but the reliability of the geared motor was the key as it defines the performance of the machine or equipment in a process industry.

In cement industry, while considering large and extra-large capacity solutions, the most important point for grinding raw material, cement and granulated blast-furnace slag is: Maximum throughput and utmost technical availability," says Gebr. Pfeiffer. With a drive power of up to 18,000 kW, throughput rates of more than 1,400 tons/hour can be reached on a single mill. An additional important feature of this system is the double active redundancy ensuring highest availability and productivity without downtime.

Innovation

Gebr. Pfeiffer through its MultiDrive technology developed active redundancy of drive system as a protection against total failure as mentioned in its features earlier (six independent drive units). Another important feature of this type of drive is: delicate gearbox components are not located under the grinding table, thus ensuring an unparalleled technical availability of the drive system. In case a drive unit fails, which is rather improbable, the unit concerned can be taken out of the system, with the others still operating, so that the mill will continue producing, sometimes even without a reduction of throughput.

With adapted combination of Pfeiffer MVR mill and MultiDrive?, higher production rates can be achieved for which normally two vertical mills operating in parallel may be required, Gebr. Pfeiffer claims.

Power Build has been continuously developing new products to meet the application demands of the market. One of the recent developments is motodrive and planetary drives, says Haridoss. Motodrive is a combination of gear box, motor and a variable frequency inverter mounted on the motor itself. The applications like weigh feeders, conveyors and intralogistic conveyor wherein motodrive is widely used.

On the other hand, planetary gear box is an ideal solution for inline and right-angled applications, which require high ratios up to 2,500:1 in a limited space. The current product range covers 65,000 N-m. The product has a range of options on the output side to suit the customer needs.

"Also, we are in the process of introducing Servo suitable gearboxes, geared motors with cabinet mounted variable frequency drive (VFD), custom build gear boxes and geared motors for various applications, specialised planetary drives etc., for cement and other industries," says Haridoss.

O&M practices

Most of the gears and drives equipment manufacturers also follow the practice of providing preventive maintenance and training the operators of the user manufacturers as part of building long term relationship with the latter. "Imparting customer training for operation and periodic maintenance can enhance the customer confidence and drive value additional business," says Haridoss.

For ensuring high energy efficiency, Power Build also offers solutions with higher efficiency IE2/IE3 geared motors, suitable to run through VFD with soft starting and optimised product selection can keep check on the overall electricity consumption. This could help industry to earn carbon credit, Haridoss claims.

Looking ahead

Growth in cement segment has been moderate in the last couple of years, mainly because of over-expansion in capacity of cement plants when the demand growth was moderate since 2010. The capacity utilisation of the industry hovered around or below 60 per cent for several years during this period, which has seen a rising trend only over the last fiscal, when the consumption growth touched 12-13 per cent according to estimates.

"We are anticipating good business in the next three years as a lot of infrastructure projects are lined up. The Indian Government has also initiated many projects in rail, road and housing segments," says Haridoss.

Power Build had been witnessing equal demand from new project orders and replacement orders in the recent years.

You may like

Economy & Market

We are shaping the future of clean air

Published

2 days agoon

April 16, 2024By

admin

Monil Parikh, Managing Director, Techflow Enterprises Pvt Ltd, leads us to a better understanding of how cutting-edge designs and advanced technologies are revolutionising the process of filtration, driving efficiency and environmental responsibility within the cement sector.

Tell us about your air pollution control systems.

Techflow Enterprises, operating from our expansive 30,000 sq m facility, which is one of India’s largest, manufactures a comprehensive suite of air pollution control systems specifically designed for cement plants. Our solutions include:

Pulse Jet Bag Filters: Employing compressed air for efficient cleaning, these capture fine dust particles generated during grinding and packing. Techflow’s bag filters are designed to restrict the outlet emission up to 5mg/Nm3.

Electrostatic Precipitators (ESPs): Ideal for ultra-fine particulate matter in kiln exhaust gases, ESPs utilise an electric field for superior dust capture with 99.9 per cent capacity.

Centrifugal Fans: We offer various fans like induced draft (ID) fans for draft creation, process fans for dust-laden air transport, and kiln fans for high-temperature gas streams.

Techflow’s commitment to quality is evident in our proven track record. We are actively supplying solutions to leading cement players like Adani Cements, Ambuja and ACC Cement, Dalmia Bharat Cement and Wonder Cement. Our installations across India and Asia stand as a testament to our expertise in handling cement plant dust control challenges.

How do your products and systems integrate with cement plants?

Techflow’s air pollution control systems seamlessly integrate into your existing cement plant. Our pulse jet bag filters fit effortlessly downstream of grinding mills and packing stations, effectively capturing fine dust particles generated during these processes. Electrostatic Precipitators (ESPs) excel in kiln exit gas streams, working alongside existing cyclones to achieve ultra-fine particulate control, a critical step in maintaining clean air emissions.

Techflow’s comprehensive offering of centrifugal fans ensures a perfect fit for any application. Our ID fans seamlessly integrate into the kiln system, creating the necessary draft to pull exhaust gases through the air pollution control equipment. Process fans, strategically placed throughout the plant, efficiently convey dust-laden air from various generation points, like clinker coolers and raw material handling, towards the filtration units. This modular approach minimises disruption during installation and ensures optimal dust collection across your entire cement production process.

How do your innovative designs better the process of filtration at cement plants bringing efficiency to the process?

Techflow’s commitment to innovation translates to superior filtration efficiency and operational cost savings for cement plants. Our pulse jet bag filters incorporate features like:

- High-efficiency filter media: Designed for specific dust types, this media minimises pressure drop across the filter, reducing energy consumption.

- Improved flue gas entry design

- Low Pressure Cleaning Systems

- Optimised pulse cleaning systems: These systems efficiently dislodge dust cake buildup using compressed air, maximising filter media life, and minimising downtime.

Our ESPs utilise advanced electrode designs to enhance particle collection and reduce maintenance intervals. Furthermore, Techflow’s centrifugal fans are meticulously crafted for superior aerodynamic performance, leading to lower energy consumption and improved overall plant efficiency.

Techflow has developed a SMART-LINK automation module for better maintenance and real-time remote tracking of performance of each equipment. Cement plants equipped with Techflow’s systems experience reduced operational costs, minimised downtime and compliance with ever-evolving environmental regulations.

What is the key differentiator between traditional filters and modern filters?

Traditional bag filter systems often relied on manual cleaning methods, leading to inconsistent performance, increased downtime, and potential worker exposure to dust. Modern pulse jet bag filters, like those offered by Techflow, address these limitations.

Our systems leverage automated cleaning mechanisms, ensuring consistent filtration efficiency and minimal operator intervention. Additionally, advanced filter media materials in Techflow’s bag filters offer superior dust capture capabilities compared to traditional fabric filters.

This commitment to modern technology translates to a safer and more efficient and environmentally friendly dust control solution for cement plants.

Can your designs be customised as per the requirement of the customers?

At Techflow, we understand that every cement plant has unique dust control requirements. That is why we prioritise customisation across our entire product range:

Pulse Jet Bag Filters: Filter media type and micron rating based on dust properties, number of filter bags, and pulse cleaning system configuration like cycle time and pressure can all be adjusted to optimise performance for your specific dust and airflow. The system can be designed to achieve less than 5mg/Nm3 outlet emission standards as well.

- Electrostatic Precipitators (ESP): ESP design can be customised with features like the number of electrode rows, electrode spacing, and power input like voltage and current to achieve the desired dust collection efficiency for your specific outlet emission capacity less than 20mg/Nm3.

- Centrifugal Fans: Fan designs are tailored by adjusting factors like impeller diameter, blade design, and motor size to meet the specific pressure and flow requirements of various processes within a cement plant.

This focus on customisation ensures Techflow’s air pollution control systems perfectly match your cement plant’s needs, guaranteeing optimal dust capture and efficient operation.

What is the role of technology and automation in building filtration systems?

Techflow has designed a SMART-LINK System that can be integrated to our equipment which tracks and monitors performance of equipment in real time.

- Continuous diagnostics

- Condition-based maintenance

- Prevention of unplanned downtime

- Early problem detection using AI

- Data collection for process optimisation and efficiency maximisation

- Auto alert with warning driving timely human interactions

- Remote maintenance assistance by Techflow Team.

What are the major challenges in the filtration process and your system integration at cement plants?

The cement industry’s focus on sustainability, higher production and diverse fuel sources creates filtration hurdles. Adapting to changing dust properties, handling increased dust loads, and integrating seamlessly within space constraints are key challenges.

Techflow tackles these issues through advanced design techniques, exploration of innovative filter media, and modular system design. This ensures our filtration systems remain adaptable, efficient and seamlessly integrated within your cement plant, empowering your success.

How do you plan to further better your products and bring innovation in the future?

At Techflow, we are not just building filtration systems, we are shaping the future of clean air in the Indian cement industry. After successful expansion of the manufacturing facility in 2023, now it is time to improve designs and process optimisation. The future holds exciting possibilities: next-generation filter media with self-cleaning properties and

extended lifespans, minimising maintenance and maximising efficiency.

Techflow’s legendary after-sales support is about to get even better. We are expanding our global service network to provide you with 24/7 access to a team of India’s most experienced filtration specialists, ensuring your system operates flawlessly throughout its lifecycle.

Together, we will lead the way towards a sustainable future, paving the path for a greener tomorrow with green cement.

- –Kanika Mathur

Economy & Market

Digitalisation is changing the logistics landscape

Published

2 days agoon

April 16, 2024By

admin

Haresh Calcuttawala, CEO and Co-Founder, Trezix, explains how their platform streamlines export processes, optimises logistics operations, and addresses the challenges faced by the cement industry.

How does your platform help in the compliance of cement exports?

The Trezix platform helps with the end-to-end processes for exporters, ensuring complete visibility of these processes focusing on shipments, documents, compliances, etc. The platform is also integrated with various stakeholders’ part of the export process including integration with Unified Logistics Integration Platform (ULIP) by the Government of India.

What is the impact of your systems on the cost and productivity of a cement plant?

The Trezix platform helps to optimise the turnaround time, visibility of shipment and improving efficiencies, which results in optimisation in logistics cost and improvement in working capital.

What are the major challenges in logistics and how can that be resolved?

A major challenge in the cement industry is the logistics cost and time for delivery. This can only be resolved with faster turnaround time, complete visibility of shipments, delivery lead time and process control to adhere to compliance.

Tell us your views on the change technology is bringing to logistics.

In the cement industry, so far technology has been more focused on internal process, and optimising demand and supply in the area of supply chain. However, now the focus has completely shifted to external stakeholders and their processes, and how have we integrated processes to further optimise the logistics execution.

Can your systems and solutions be customised based on customer requirements?

Every customer has some unique value proposition for their customer segment. Trezix has flexibility by way of configuration to adhere to industry needs and specific customer needs, keeping in mind the regulatory processes are not deviated to fulfil statutory requirements.

How do you foresee the face of logistics changing for the cement industry?

Digitalisation is one of the biggest waves you can see in the logistics space, which is changing the face of the industry. Digitalisation is changing the logistics landscape. Various concepts like Just In Time (JIT) to customer delivery are now a reality. Vehicle utilisation, fuel efficiency, delivery visibility, vehicle tracking through RFID, Fastag, FOIS (rail receipt tracking), container/cargo tracking across geography is now a reality.

- –Kanika Mathur

Ankit Kumar, Co-Founder and CEO, Skye Air, highlights the advantages of drone deliveries for the cement industry to improve the overall operational efficiency and cost-effectiveness of the supply chain.

What is the environmental impact that drone deliveries can create?

Drone deliveries have the potential to significantly reduce environmental impact compared to conventional delivery methods. By utilising drones, the carbon footprint of last-mile delivery can be slashed by eliminating the need for vehicles and vans, which emit greenhouse gases during transport. In fact, studies have shown that drone deliveries can reduce carbon emissions by up to 80 per cent compared to traditional delivery methods. Additionally, drones provide more direct routes, minimising congestion and further lowering emissions.

Furthermore, Skye Air’s implementation of drone technology can contribute to a substantial decrease in air pollution. Traditional delivery vehicles, powered by fossil fuels, contribute significantly to air pollution, whereas drones operate on cleaner energy sources, such as electricity. As a result, the adoption of drone technology by Skye Air could lead to a notable reduction in harmful pollutants released into the atmosphere.

It’s worth noting that Skye Air is committed to continuous monitoring and optimisation of its operations to ensure that the environmental benefits of drone delivery are maximised. Through data-driven analysis and innovative strategies, Skye Air aims to further enhance the efficiency and sustainability of its drone delivery services.

In conclusion, while drone deliveries offer significant environmental benefits, rigorous management and innovation are essential to mitigate any potential negative effects and ensure the long-term viability of drone delivery operations.

Tell us about the efficiency created by drone delivery systems.

Skye Air has spearheaded a paradigm shift in the logistics industry by substantially augmenting efficiency in their drone deliveries. Drones can help circumvent traditional road networks, bypass traffic congestion and surmount logistical impediments, facilitating expeditious and direct transportation of goods. This heightened efficiency is particularly conspicuous in exigent circumstances, such as the delivery of medical supplies to remote regions or the expeditious fulfillment of urgent orders. By harnessing the capabilities of drones, Skye Air optimises delivery routes, curtails fuel consumption, and mitigates the overall operational costs inherent in conventional delivery methodologies.

Indeed, empirical data underscores the efficacy of drone deliveries, showcasing a significant reduction in delivery times by up to 50 per cent compared to traditional methods. Moreover, drone deliveries have been shown to minimise fuel usage by approximately 60 per cent, contributing to substantial environmental conservation efforts.

Furthermore, the automation of the delivery process not only expedites operations but also bolsters efficiency, resulting in enhanced customer satisfaction rates. With streamlined processes and expedited turnaround times, Skye Air sets a new standard for excellence in the logistics domain.

What is the role of digitalisation and technology in your delivery and transport system?

In Skye Air, digitalisation and technology serve as pivotal catalysts in revolutionising our delivery and transport system. Through the integration of cutting-edge drone technology like Skye UTM, we have established a streamlined and efficient delivery process. Our drones are equipped with state-of-the-art navigation systems and sensors, enabling precise and secure delivery routes. Skye UTM stands as the most advanced and indigenised Aerial Traffic Management platform, designed to furnish situational awareness, autonomous navigation, risk assessment, and traffic management to all drone and aerial mobility operators across the airspace. Skye UTM has already facilitated successful BVLOS (Beyond Visual Line of Sight) drone flights. The Skye UTM captures over 255+ parameters of UAV movements, storing them in its ‘Black box’, which comprises a published systematic description of the entire flight. This platform offers the inaugural 3-Dimensional view of the drone airspace, alongside operations and regulations mapping servers, furnishing the latest airspace status, verified paths, and exhibiting real-time UAV movements. Furthermore, our digital platforms empower customers to seamlessly place orders and track their deliveries in real-time. This digitalisation not only amplifies the velocity and precision of our deliveries but also ensures transparency and accountability throughout the entire process.

Can drone deliveries be incorporated with the cement industry in the future?

In the foreseeable future, the incorporation of drone deliveries holds promise for integration within the cement industry, presenting efficient and swift transportation solutions for materials. The sophisticated drone technology prevalent in logistics stands poised to collaborate seamlessly with cement companies, optimising their supply chain operations. Drones can ferry small batches of cement or other construction materials to remote or challenging-to-access locations, thereby diminishing reliance on conventional transportation modes such as trucks and mitigating logistical complexities. Through the strategic utilisation of drones, the cement industry stands to bolster its efficiency, curtail costs and elevate overall operational efficacy.

- –Kanika Mathur

New appointment at TMEIC

Social Impact Award for Ambuja Cements

UCWL unveils new plant in Dabok, Udaipur

Ambuja Cement hosts ‘Watershed’ event

Cap expansion for Ultratech

Environment Ministry revises rules of solid waste management

M-sand boards new terrain

Process and quality optimization in cement plant.

Concrete: A Highly Sustainable Building Material