Economy & Market

A circular economy is imperative for a sustainable future

Published

4 years agoon

By

admin

Ujjwal Batria, Chief Operating Officer, Dalmia Cement (Bharat)

Give us a brief on the activities of Dalmia Group in the Indian subcontinent regarding AFR.

Cement is an essential commodity in construction and infrastructure development. Although there is some environmental impact during its production, we have always adhered to strict environmental norms and have implemented various measures in line with the evolving technologies to reduce the carbon footprint. In sync with the Swachh Bharat Mission, we make major use of AFR (alternative fuels and raw materials).

Apart from AFR, we use fly ash (thermal power plant waste) and BF Slag (steel industry waste) in our blended cement, which comprises nearly 80 per cent of our product portfolio. Our AFR consumption has more than doubled from 14.5 per cent in FY20 per cent 13-14 to 30 per cent in FY2017-18. Portland Slag Cement and Portland Composite Cement collectively contribute to nearly 50 per cent of our product portfolio. Similarly, our clinker factor has come down to 63 per cent at current levels from about 81 per cent in 2013.

What has been the performance of Dalmia in the last two years in terms of TSR? What do you think about the next three years?

At the group level, we have touched 4 per cent TSR (Thermal Substitution Rate) compared to nearly 0.5 per cent five years ago. We have also developed pockets of excellence in some plants where nearly 18 per cent of TSR has been achieved. Presently, we are utilising various alternative fuels such as biomass, tyre nylon threads, carbon black, spent wash, paint sludge, spent carbon, sawdust as well as waste from cotton, plastic and footwear. While boosting the bottom line, these simultaneously curb GHG (greenhouse gas) emissions from cement operations. Moving forward, we are augmenting our fuel feeding systems with additional investments for making more use of both solid and liquid alternative fuels.

What do you think needs to be done urgently to improve the overall TSR numbers in the country?

Thermal Substitution Rate refers to the percentage of sustainable alternative fuels used in replacing fossil fuels. Commodity materials such as refuse-derived fuel (RDF) improve TSR percentage but lower investment payback. India is targeting 25 per cent TSR by 2025. Yet, compared to global standards (TSR of about 60 per cent to 100 per cent in many countries), we remain far behind. The main issues – waste characteristics and lack of support from the required agency for generating good segregated waste quality.

A circular economy is imperative for a sustainable future. Given its second-largest producer tag, India’s cement industry contributes to the circular process by handling different types of waste – whether it is steel industry slag, municipal solid waste or fly ash. The cement industry can be a mega player in waste management. In 2017-18, its production was 298 MTPA, which is expected to touch more than 550-600 MTPA by 2025. To meet this demand, it requires more than 51 million tonnes of coal that is already in short supply.

Besides, given the Centre’s Swachh Bharat Mission, we should use alternative fuels and raw materials (AFR). Along with the need for AFR, it is essential to use RDF along with other industrial waste, which is anyway a part of kiln feeds. Consequently, RDF offers an immense opportunity to boost the TSR of cement kilns, which could also save millions in foreign exchange due to lower coal imports. From 1 per cent a few years ago, the average TSR is now 4 per cent. The target is 25 per cent by 2025 and 30 per cent by 2030.

Are you handling industrial or any hazardous waste at any of the plants under your control? Kindly provide details.

The country’s cement industry is no longer as polluting or hazardous as some others since a complete transformation has occurred in this sector. A single visit to any of our sites will dispel any preconceived notions about cement plants being most polluting and hazardous.

The environmental emission norms mandated by the Government of India for the cement industry are at par with many developed countries. Cement is a basic building block and an essential glue that binds concrete – the world’s second-most consumed commodity after water. Nonetheless, when any industrial activity takes place on such a scale, some collateral impact on the environment cannot be ruled out. In recent years, however, the industry has made its operations significantly safer.

Overall, the industry is using waste more energy efficiently. The industry consumes almost 50 per cent of the country’s fly ash. Likewise, the steel industry’s entire BF Slag is used by our industry. Many cement plants in India are water positive. In other words, we are providing more water to nature than we take from it. The cement industry is growing by leaps and bounds in promoting sustainable business practices in India. Recently, international climate research rating agency CDP published their report on the global cement sector. CDP ranked six cement companies from India in the Top 10. Dalmia Cement has been ranked No.1 in the CDP report on business readiness for low carbon transition.

More than 65 per cent of cement production capacity in India comes under the Global Cement and Concrete Association (GCCA). The main objective of GCCA is introducing sustainable business practices in the industry. Moreover, safety is the topmost priority. Typically, there is a major shift in providing a safe environment for our employees. Progressive cement companies are implementing a people-first policy, making the safety of workers a priority. Engagement in the supply chain is another area where much progress has been made. Various programmes such as defensive driving and driver passport system have been initiated for greater safety of workers, including during transport-related operations.

Provide more details on the platform created for handling hazardous waste.

Cement kilns deploy co-processing in waste disposal. Unlike landfilling and incineration, this practice is a more sustainable and environment-friendly waste disposal method thanks to the lower emissions and lack of residue after the treatment. Recently, our cement sector has made significant investments in ensuring a greener future via the enhanced use of AFR and other means. But the industry’s contribution is contingent on the progress of the nation’s overall waste management segment.

The progress on the AFR front has been robust, which includes the penetration of blended cements. While OPC (Ordinary Portland Cement) was the market leader in India earlier, today it has only around 20-25 per cent of market share. It is heartening that nearly 75 per cent of the nation’s cement production presently is in the form of various types of blended cement against barely 30 per cent in 1999-2000. The Indian cement industry has more potential to use alternative fuels than is being done currently. Yet, to achieve this, a complete transformation is required in India’s waste management sector from the generation point to disposal methods. Once implemented, the circular economy could become the backbone of India’s waste management practices. There is overwhelming customer acceptance of environment-friendly products. Many States have also come forward and developed policies for greater utilisation of blended cements. On our part, we are continuing policy advocacy and training of masons in using more blended cements and making them sensitive to environmental issues such as climate change. The use of industrial wastes in cement offers the technical advantages of improved durability and lower carbon footprint.

Can hazardous waste and other waste materials go together in the kiln or have to be moved separately?

Cement kilns use co-processing for waste disposal. Unlike landfilling and incineration, this is a more sustainable and environment-friendly waste disposal method due to lower emissions and lack of residue after the treatment. Thereby, waste materials in industrial processes are used as AFRs in recovering material and energy from them. These are fully utilised as a replacement for fossil fuels in cement kilns. Given the high temperatures in cement kilns, various kinds of wastes are disposed of effectively without harmful emissions by co-processing. In many countries, different types of plastic wastes are regularly disposed of in an environmentally-sound manner through co-processing. In essence, hazardous and non-hazardous wastes, which includes plastic wastes, are used as AFRs.

Nonetheless, care is required in selecting wastes and equipment, with trained personnel handling the co-processing of any waste. Tell us something about the pre-processing required for hazardous waste.

Conversion of Segregated Combustible Fraction (SCF) into RDF is done by a waste management operator at the existing waste management site. This comprises setting up a pre-processing facility with storage, shredding and blending operations. The cement company needs to establish a co-processing facility in the plant to ensure its viability. For the plant, the expenditure streams are the pre-processing cost and RDF transportation cost.

In utilising hazardous waste, enormous challenges arise since it’s necessary to have proper inputs from waste generators about the waste characteristics while having a proper material safety data sheet to understand the important precautions during transportation and usage of different wastes.

What has been your experience in moving waste across state borders after the introduction of GST? To what extent the movement has become less painful?

Overall, the introduction of GST has made transport of waste smoother besides reducing the compliance costs as well as complexity. Earlier, due to multiple state entry taxes and CST, it was more cost-effective in maintaining multiple warehouses in different states. But the higher number of warehouses meant most were operating below capacity, creating operational inefficiencies. GST has made this practice redundant as companies benefit by consolidating and maintaining warehouses wherever it is more beneficial. This has thus boosted operational efficiencies.

Additionally, there is a reduction in transit time as vehicles now spend less time idling at checkpoints. In turn, this has lowered logistics costs. Taking these factors into account, movement of waste is less cumbersome for cement companies today.

It is said processing of any kind of waste is not a problem but the issue is of logistics and getting waste at the plant at the right price. How do you think the problem can be solved?

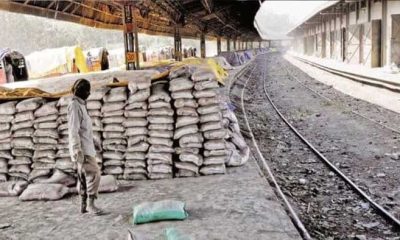

For an industry holding 10 per cent global market share and as the third-largest volume product loader of the Indian Railways, multi-modal transport options are crucial. In comparison with other industries, as a per centage of sales, cement holds the highest logistics cost. This cost soars when the material is unloaded and transported further via road and if it is brought from or taken to the hinterland. The industry requires solutions for controlling transport costs since it comprises about 20% of retail cement prices. Therefore, automation of key processes vis-a-vis monitoring and controls could provide savings in freight costs. Some initiatives can include planned transport deploying intelligent algorithms as well as smart monitoring in implementing operations via GPS technologies.

Wherever possible, Railways should be used for transport as it is the most economical form. Such a focused approach can yield cost benefits. Meanwhile, initiatives are being undertaken by the Railways to ease movement of goods – whether raw materials or finished products. Development of mega stations and dedicated freight corridor will also be useful in boosting cement logistics. More cement manufacturers are now inking long-term freight contracts with the Railways, which will lead to a significant reduction in operating costs.

Do you think that Indian plants have been handling waste in a safe manner that will not cause harm to society in general?

While supply, segregation, quality and consistency are important in handling waste safely, segregation is the most important. Segregation and management at source are generally the best means of managing waste. Thereafter, waste quality and consistency are essential for effective disposal. While existing norms are adequate, the focus needs to be on proper implementation. Standardisation of waste disposal norms could facilitate greater safety while ensuring the cement sector leaves a lower carbon trail.

Economy & Market

RAHSTA to showcase cutting-edge road construction tech, says NCC Director

Published

16 hours agoon

April 19, 2024By

admin

14th RAHSTA (Roads and Highways Sustainable Technologies & Advancement) Expo – India’s biggest road exhibition – will be held as a part 10th India Construction Festival 2024 at Jio Convention Centre, Mumbai, from October 9-10, 2024.

April 10, 2024, Delhi

“The RAHSTA expo will offer extensive information about the latest technology and methods for constructing high-quality roads. Currently, the challenge facing the roads industry is to uphold road quality and execute projects efficiently. RAHSTA will provide opportunities for everyone to learn about the latest worldwide technologies and equipment available, undoubtedly offering valuable insights to those involved in the roads sector,” said Vinod Kumar Yadav, Director – Transport, NCC, and former Chairman, Railway Board, while speaking during the launch of a road show – 14th RAHSTA Expo, which will be held from October 9-10, 2024, at Jio Convention Centre, Mumbai.

RAHSTA, which stands for Roads and Highways Sustainable Technologies & Advancement, is a dedicated event to the world of road construction equipment, technology, and sustainability.

“The Ministry of Road Transport & Highways has constructed 12,349 km of national highways in 2023-24 – the second highest achievement! In 2020-21 a record 13,327 kms had been constructed, the highest so far. The experience of a well-constructed road is no accident but a badly constructed one can cause many,” stated Pratap Padode, Founder, FIRST Construction Council, a pioneering infrastructure-driven council focused on advancing India’s infrastructure development.

Also speaking at the launch, former Managing Director of Ashok Leyland & JCB, Vipin Sondhi, also Chairman of RAHSTA Expo Committee underscored the need for specialised platforms like RAHSTA Expo for the burgeoning road construction industry.

Ashish Kumar Singh, CGM – Finance, National Highway Authority of India; RK Pandey, former NHAI member and Member of RAHSTA Expo Committee; SK Nirmal, Secretary General, Indian Roads Congress and Member of RAHSTA Expo Committee; Prof Satish Pandey, Principal Scientist, CSIR-Central Road Research Institute, Ministry of Science and Technology; Ankit Jain, CFO, Cube Highways Growth Advisors, Vijay Agrawal, Executive Director, Equirus Capital; and Subodh Dixit, Former Executive Director, Shapoorji Pallonji, participated in a round table discussion on the new BOT proposals.

The launch function at PHD Chamber for RAHSTA Expo was attended by who’s who of the infrastructure industry such Lt Gen Harpal Singh, President, International Road Federation and former Engineer-in-Chief, Indian Army; Akhilesh Srivastava, Road Safety Ambassador, International Road Federation; Sandeep Singh, Managing Director, Tata Hitachi Construction Machinery; Rajesh Menon, Director General, Society of Indian Automobile Manufacturers; Raman Kapil, President, Tata Projects; Anand Sundaresan, Director, Ammann India; Dheeraj Panda, Managing Director, Ammann India; Rajan Aiyer, Managing Director, Trimble; Satin Sachdeva, Founder & Secretary General, Construction Equipment Rental Association; Dr Swamy, Chairman, The Institution of Civil Engineers and Dr Ranjeet Mehta, Executive Director of PHDCCI, among others.

Organised by the FIRST Construction Council, the RAHSTA Expo 2024, which will be held as part of 10th India Construction Festival, will bring together industry leaders, innovators, and stakeholders for two days of exploration, collaboration, and transformation.

Besides RAHSTA Expo 2024, the India Construction Festival 2024 will include the following:

- 14th India RAHSTA(Roads) Conference

- 12th Equipment India Awards

- 22nd Construction World Global Awards

Exhibitors can use RAHSTA Expo 2024 to showcase their construction machinery, building material machines, mining machines, and construction vehicles to a targeted audience of industry professionals. RAHSTA Expo will be an ideal platform to connect with key decision-makers, generate leads, and grow business in this rapidly expanding market.

Contact:

For exhibitor enquiries (for RAHSTA Expo), contact Mr Sujoy on Mob: +91 86577 95881, or Email: sujoy.g@asappinfoglobal.com

For delegate enquiries (for conferences), contact Mr Amar on Mob: +91 86524 93000, or Email: delegate1@asappinfoglobal.com

Economy & Market

RAHSTA will drive road construction innovation: Sundaresan

Published

2 days agoon

April 18, 2024By

admin

14th RAHSTA (Roads and Highways Sustainable Technologies & Advancement) Expo – India’s biggest road exhibition – will be held as a part 10th India Construction Festival 2024 at Jio Convention Centre, Mumbai, from October 9-10, 2024.

April 10, 2024, Delhi

“We believe RAHSTA is the ideal platform for our presence, and we are confident in our participation in the upcoming expo scheduled for October,” said Anand Sundaresan, Director, Ammann India, while speaking during the launch of a road show – 14th RAHSTA Expo, which will be held from October 9-10, 2024, at Jio Convention Centre, Mumbai. RAHSTA, which stands for Roads and Highways Sustainable Technologies & Advancement, is a dedicated event to the world of road construction equipment, technology, and sustainability.

Sundaresan added, “We predominantly specialise in road construction machinery, such as asphalt plants, concrete batching plants, pavers, and rollers, among others. Additionally, we offer ancillary equipment like supers. With the government placing significant emphasis on infrastructure development, there is a substantial demand for road construction machinery. Particularly noteworthy is the growth witnessed in the last year (2023-2024), with a surge in orders. Moreover, the construction of airports is underway, necessitating equipment for runway construction. We perceive immense potential and opportunity for growth within the industry.”

“The Ministry of Road Transport & Highways has constructed 12,349 km of national highways in 2023-24 – the second highest achievement! In 2020-21 a record 13,327 kms had been constructed, the highest so far. The experience of a well-constructed road is no accident but a badly constructed one can cause many,” stated Pratap Padode, Founder, FIRST Construction Council, a pioneering infrastructure-driven council focused on advancing India’s infrastructure development.

Padode was speaking at the launch of a road show – 14th RAHSTA Expo, which will be held from October 9-10, 2024, at Jio Convention Centre, Mumbai. RAHSTA, which stands for Roads and Highways Sustainable Technologies & Advancement, is a dedicated event to the world of road construction equipment, technology, and sustainability.

Speaking at the launch, former Managing Director of Ashok Leyland & JCB, Vipin Sondhi, also Chairman of RAHSTA Expo Committee underscored the need for specialised platforms like RAHSTA Expo for the burgeoning road construction industry.

Ashish Kumar Singh, CGM – Finance, National Highway Authority of India; RK Pandey, former NHAI member and Member of RAHSTA Expo Committee; SK Nirmal, Secretary General, Indian Roads Congress and Member of RAHSTA Expo Committee; Prof Satish Pandey, Principal Scientist, CSIR-Central Road Research Institute, Ministry of Science and Technology; Ankit Jain, CFO, Cube Highways Growth Advisors, Vijay Agrawal, Executive Director, Equirus Capital; and Subodh Dixit, Former Executive Director, Shapoorji Pallonji, participated in a round table discussion on the new BOT proposals.

The launch function at PHD Chamber for RAHSTA Expo was attended by who’s who of the infrastructure industry such Lt Gen Harpal Singh, President, International Road Federation and former Engineer-in-Chief, Indian Army; Akhilesh Srivastava, Road Safety Ambassador, International Road Federation; Sandeep Singh, Managing Director, Tata Hitachi Construction Machinery; Rajesh Menon, Director General, Society of Indian Automobile Manufacturers; Raman Kapil, President, Tata Projects; Anand Sundaresan, Director, Ammann India; Dheeraj Panda, Managing Director, Ammann India; Rajan Aiyer, Managing Director, Trimble; Satin Sachdeva, Founder & Secretary General, Construction Equipment Rental Association; Dr Swamy, Chairman, The Institution of Civil Engineers and Dr Ranjeet Mehta, Executive Director of PHDCCI, among others.

Organised by the FIRST Construction Council, the RAHSTA Expo 2024, which will be held as part of 10th India Construction Festival, will bring together industry leaders, innovators, and stakeholders for two days of exploration, collaboration, and transformation.

Besides RAHSTA Expo 2024, the India Construction Festival 2024 will include the following:

- 14th India RAHSTA(Roads) Conference

- 12th Equipment India Awards

- 22nd Construction World Global Awards

Exhibitors can use RAHSTA Expo 2024 to showcase their construction machinery, building material machines, mining machines, and construction vehicles to a targeted audience of industry professionals. RAHSTA Expo will be an ideal platform to connect with key decision-makers, generate leads, and grow business in this rapidly expanding market.

Contact:

For exhibitor enquiries (for RAHSTA Expo), contact Mr Sujoy on Mob: +91 86577 95881, or Email: sujoy.g@asappinfoglobal.com

For delegate enquiries (for conferences), contact Mr Amar on Mob: +91 86524 93000, or Email: delegate1@asappinfoglobal.com

TMEIC Industrial Systems India, a Group company of TMEIC Corporation, Japan, has announced the appointment of Hidekazu Matsushima as the new Managing Director. Matsushima has been associated with Mitsubishi Electric FA division for domestic market in Japan since 1991 and been assigned in Industrial division in 1994, where he rolled out his mission of sales, marketing and business development of General industry (GI) such as paper, film, Oil & Gas, petrochemical, cement, food, automobile, semiconductor industries in Japan. During the establishment of TMEIC in Japan in 2003, he was assigned with the responsibility for domestic GI market Sales in Japan HQ, and then in plant and energy sales department.

RAHSTA to showcase cutting-edge road construction tech, says NCC Director

RAHSTA will drive road construction innovation: Sundaresan

New appointment at TMEIC

Social Impact Award for Ambuja Cements

UCWL unveils new plant in Dabok, Udaipur

Environment Ministry revises rules of solid waste management

M-sand boards new terrain

Process and quality optimization in cement plant.

Concrete: A Highly Sustainable Building Material